Rubber powder-asphalt emulsion for concrete asphalt mortar and method for producing the same

A technology of cement asphalt and asphalt emulsion, which is applied in building components, building insulation materials, construction, etc., can solve the problems of reducing the cost of rubber powder consumption of asphalt, and achieving the effect of improving stability and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

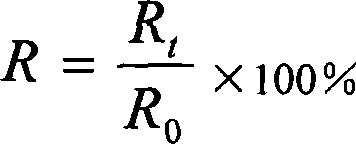

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited only to the following examples, wherein Table 1 is the mixing ratio of the examples, and Table 2 has provided the adopted examples. The type of raw material, table 3 has provided the preparation method that each embodiment adopts.

[0031] Table 1 Example mix ratio

[0032]

serial number

Mixing ratio (mass percentage)

asphalt

rubber powder

water

Emulsifier

stabilizer

thickener

Auxiliary for pH

Comparative example 1

60

0

37.9

1.5

0.3

0.2

0.1

Example 1

50

10

37.9

1.5

0.3

0.2

0.1

Example 2

40

20

37.9

1.5

0.3

0.2

0.0

Example 3

30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com