Intermediate fixture and method for semiconductor laser failure analysis sample preparation

A failure analysis sample and laser technology, applied in the field of optical communication, can solve the problem of low sample preparation rate of semiconductor laser failure analysis samples, and achieve the effect of improving sample preparation effect, easy operation and improving grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

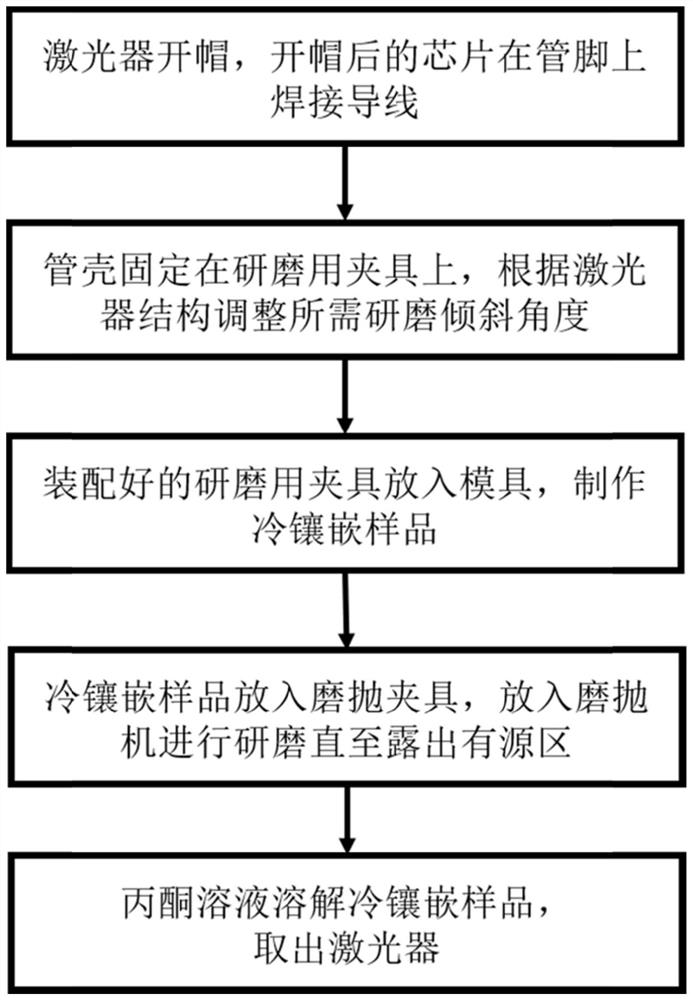

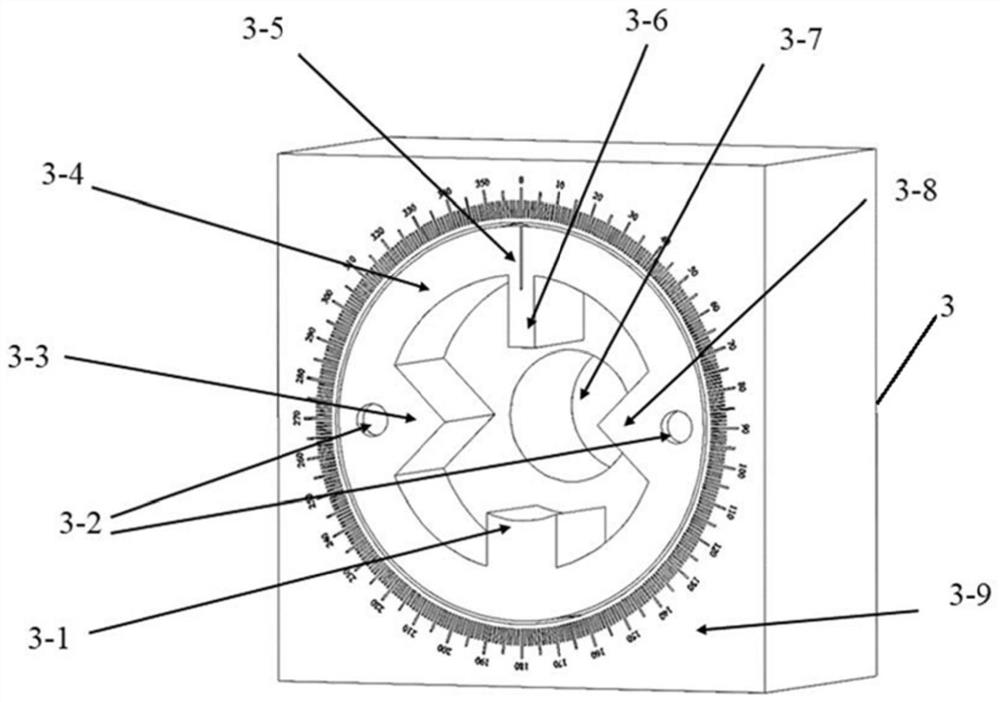

Method used

Image

Examples

Embodiment 1

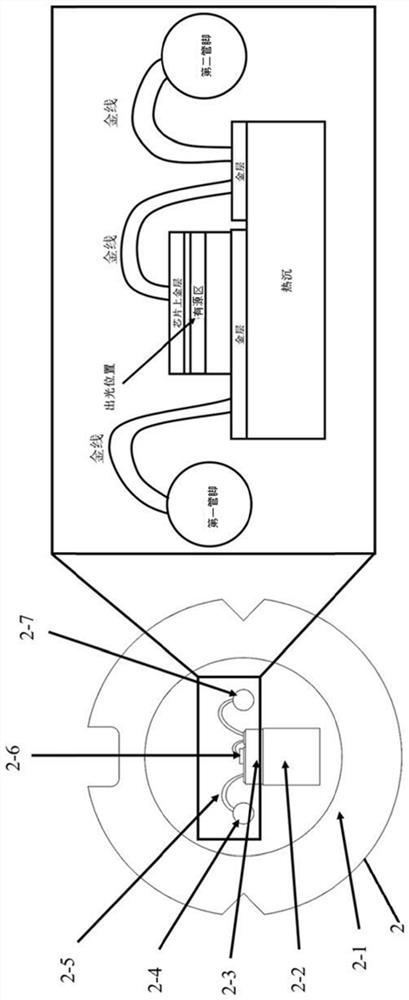

[0064] In this embodiment, the semiconductor laser failure analysis sample is prepared by the above method, wherein, since the height h=100 μm and the width W=200 μm of the TO laser, the formula 0 Figure 8 and Figure 9 shown.

[0065] The failure analysis sample of the semiconductor laser is subjected to a power-on test, that is, one end of the DC current source power supply is connected to the wire of the first pin, and the other end is added to the gold layer on the chip through a probe, and then a certain current (higher than that of the TO laser) is injected. Threshold current), the electroluminescence image of the active region is obtained, so that the effective analysis of semiconductor lasers can be realized.

Embodiment 2

[0067] This example uses the same method as in Example 1 to prepare a semiconductor laser failure analysis sample, wherein the rotation angle α' is selected as a complementary rotation angle to α in Example 1, and finally the top view of the semiconductor laser failure analysis sample obtained by grinding and dissolving and front view respectively as Figure 10 and Figure 11 shown.

[0068] The failure analysis sample of the semiconductor laser is subjected to a power-on test, that is, one end of the DC current source power supply is connected to the wire or pad of the second pin, the other end is added to the gold layer under the chip through a probe, and then a certain current (high The current at the threshold of the TO laser), the electroluminescence image of the active region is obtained, so that the effective analysis of the semiconductor laser can be realized.

[0069]The semiconductor laser failure analysis sample obtained by the intermediate fixture and method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com