Energy storage power station system with good heat dissipation effect

A technology for energy storage power stations and heat dissipation effects, which is applied in vehicle energy storage, power distribution substations, substation/switch layout details, etc., can solve problems such as poor heat dissipation effects of energy storage power stations, improve heat dissipation efficiency, speed up heat dissipation, and speed up The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

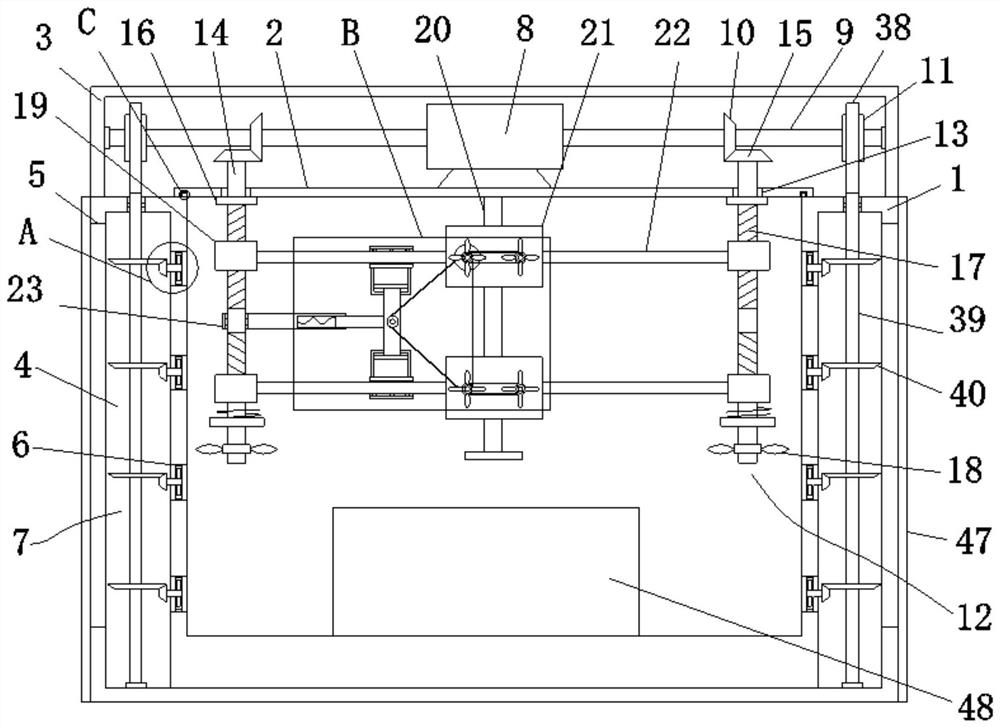

[0032] Embodiment one, by Figure 1 to Figure 6 Given, the present invention comprises a container box body 1, the top of the container box body 1 is connected with a sealing plate 2, the top of the container box body 1 is provided with a box cover 3 sleeved on the outside of the sealing plate 2, the two sides of the container box body 1 The empty slot 4 is symmetrically opened, the outer wall of the container box 1 is provided with an opening 5 communicating with the empty slot 4, and the inner wall of the container box 1 is equidistantly provided with a port 6 communicating with the empty slot 4, and the two empty slots The inside of 4 is equipped with heat absorbing mechanism 7, the inner bottom of container box 1 is provided with electric energy equipment 48, and the inner two sides of container box 1 are symmetrically provided with blowing mechanism 12;

[0033] The top of sealing plate 2 is provided with biaxial motor 8, and the output shaft of biaxial motor 8 is all con...

Embodiment 2

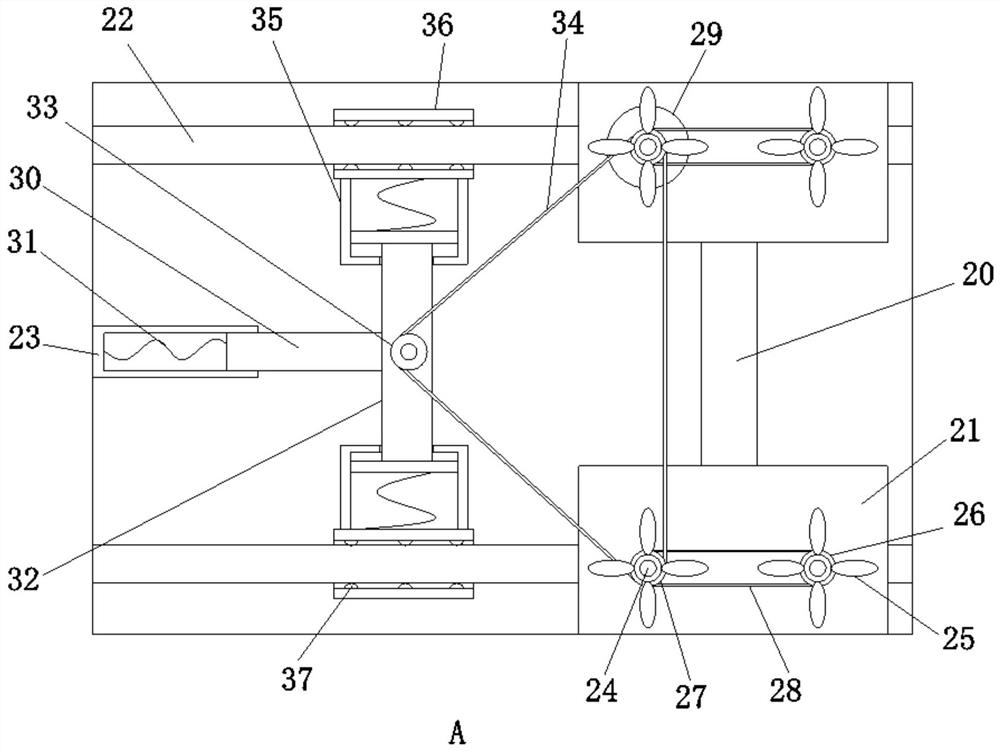

[0035] Embodiment two, on the basis of embodiment one, by figure 1 and image 3Given, the middle position of the bottom end of the sealing plate 2 is provided with a slide bar 20, and the slide bar 20 is symmetrically sleeved with a movable seat 21, and the two sides of the movable seat 21 are respectively connected to the side walls of the two sliders 19 through connecting rods 22, Through the design of the slide bar 20 , the movable seat 21 and the connecting rod 22 , it is convenient to install the radiator, and at the same time to bring convenience to the heat dissipation work of the radiator, thereby improving the heat dissipation efficiency of the electric energy equipment 48 .

Embodiment 3

[0036] Embodiment three, on the basis of embodiment one, by figure 1 Given, the bottoms of the two two-way screw rods 17 are provided with a buffer group, the buffer group includes a stop plate and a buffer spring, the stop plate is fixedly sleeved on the two-way screw rod 17, and the top of the stop plate is provided with a sleeve The buffer spring on the outside of the two-way screw rod 17 is convenient to limit the position of the slider 19 through the design of the stopper plate and the buffer spring, and at the same time can alleviate the collision force between the slider 19 and the stopper plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com