Multistage pressure-bearing type penetrating sealing method and device

A hole sealing device and permeable technology, which is used in earth-moving drilling, sealing/sealing, wellbore/well components, etc., can solve the leakage gap between the bag and the sidewall of the borehole, low strength, unable to support the grouting pressure and other problems, to achieve the effect of promoting comprehensive mining and utilization, enhancing the degree of penetration, and shortening the time to reach the standard of extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A multi-stage pressure-bearing permeable hole sealing method, specifically comprising the following steps:

[0023] 1) Multi-stage expansion sealing is carried out at the position to be plugged in the drilled hole. The number of expansion sealing sections is not less than four sections, and a permeable sealing section is left between adjacent expansion sealing sections;

[0024] 2) Carry out multi-stage interval grouting for the seepage sealing section, and leave a seepage sealing section for the next level of grouting between the seepage sealing sections of the previous level of grouting; after the completion of the previous level of grouting, Then carry out the next level of grouting; the pressure of the next level of grouting is greater than the pressure of the previous level of grouting;

[0025] 3) When the grouting pressure of the permeable sealing section of the final stage of grouting reaches the predetermined value, the sealing is completed.

[0026] As a pref...

Embodiment 2

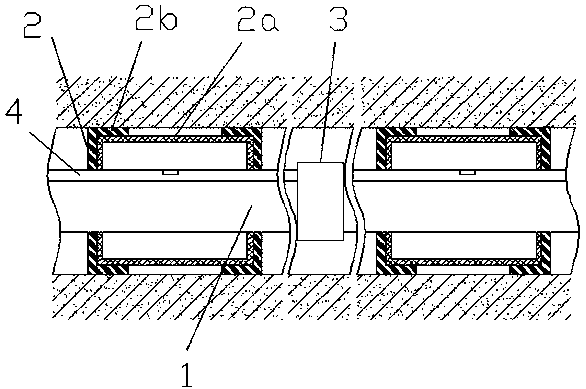

[0029] Such as figure 1 As shown, a multi-stage pressure-bearing permeable hole sealing device includes two bladders 2 sleeved on the main body 1, and the distance between the two bladders is determined according to the length of the sealing section; the main body 1 is provided with a grouting pipe 4 connected with each bladder, and the grouting tube 4 is provided with a blast valve 3 between the two bladders; the bladder 2 includes a sealing section at both ends and a permeation section in the middle. The pouch 2 includes a permeable bag body 2a located in the inner layer, and the two ends of the permeable bag body 2a are covered with a sealing layer 2b, the part covered by the sealing layer 2b is the sealing section, and the uncovered part is the permeable section. According to the actual use effect, the total length of the pouch 2 is preferably 0.8-1.2m, and the length of the permeable section located in the middle is preferably 0.3-0.5m.

[0030] When in use, grout is inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com