Non-destructive grinding method and device for welding column of CCGA device

A device and welding post technology, which is applied in the field of non-destructive grinding method and device for welding posts of CCGA devices, can solve the problems of sidewall damage, poor verticality of welding posts, difficult assembly, etc. Stable seal structure and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

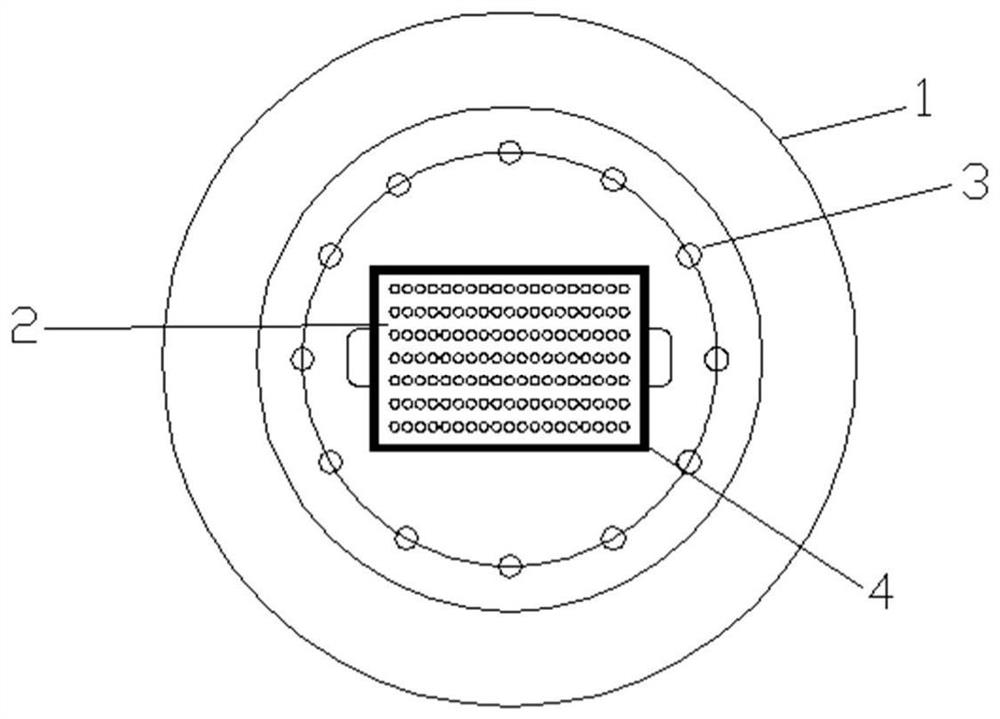

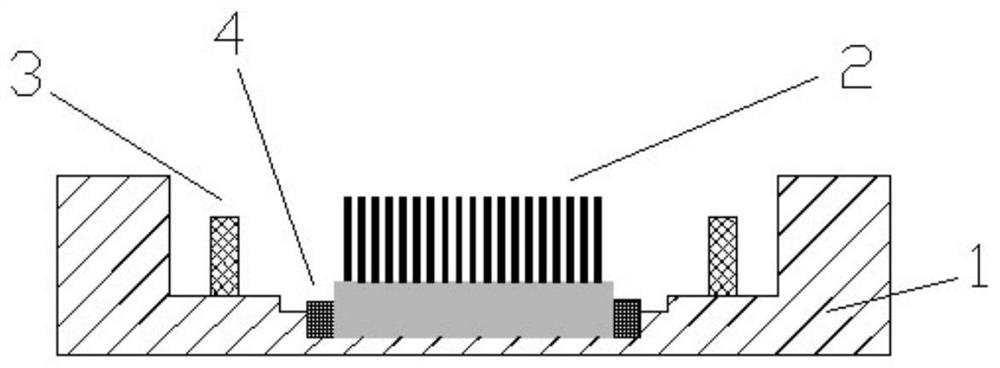

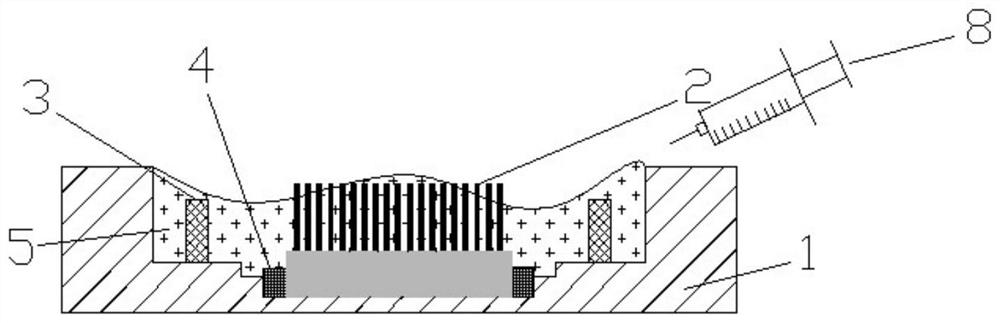

[0036] The present invention is described in further detail below in conjunction with accompanying drawing:

[0037] A method for non-destructive grinding and flattening of welding posts of CCGA devices, comprising the following steps:

[0038] S1, positioning and fixing the CCGA device to be trimmed, and then potting the welding post of the CCGA device to be trimmed with injection molding resin;

[0039] Specifically, the CCGA device to be trimmed is positioned and fixed by using the grinding tooling, which is a concave structure, and the CCGA device to be trimmed is fixed in the groove of the grinding tooling, and the groove depth of the grinding tooling is greater than that of the CCGA device to be trimmed. The height of the column, that is, the CCGA device to be trimmed is put into the grinding tooling, and the welding column of the CCGA device to be trimmed is lower than the upper plane of the grinding tooling; the groove structure of the grinding tooling is used to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com