Trimming mechanism based on automobile injection molding part

A technology for injection molded parts and trimming, which is applied to machine tools, household components, applications, etc., which are suitable for grinding the edge of workpieces. It can solve the problems of reducing processing efficiency and increasing labor, and achieves reducing processing efficiency, increasing labor, and convenience The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

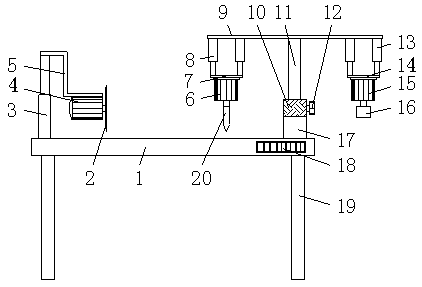

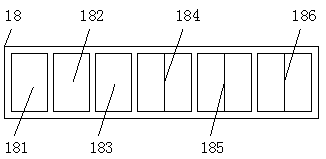

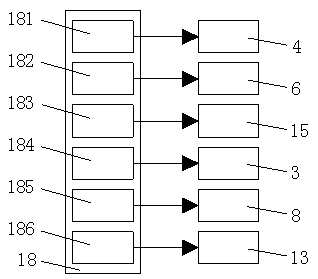

[0016] refer to Figure 1-3 , the present invention comprises a support seat 1, the support legs 19 are fixedly connected around the bottom of the support seat 1, and the bottom of the support legs 19 is fixedly connected with a rubber pad, and the right end of the front surface of the support seat 1 is fixedly connected with a controller 18, and the control The front surface of the device 18 is fixedly connected with the first motor switch 181, the second motor switch 182, the third motor switch 183, the first telescopic control button 184, the second telescopic control button 185 and the third telescopic control button from left to right. 186, the left end of the top of the support seat 1 is fixedly connected with the first electric telescopic rod 3, and the top of the first electric telescopic rod 3 is fixedly connected with the first support plate 5, and the bottom of the first support plate 5 is fixedly installed with the first motor 4 , and the output shaft of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com