Vacuum aluminium coating laser bidirection drawed BOPP film and its production method

A technology of polypropylene base film and biaxial stretching, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of high cost of raw materials and production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

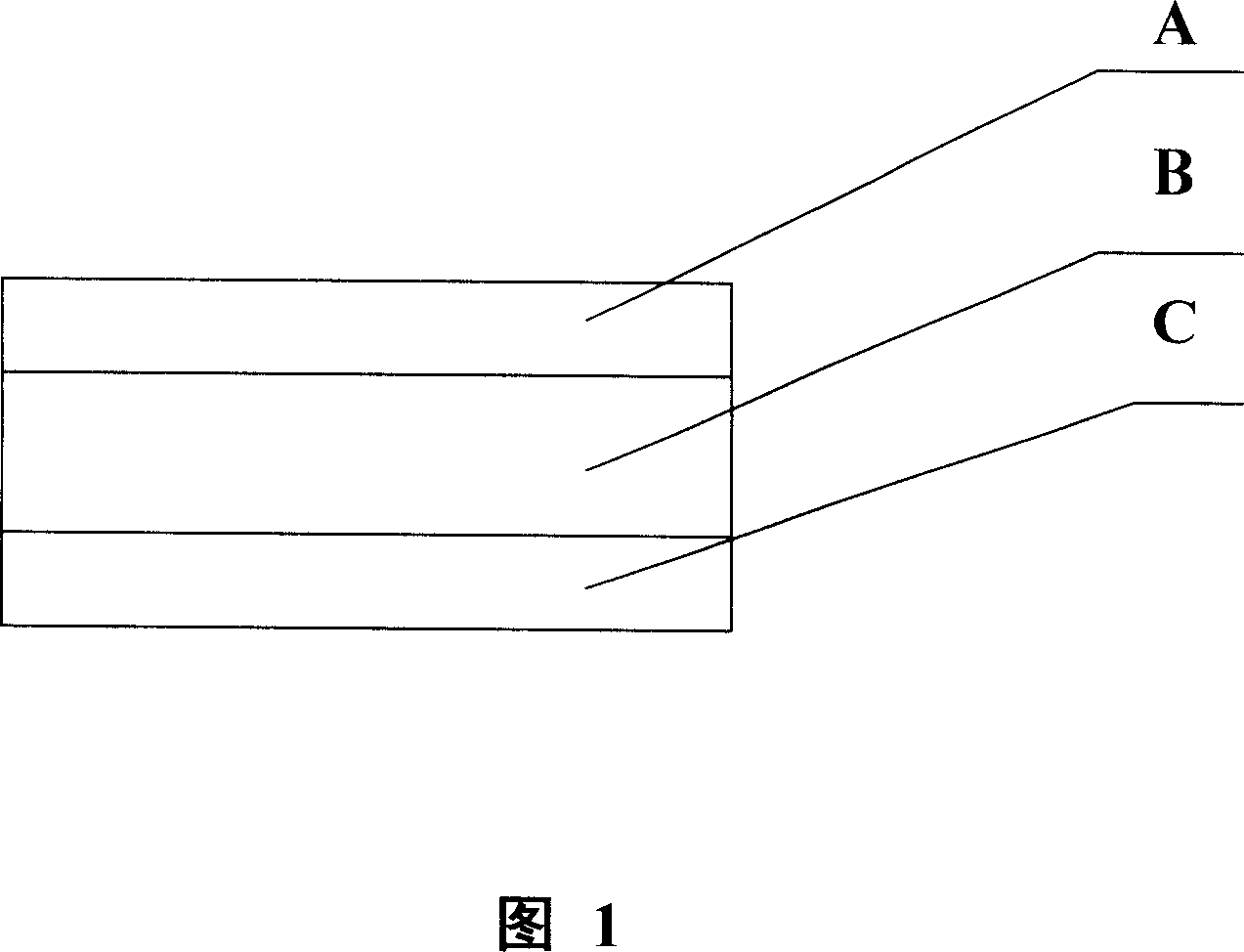

[0035] Embodiment one: by above-mentioned technology, raw material, auxiliary material are pressed,

[0036] In upper surface layer A: Homopolypropylene 97%

[0037] Anti-sticking agent 3%

[0038] In core layer B: Homopolypropylene 98%

[0039] Antistatic agent 2%

[0040] In the lower surface layer C: Homopolypropylene 97%

[0041] Anti-sticking agent 3%

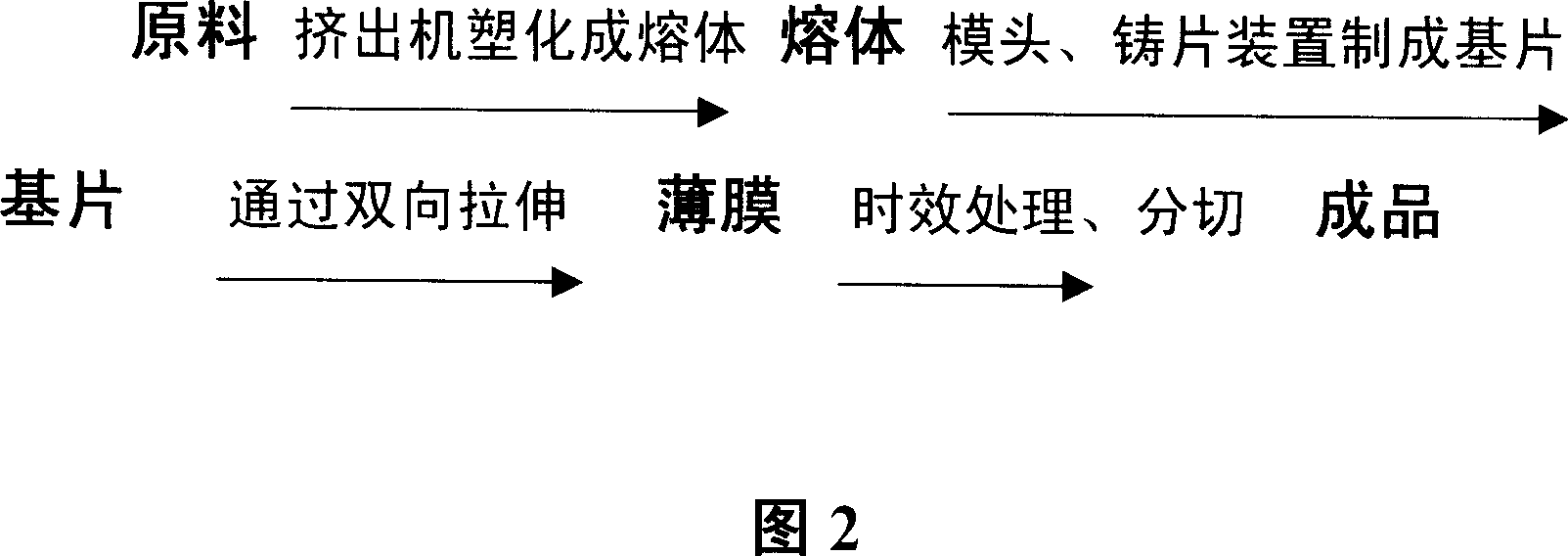

[0042] Mix the selected raw and auxiliary materials separately and mix evenly, then send the uniformly mixed raw and auxiliary materials into the extruder to be plasticized into a melt, and the melt is co-extruded through the pipe through the die casting device to form a thick After the thick sheet is stretched longitudinally and transversely by a polypropylene biaxial stretching machine, the thick film is stretched longitudinally and transversely by a biaxial stretching machine to form a film. The thickness of the film is adjusted by an automatic thickness measuring device to reach...

Embodiment 2

[0043] Embodiment two: the raw and auxiliary materials are pressed,

[0044] In upper surface layer A: Homopolypropylene 96%

[0045] Anti-sticking agent 4%

[0046] In core layer B: Homopolypropylene 97%

[0047] Antistatic agent 3%

[0048] In the lower surface layer C: Homopolypropylene 96%

[0049] Anti-sticking agent 4%

[0050] The technique of this embodiment is the same as embodiment one. The base film product produced according to this scheme is suitable for the processing of laser transfer products after pre-coating vacuum aluminum plating.

Embodiment 3

[0051] Embodiment three: raw and auxiliary materials are pressed:

[0052] In upper surface layer A: Homopolypropylene 95%,

[0053] Anti-sticking agent 5%

[0054] In core layer B: Homopolypropylene 96%

[0055] Antistatic agent 4%

[0056] In the lower surface layer C: Homopolypropylene 95%

[0057] Anti-sticking agent 5%

[0058] The technique of this embodiment is the same as embodiment one. The base film product produced according to this scheme is not only suitable for the processing of pre-coated vacuum aluminum-coated products for general purposes, but also can be embossed with strong local or overall layering after pre-coated vacuum aluminum-plating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com