Pyrophyllite-based composite titanium white powder and preparation method thereof

A technology of composite titanium dioxide and rutile titanium dioxide, which is applied in the field of powder pigments, can solve the problems of high power consumption, high equipment investment cost, pollution, etc., and achieve the effects of increasing production, reducing investment cost, and good hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

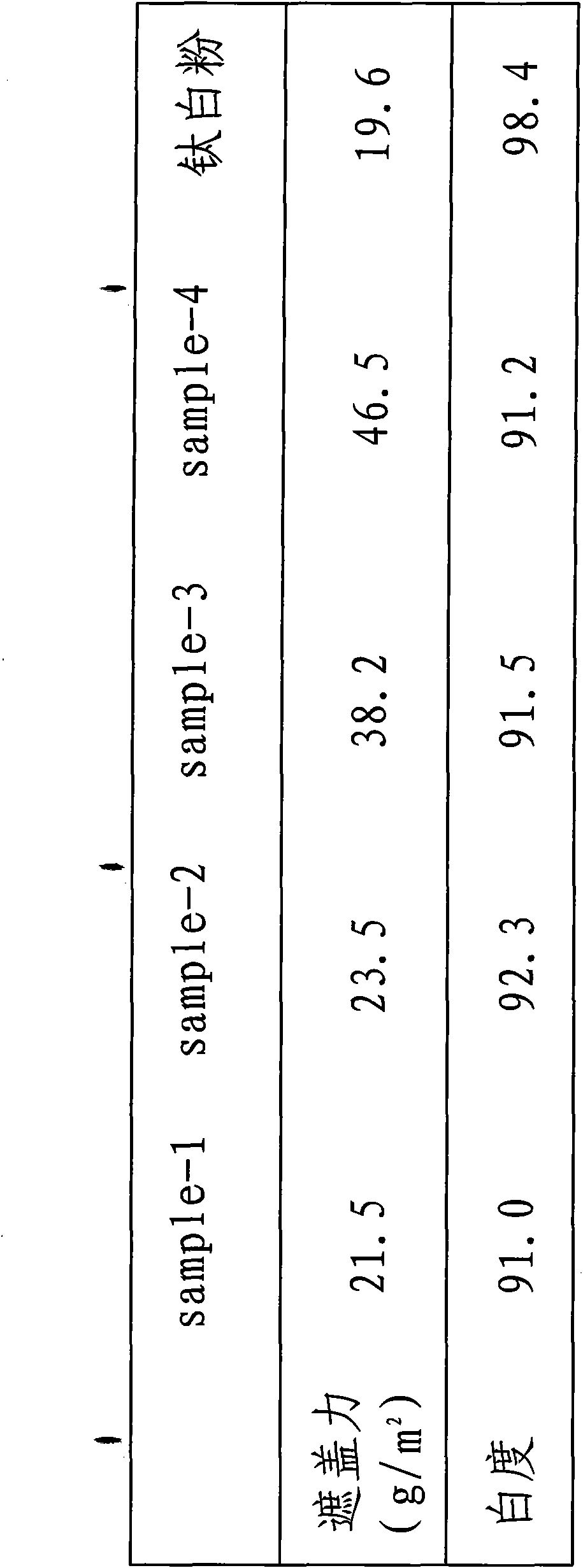

[0024] A pyrophyllite-based composite titanium dioxide, including pyrophyllite and rutile titanium dioxide, the mass ratio of pyrophyllite to rutile titanium dioxide is 50-90:50-10, and the blue-white luminosity of pyrophyllite is 75 -84, pyrophyllite powder is 100-2000 mesh.

[0025] In the embodiment of the present invention, a modifying agent for modifying the surface of pyrophyllite can also be added, the modifying agent can be sodium stearate, or stearic acid, sodium stearate and pyrophyllite and The mass ratio of rutile titanium dioxide is 50-90:50-10:0.5-2.5, and the mass ratio of stearic acid to pyrophyllite and rutile titanium dioxide is also 50-90:50-10:0.5-2.5. And the concentrations of stearic acid and sodium stearate are both 0.5%-2.5%.

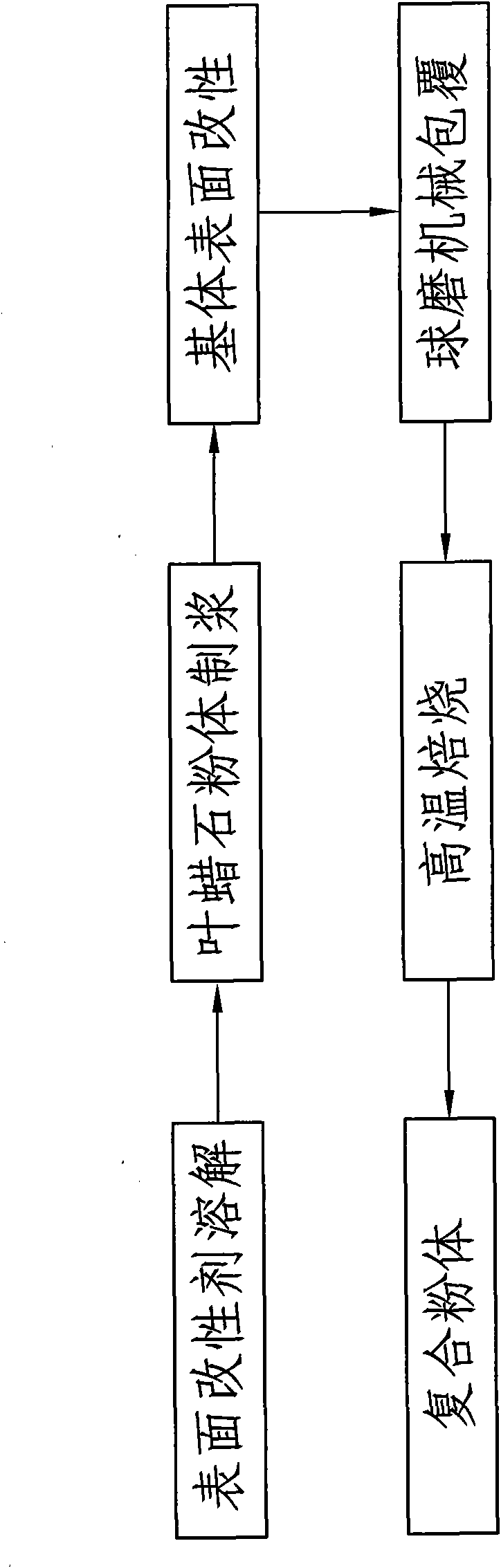

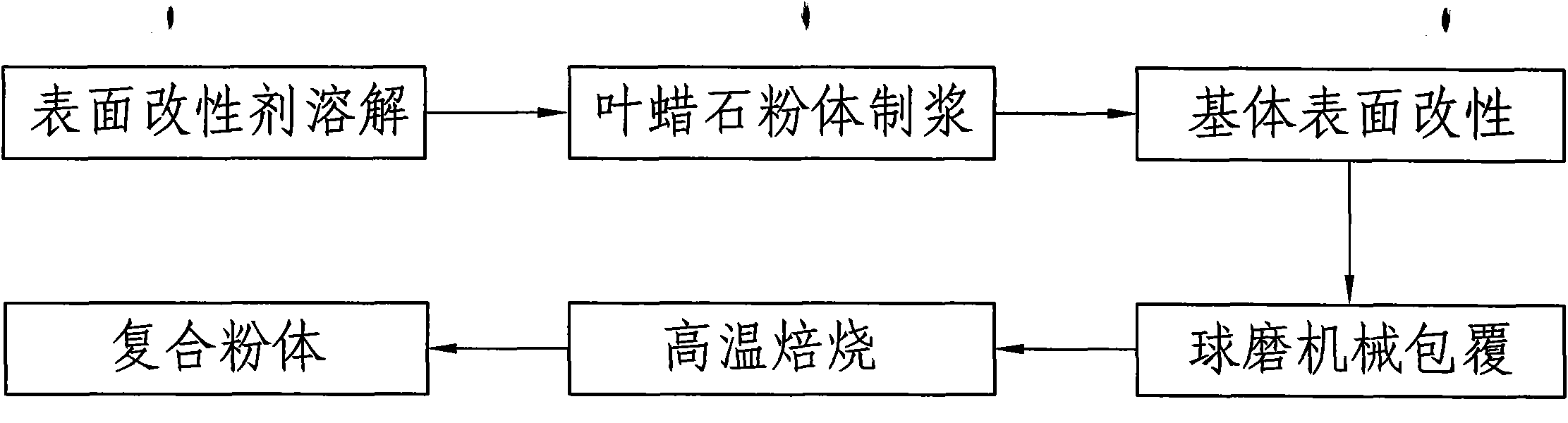

[0026] like figure 2 Shown preparation method of the present invention, concrete steps are as follows:

[0027] 1) pulping: making the pyrophyllite into a slurry with a concentration of 15%-35%;

[0028] 2) mixing: mixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com