Flash memory manufacturing method

A manufacturing method and memory technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of difficult programming operation of chips, low current, low mobility, etc., and achieve good isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

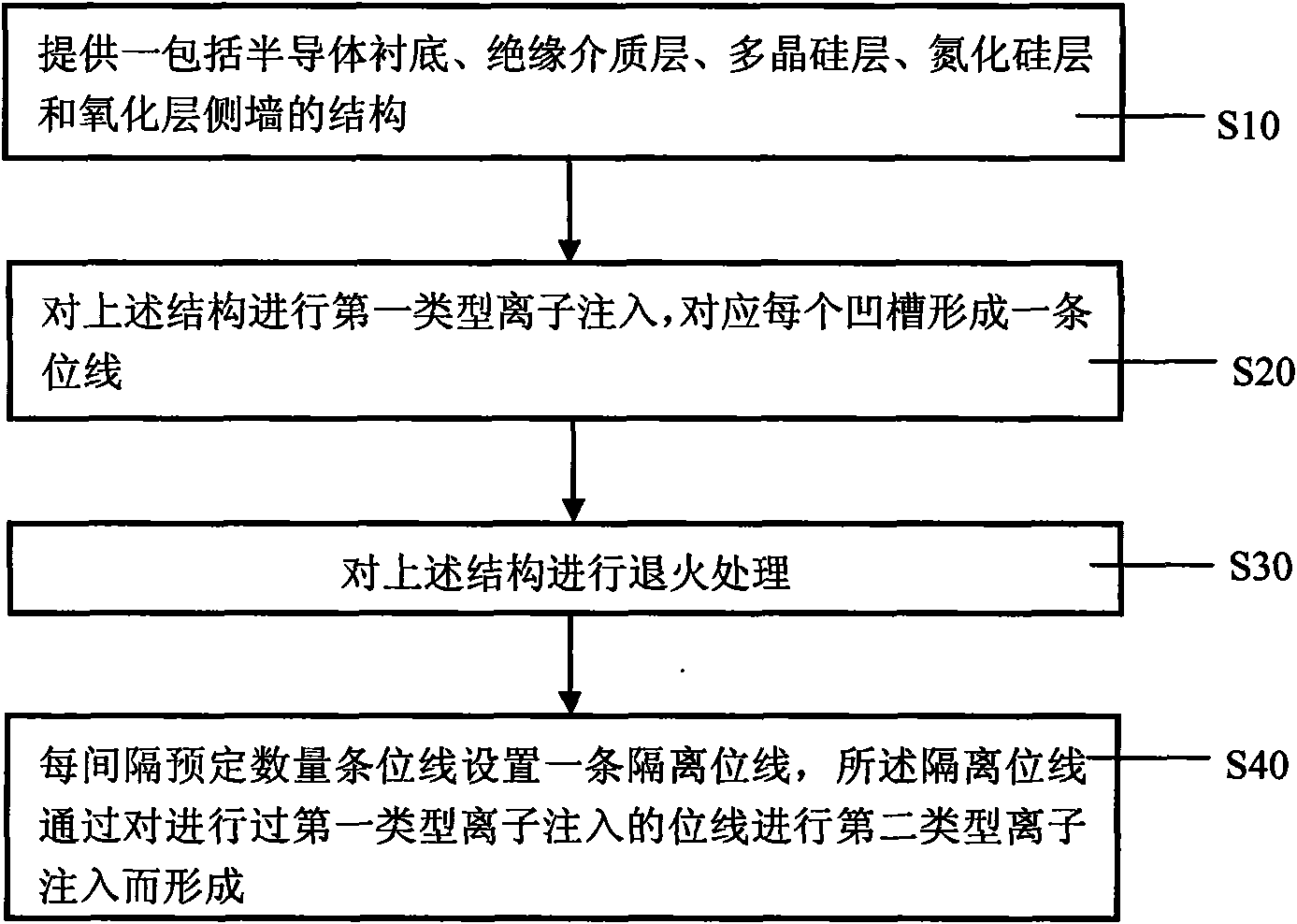

[0035] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

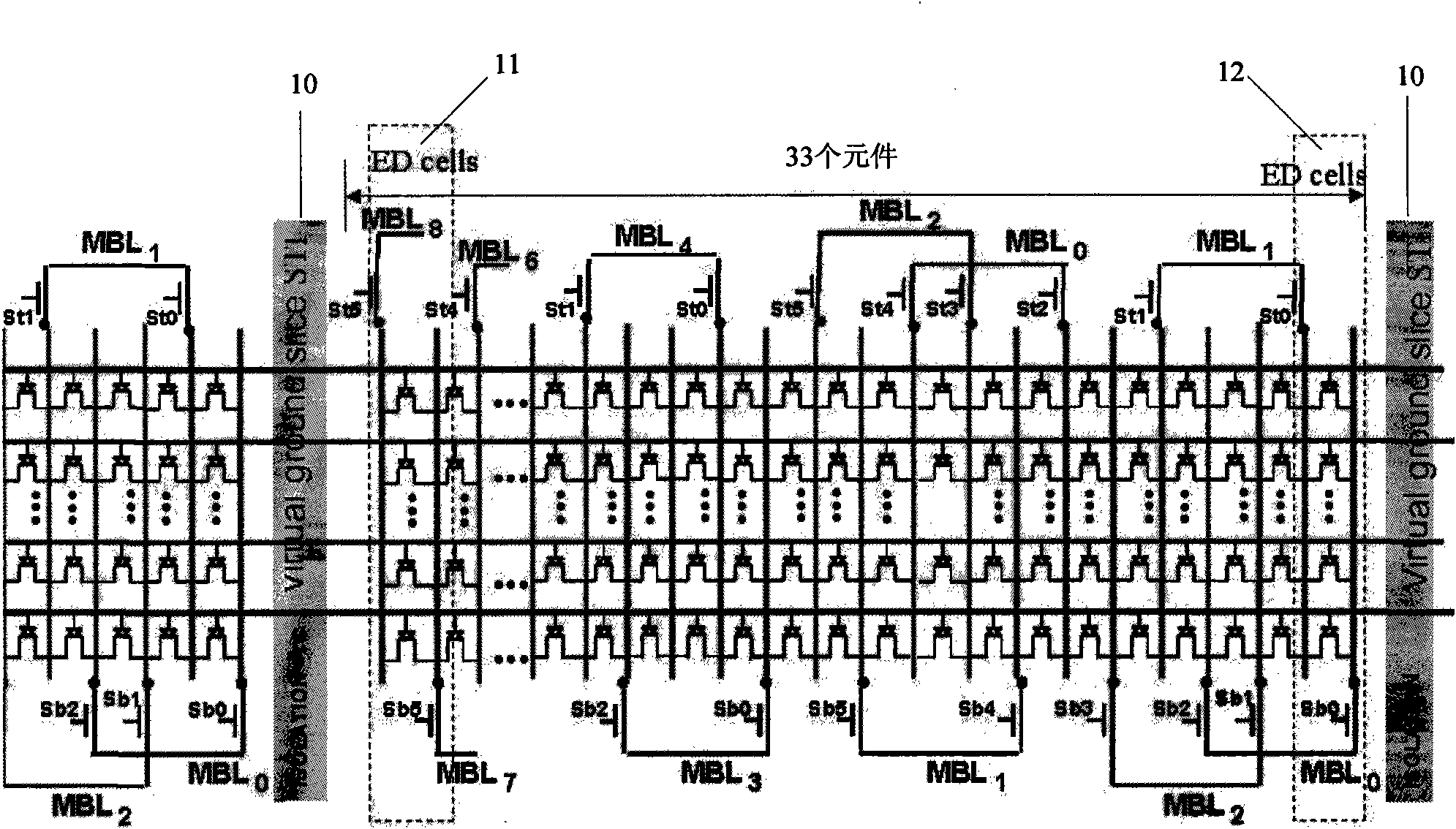

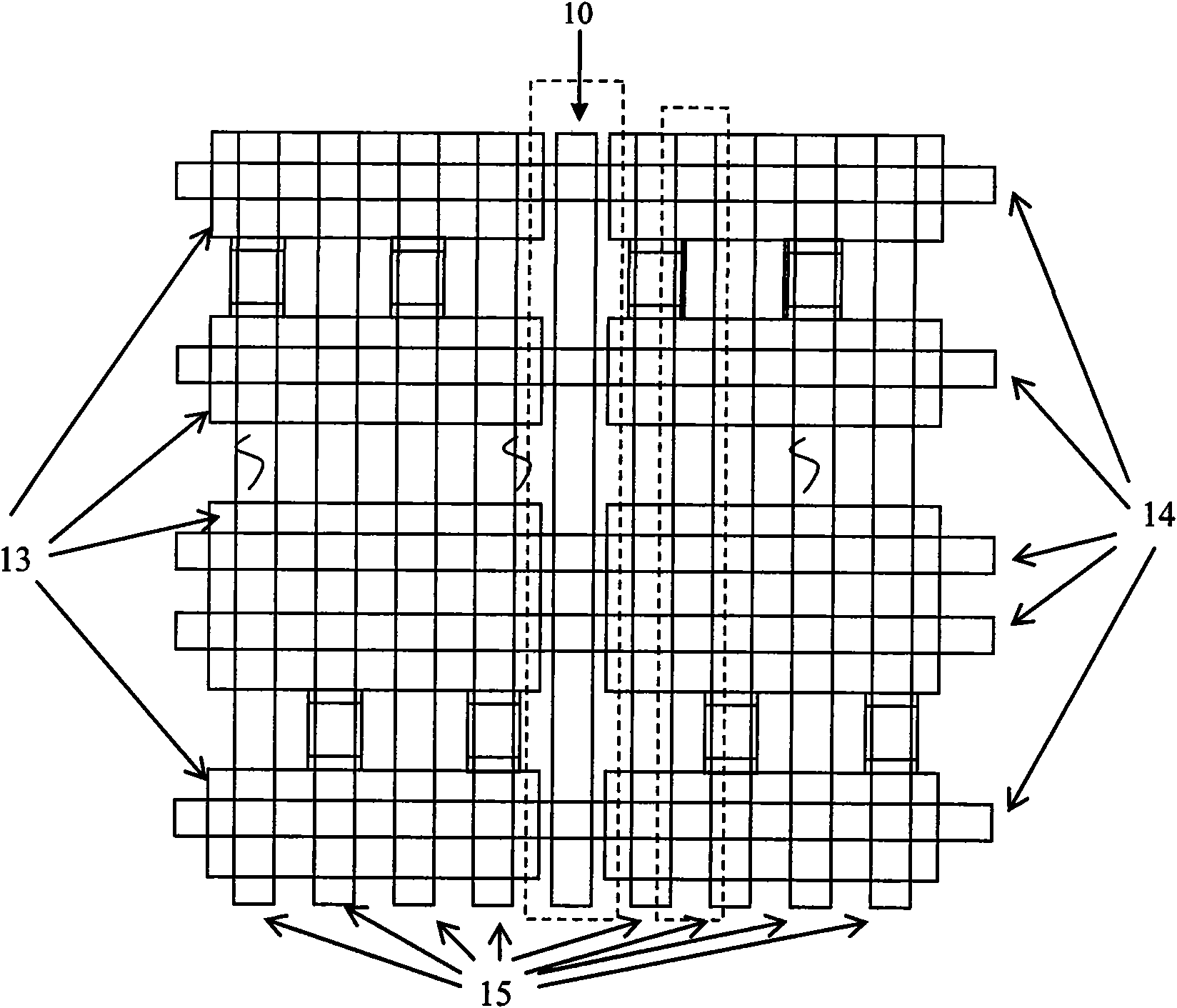

[0036] The core idea of the present invention is that, based on the existing storage structure of the flash memory, through different types of ion implantation, a bit with an isolation effect is formed between groups composed of a predetermined number (16-50) of storage cells. line, thereby replacing the shallow trench isolation structure used in the prior art, while achieving the same effect of using shallow trench isolation to solve adjacent interference, it can also avoid the generation of mechanical stress, thereby improving the performance of the flash memory .

[0037] The invention proposes a manufacturing method of flash memory, which can achieve the same effect of using shallow trench isolation without generating mechanical stress.

[0038] Please refer to image 3 , image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com