Processing equipment for cut velvet fabric and operating method of processing equipment

A technology for processing equipment and cutting velvet cloth, which is applied to textiles, papermaking, and fabric surface trimming, etc. It can solve the problems of strong limitations of velvet cutting technology, reduced equipment utilization space, and chaotic equipment operation methods, so as to increase the scope of use and improve the application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

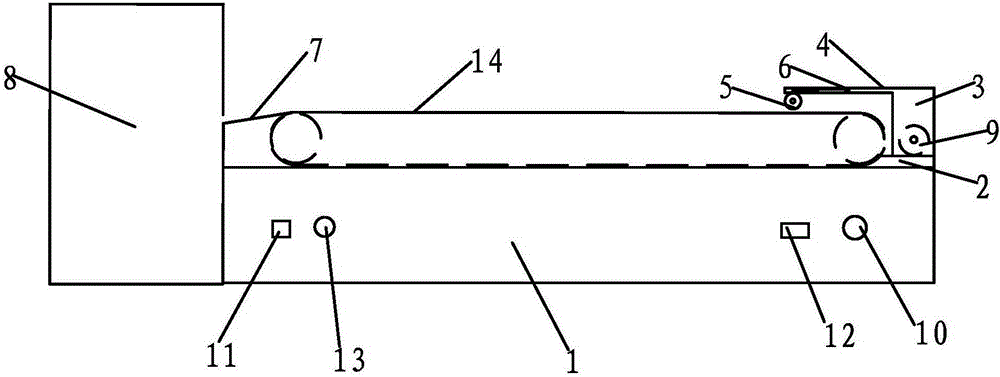

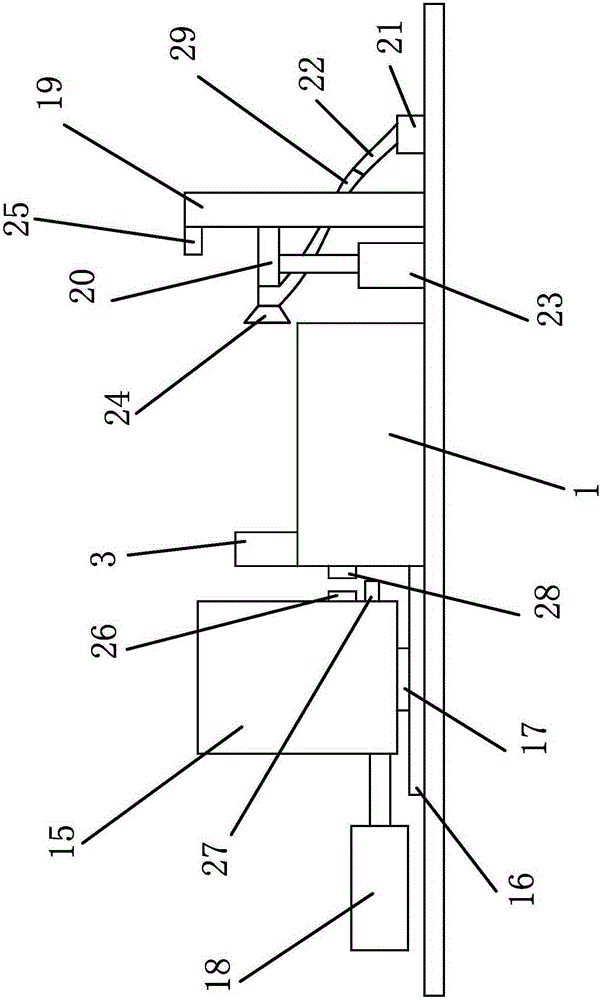

[0027] Such as figure 1 As shown, a cut velvet cloth processing equipment includes a box body 1, the upper surface of the box body 1 is provided with a cut velvet platform 2, and a row of lifting frames are respectively arranged on both sides of the cutting velvet platform 2, and the top of the lifting frame is hinged with a limit bar , one side of the cut velvet platform 2 is provided with a cutting mechanism, the cutting mechanism includes a support frame, the support frame includes a vertical support plate 3 and a horizontal support plate 4, one side of the vertical support plate 3 is a height adjustment surface, and the horizontal support plate 4 along the height The sliding action of the adjustment surface, the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com