Magneto-rheological clutch, brake and variable speed control drive assembly device

A magneto-rheological and magnetorheological fluid technology, which is applied to fluid transmission devices, transmission devices, fluid clutches, etc., can solve problems such as optimization combination of difficult-to-separate devices, low degree of automation control, difficult product technology upgrades, etc., to achieve control Social production costs, solving automation functions, and solving the effects of various varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

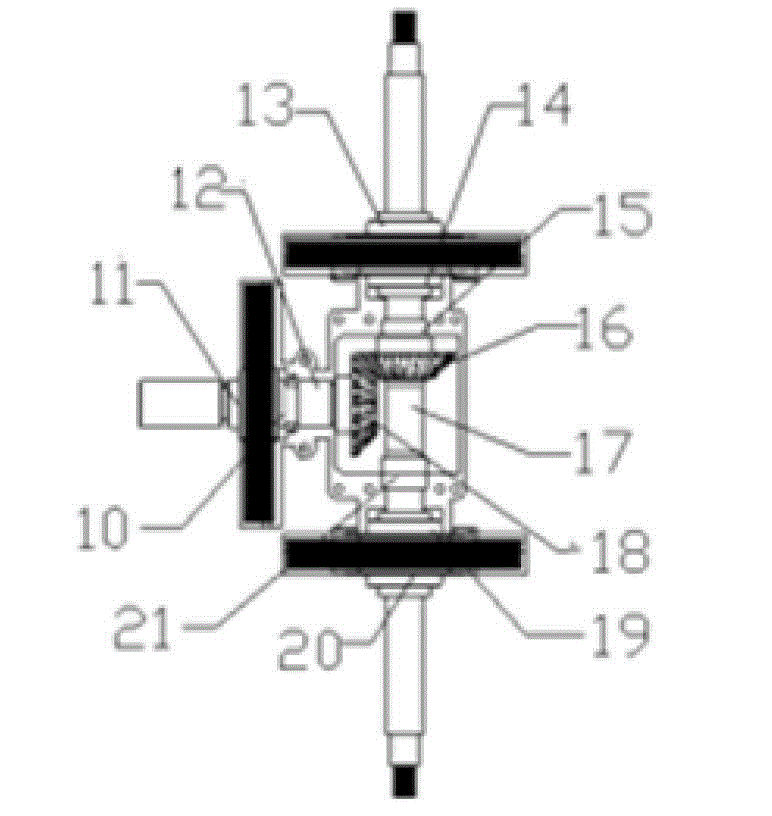

[0034] The invention innovatively integrates the three functional mechanisms of the clutch, brake and transmission into a drive box assembly component unit, and takes the lead in applying magnetorheological technology to the field of power control of small and medium-sized vehicles, and solves the problem of using magnetorheological fluid As a power transmission medium, it realizes the operation, control and management of the clutch, brake and speed change of the vehicle power.

[0035] 1. Process procedure

[0036] 1. First prepare the parts and magnetorheological fluid materials produced according to the attached drawings.

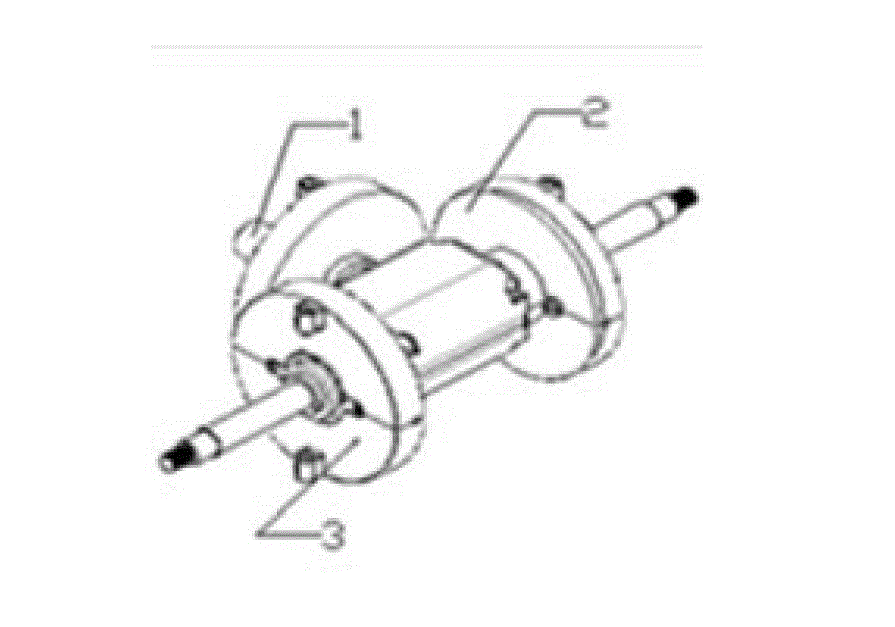

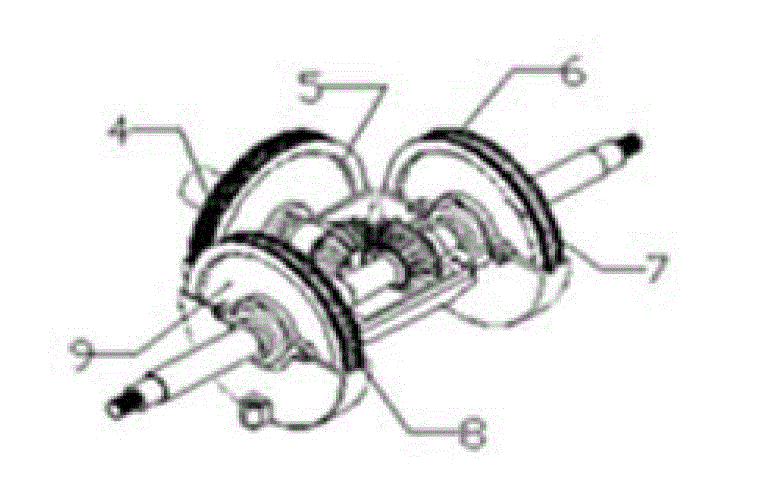

[0037]Specifically, it includes a shaft coupling 1, an upper housing 2, a lower housing 3, a clutch coil 4, a clutch housing 5, a brake coil, a brake housing, a clutch frame shaft 10, a clutch disc shaft 11, a clutch bearing 12, Brake disc frame, reversing bearing, reversing gear 16, reversing shaft 17 and power gear 18, described shaft coupling 1, clut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com