Fully-automatic test method for long-time deformation of nonmetal anti-floating anchor rod

A technology of anti-floating anchor rod and test method, which is applied in the test of basic structure, construction, and basic structure engineering, etc., can solve the problem that the accuracy needs to be studied, achieve convenient testing, simple process, and compensate for manual loading and manual reading. insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

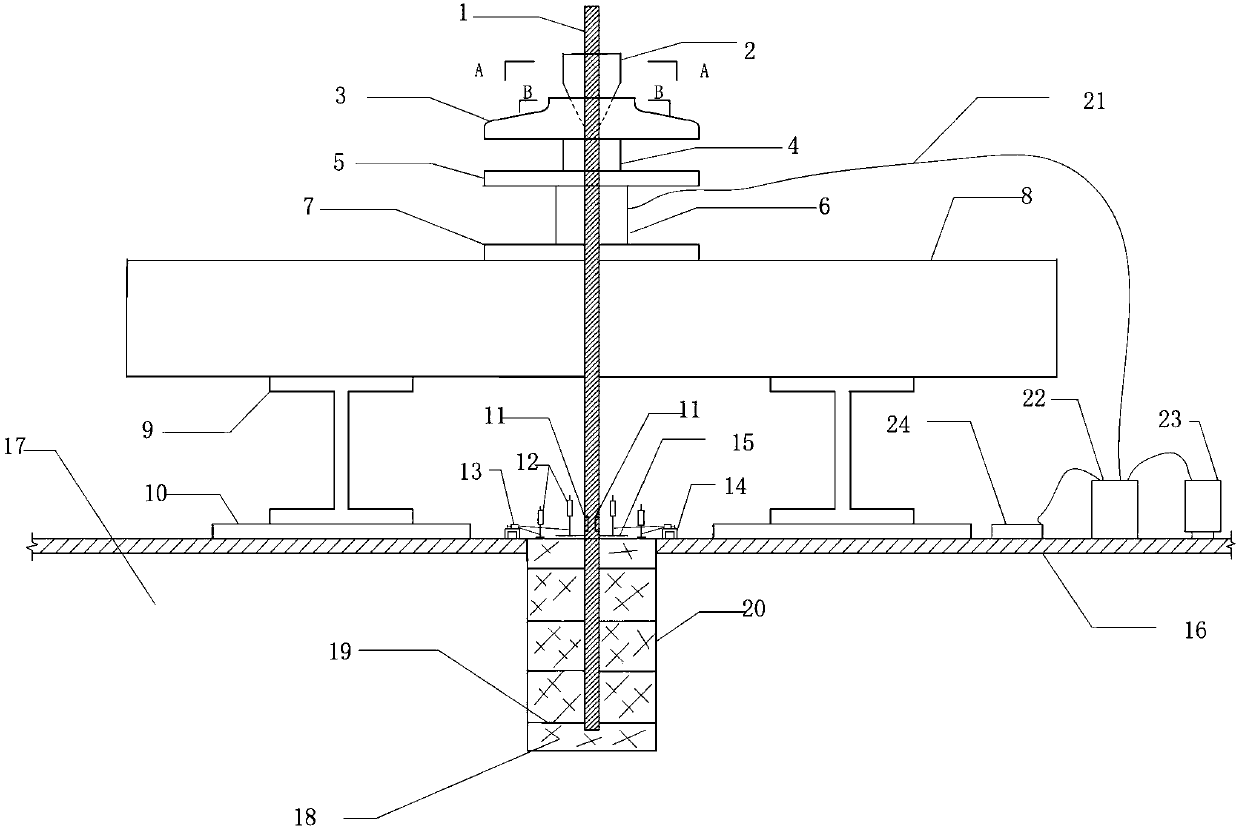

[0022] This embodiment is realized by a metal anti-floating bolt long-term deformation automatic test device, and the specific process is as follows:

[0023] (2) according to the size of anchor rod body 1, carry out drilling to form anchor rod hole 20 at measured rock foundation, and anchor rod hole 20 is perpendicular to ground;

[0024] (2) First install the centering brackets 19 on the outer surface of the anchor rod body 1 at intervals, and the distance between adjacent centering brackets 19 is determined according to the length of the anchorage section of the anchor rod; Insert into the anchor hole 20 until the bottom of the anchor body 1 reaches the bottom of the anchor hole 20, and keep the anchor body 1 vertical during installation;

[0025] (3) Connect the grouting pipe to the outer end of the anchor rod hole 20, and extend the grouting pipe to the bottom of the anchor rod hole 20, and inject the grout along the grouting pipe with the grouting pump. During the grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com