Semi-assembled bamboo plywood-steel pipe dust collection mountain flour concrete combined column and manufacturing method thereof

A technology of concrete columns and manufacturing methods, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of consuming manpower, material resources and land resources, and difficult to use, so as to improve the failure mode of force, low manufacturing cost, and reliable integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

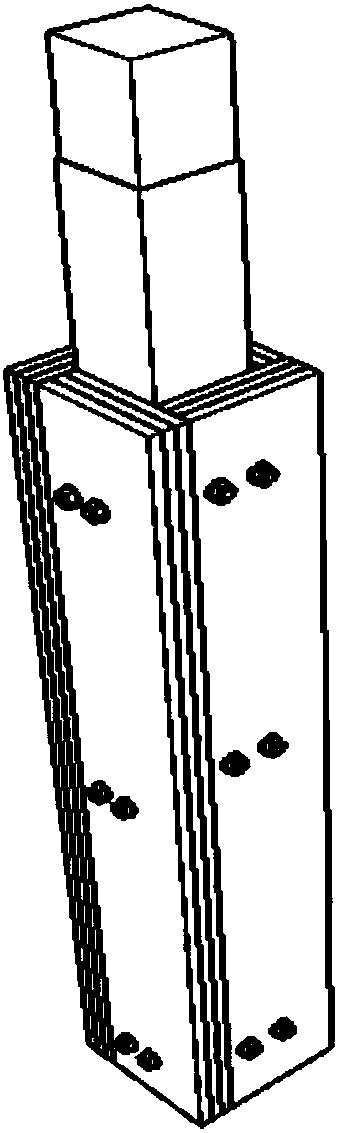

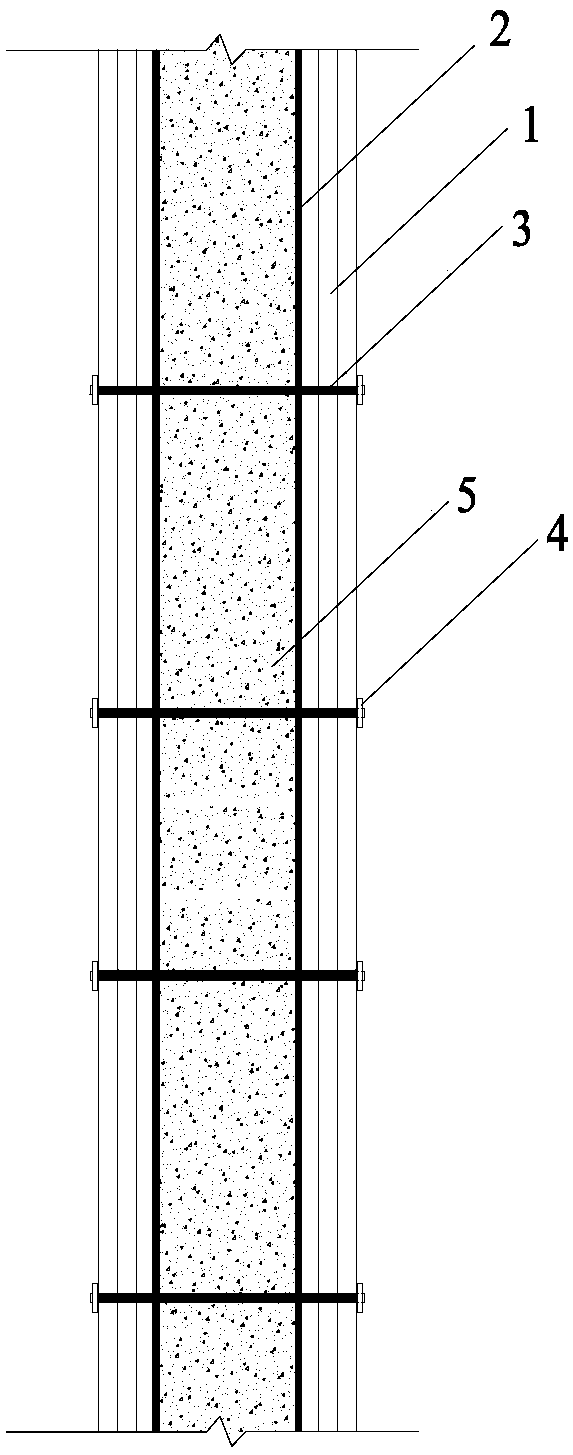

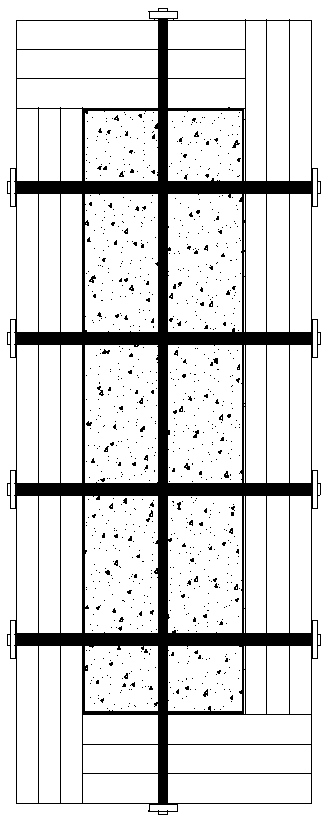

[0036] A semi-assembled bamboo plywood-steel pipe dust-collecting stone powder concrete composite column comprises: a bamboo plywood layer, a steel pipe, a dust-collecting stone powder concrete column, several threaded steel tie rods and several nuts. The dust-collecting stone powder concrete column is located inside the steel pipe, and the bamboo plywood layer is pasted on the outer wall of the steel pipe, and the glued surface between the bamboo plywood layer and the outer wall of the steel pipe is coated with epoxy resin adhesive glue. The dust-collecting stone powder concrete is low-strength concrete mixed with dust-collecting stone powder cement and prepared according to a certain concrete ratio; the steel tie rod is a straight rod with a diameter of 6mm. The two ends of the steel tie rod are threaded, and the steel tie rod is in the form of a cross. It is arranged vertically to the axial direction of the steel pipe, and both ends of the steel tie rod are provided with nut...

Embodiment 2

[0048] Such as Figure 4 As shown, in this embodiment, the cross-section of the combined column is L-shaped, and the joining method of the bamboo plywood is positive joint.

[0049] Parts not mentioned in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0051] Such as Figure 5 As shown, in this embodiment, the cross-section of the combined column is T-shaped, and the joining method of the bamboo plywood is snap joint.

[0052] Parts not mentioned in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com