Non-quenched-tempered ocean engineering structure pipe with steel grade of more than 360MPa

An offshore engineering, non-quenching and tempering technology, applied in the field of offshore drilling platforms, can solve problems such as increasing the production process cost of seamless steel pipes, and achieve the effects of improving market competitiveness, reducing process costs, and releasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

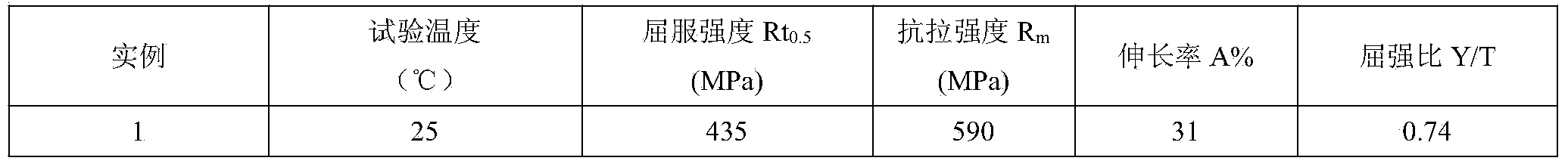

example 1

[0016] Size: 273.1×12.70mm

[0017] chemical composition

[0018] example

C

Si

mn

P

S

Ni

Cr

Mo

Cu

Al

V

Nb

Ti

B

1

0.04

0.20

1.87

0.010

0.006

0.17

0.09

0.09

0.03

0.012

0.005

0.11

0.002

0.00020

[0019] 1) After passing the inspection, the cut-to-length continuous casting slab is heated in the annular heating furnace, and the temperature of the heating furnace is controlled at 1280°C;

[0020] 2) The heated continuous casting round tube billet or round steel ingot raw material is cross-rolled and pierced by a cross-rolling piercer, and the solid hot raw material is pierced into a tubular capillary. The piercing temperature is controlled at 124°C, and the piercing deformation is 3;

[0021] 3) After the perforation, the capillary is then continuously rolled by the MPM continuous rolling mill, the continuous rolling temperature is controlled at 108...

example 2

[0028] Size: 168.3×10.0mm

[0029] chemical composition

[0030] example

C

Si

mn

P

S

Ni

Cr

Mo

Cu

Al

V

Nb

Ti

B

2

0.11

0.21

1.42

0.010

0.007

0.18

0.09

0.08

0.03

0.010

0.05

0.03

0.003

0.00015

[0031] 1) After passing the inspection, the cut-to-length continuous casting slab is heated in the annular heating furnace, and the temperature of the heating furnace is controlled at 1260°C;

[0032] 2) The heated continuous casting round tube billet or round steel ingot raw material is cross-rolled and pierced by a cross-rolling piercer, and the solid hot raw material is pierced into a tubular capillary. The piercing temperature is controlled at 122°C, and the piercing deformation is 3;

[0033] 3) After piercing, the capillary tube is then continuously rolled by the MPM continuous rolling mill. The continuous rolling temperature is controlled at 1050°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com