High-rise deviation-rectifying static pressure anchor rod pile and broken pile underpinning supporting device and monitoring method thereof

A technology of supporting devices and anchor piles, applied in the test of foundation structure, repair of foundation structure, construction, etc., can solve the problems of inability to effectively control the structural safety state of high-rise buildings, poor structural safety, high accident rate, etc. To achieve the effect of avoiding excessive deviation correction and sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

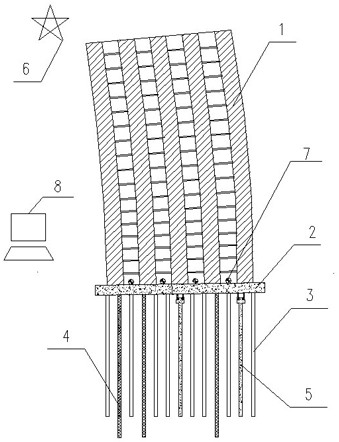

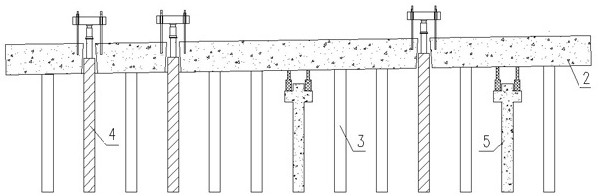

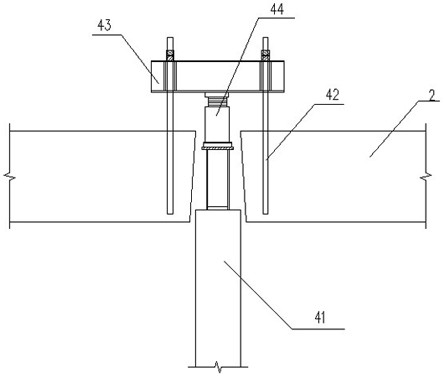

[0049] This embodiment is a kind of high-rise deflection correcting static pressure anchor pile and broken pile underpinning support device, such as Figure 1 to Figure 8 As shown, including the original inclined high-rise building 1, basement floor structure 2, original pile foundation 3, static pressure anchor pile reinforcement structure 4, broken pile underpinning jack structure 5, GPS automatic deviation correction displacement monitoring system 6, structural stress and strain The monitoring network system 7 and the real-time monitoring system 8 of the broken pile underpinning rectification construction are characterized in that: the original pile foundation 3 is arranged under the basement floor structure 2 of the inclined high-rise building 1, and the settlement displacement of the inclined high-rise building 1 is relatively large. On one side, a large number of static pressure bolt pile reinforcement structures 4 are arranged, and a small amount of static pressure bolt ...

Embodiment 2

[0054] This embodiment is the construction monitoring method of the high-rise deflection correcting static pressure anchor pile and broken pile underpinning support device described in Embodiment 1, including the following steps:

[0055] Step 1: Investigate data, use classical total station and theodolite and other measuring instruments to initially measure the tilt displacement state of the inclined high-rise building 1, and use the stress release method to detect the initial stress state of the vertical components of the inclined high-rise building 1 and the basement floor , form the file of the initial state of the inclined high-rise building 1;

[0056] Step 2: on the roof of nearby high-rise buildings, install GPS base station 61, arrange displacement measuring points 62 around the outside of the top of the building, the bottom of the building and the middle position of the building in the inclined high-rise building 1; form a GPS automatic deviation correction displaceme...

Embodiment 3

[0074] This embodiment is a real-time monitoring method for the axial force value of the vertical component of the building deviation correction project. The sensor system monitors the change of the vertical axial force of the vertical structure in the process of building deviation correction in real time, and then adjusts the deviation correction construction process and method in real time. . The sensing system includes vibrating wire strain gauges installed on the vertical components of the building to be corrected, a strain tester for monitoring and recording the strain information of each string strain gauge, and a computer system for collecting the strain information of each string strain gauge , and a civil engineering smart monitoring cloud platform system installed on a computer. The vibrating wire strain gauge monitors the real-time axial force value on the vertical member of the building during the rectification construction process in real time, and after being mon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com