Apparatus for removing particulate matter

a technology of particulate matter and apparatus, which is applied in the direction of physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, and separation processes, etc., can solve the problems of mounting a large apparatus onto a movable body, providing sufficient effect to reduce burning temperature, etc., and achieve and excellent oxygen releasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

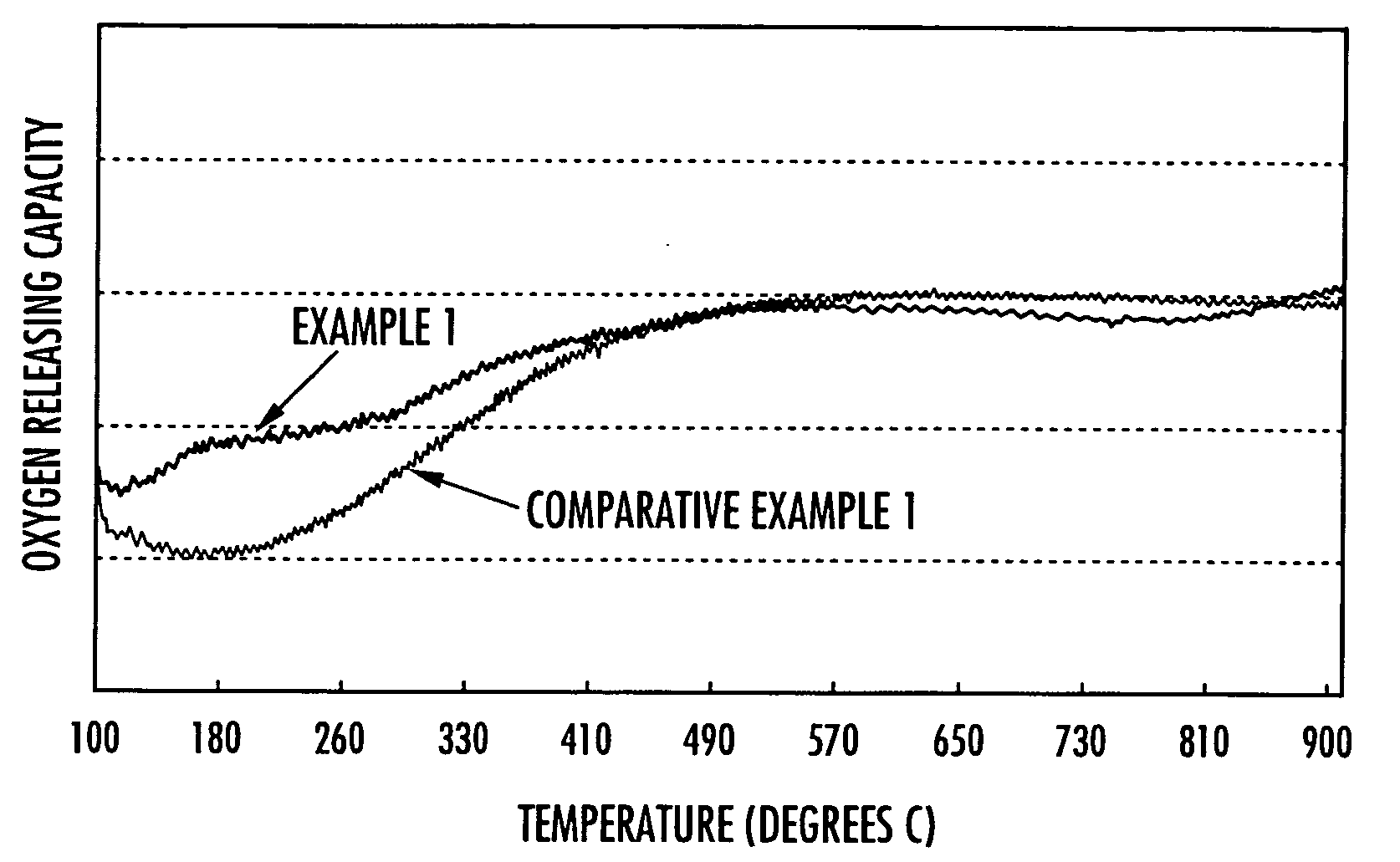

example 1

[0028] First, in this example, equimolar quantities of lanthanum nitrate and manganese (III) nitrate, and four-fold molar excess of urea of a metal salt were dissolved in a small amount of water, and the solution was poured into a porcelain pot for a primary firing for two hours at 350° C. and further a secondary firing for one hour at 1000° C., which resulted in a perovskite-type complex oxide represented by LaMn(III)O3. Next, the temperature of the resulting perovskite-type complex oxide of this example was raised from an ambient temperature to 900° C. at the rate of 10° C. / minute in a vacuum of 1.33×10−5 Pa, and oxygen releasing capacity of the oxide was measured. The oxygen releasing capacity was determined, by measuring the oxygen which was desorbed during the above raise of temperature as a mass spectrum intensity of a mass-to-charge ratio (m / z)=32 with a mass analyzer. The result is shown in FIG. 1.

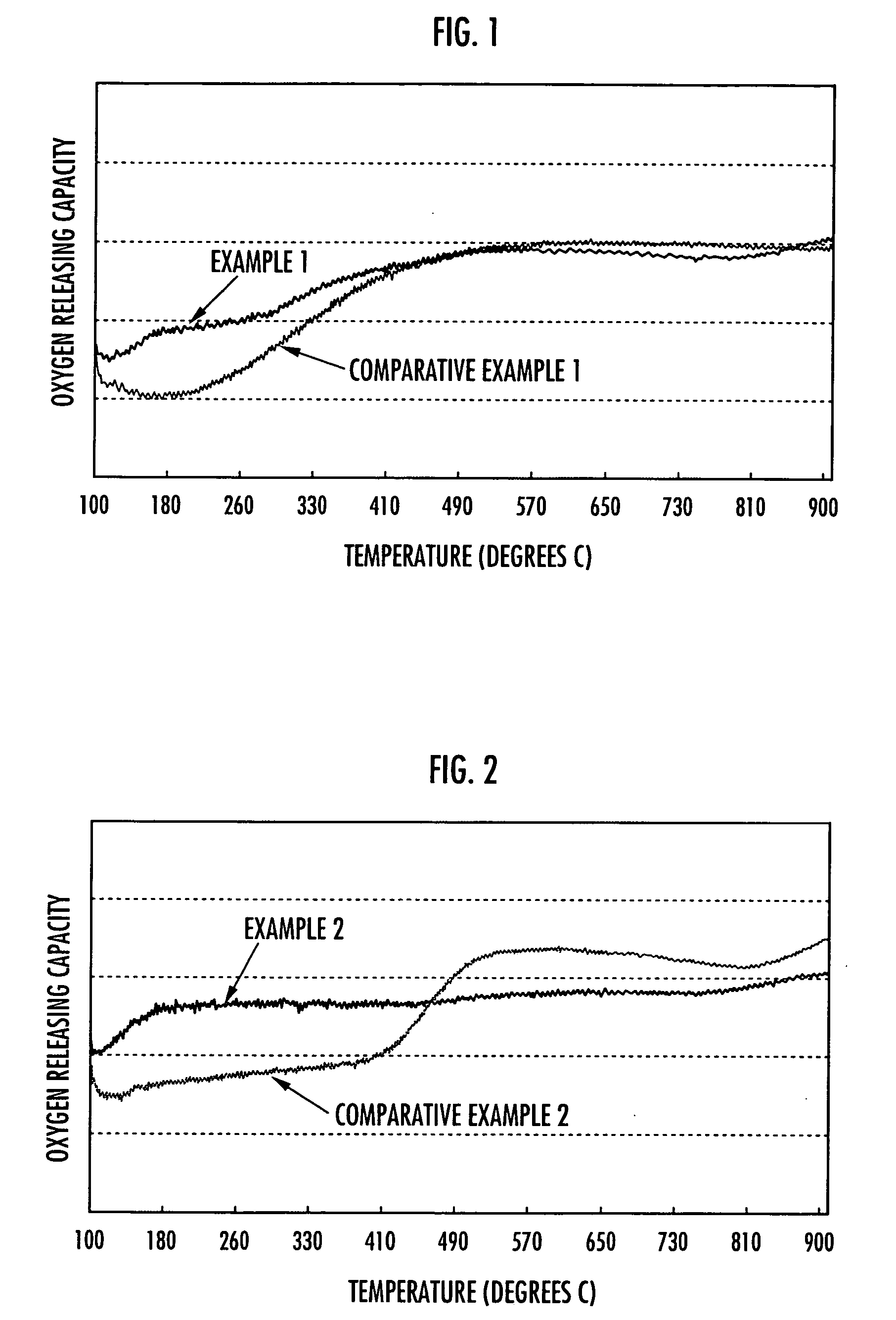

example 2

[0030] First, in this example, equimolar quantities of lanthanum nitrate, manganese (III) nitrate and strontium nitrate, and four-fold molar excess of urea of a metal salt were dissolved in a small amount of water, and the solution was poured into a porcelain pot for a primary firing for two hours at 350° C. and further a secondary firing for one hour at 1000° C., which resulted in a perovskite-type complex oxide represented by LaSrMn(II)O3. Next, the oxygen releasing capacity of the resulting perovskite-type complex oxide in this example was measured in the same manner as in Example 1. The result is shown in FIG. 2.

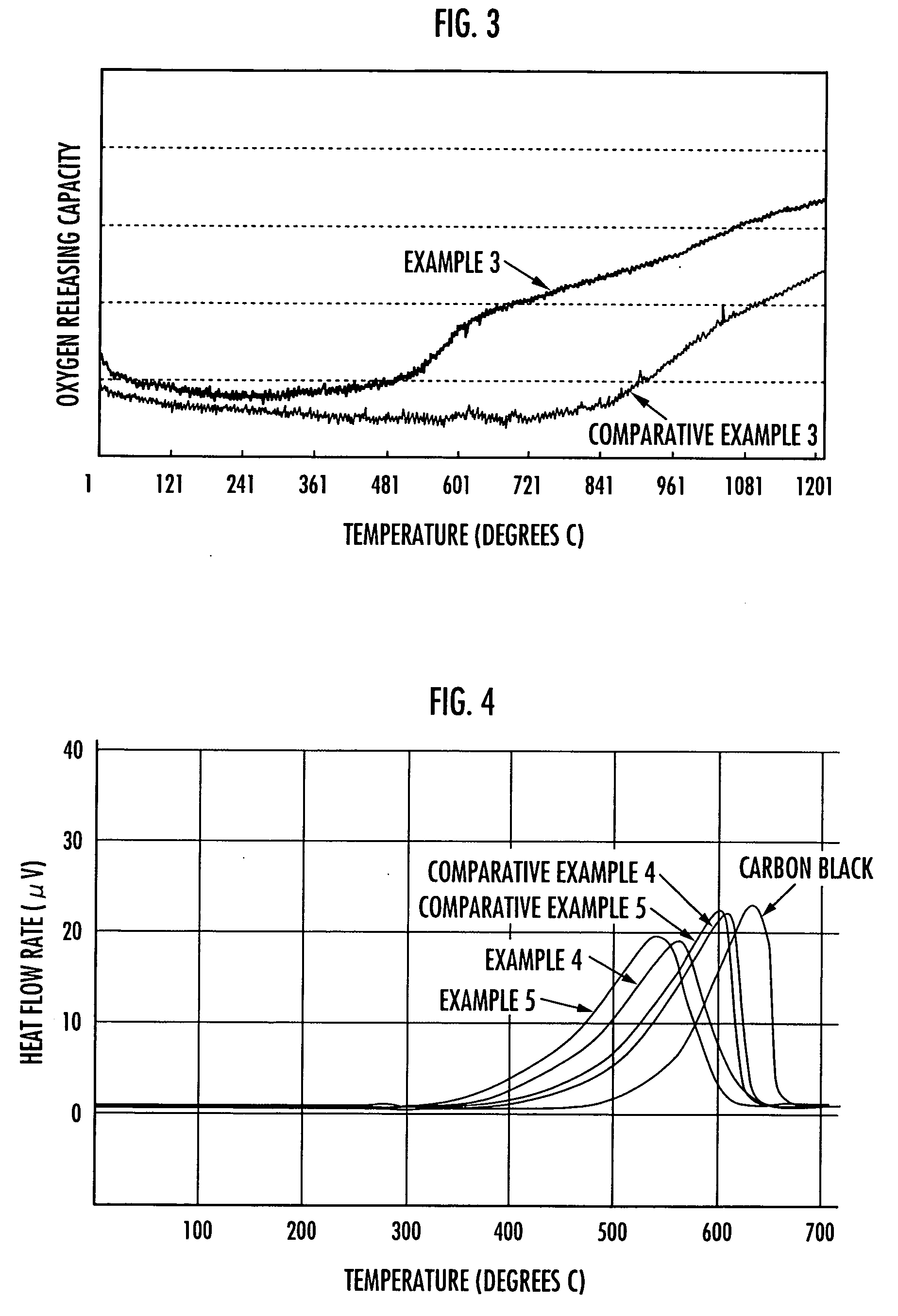

example 3

[0032] First, in this example, equimolar quantities of lanthanum nitrate and cobalt (III) nitrate, and four-fold molar excess of urea of a metal salt were dissolved in a small amount of water, and the solution was poured into a porcelain pot for a primary firing for two hours at 350° C. and further a secondary firing for one hour at 1000° C., which resulted in a perovskite-type complex oxide represented by LaCo(III)O3. Next, the oxygen releasing capacity of the resulting perovskite-type complex oxide in this example was measured in the same manner as in Example 1. The result is shown in FIG. 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Valence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com