Lay-up arrangement and structural arrangement and method for producing a component for aerospace

A structural and structural technology, applied in the field of laminated structures, can solve problems such as time-consuming, high production costs, and positioning errors, and achieve the effects of easy positioning accuracy, cost savings, and cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

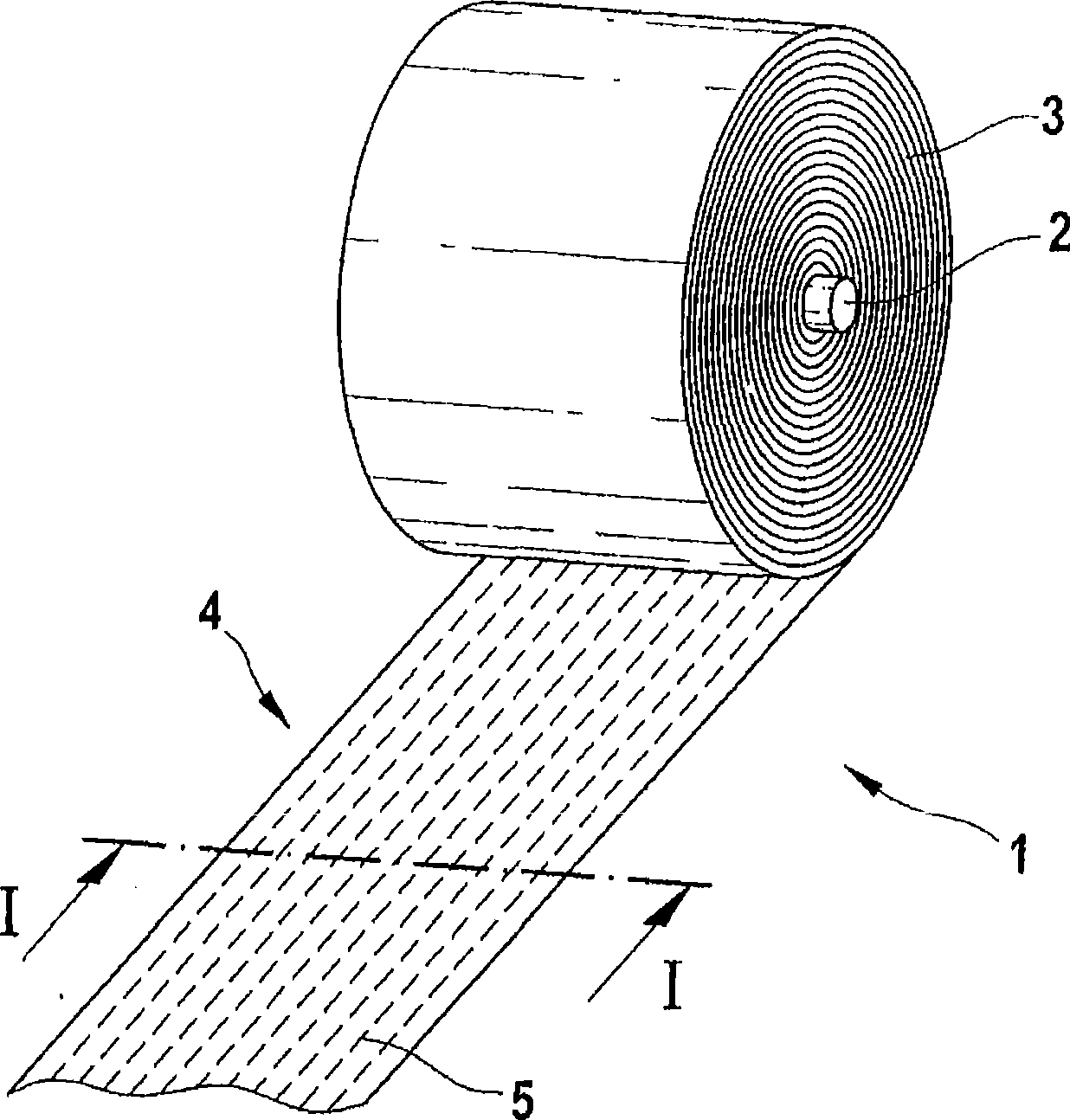

[0041] figure 1 The laminated structure 1 according to the first exemplary embodiment of the present invention is shown in a perspective view.

[0042] The laminated structure 1 is provided in the form of a bundle 3 coiled around a mandrel 2 . The fabric-like end that has been unfolded is indicated with reference numeral 4 . The broken lines schematically show the fiber directions of the glass fibers 5 in the laminated structure 1 . Preferably, the glass fibers 5 extend in the unfolding direction, ie along the fabric-like end 4 .

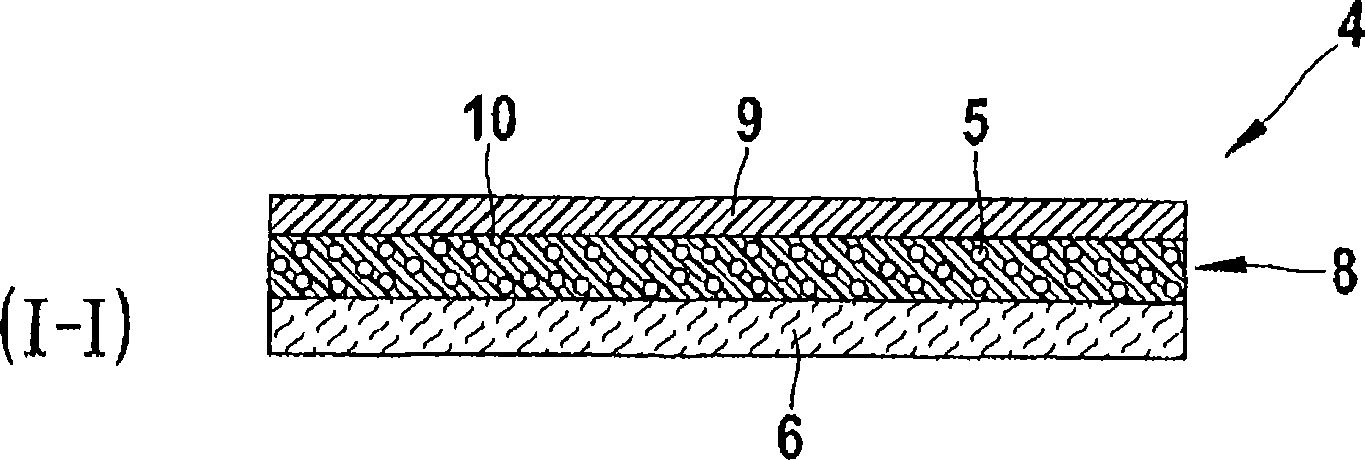

[0043] figure 2 display edge figure 1 Sectional view of the section line I-I in.

[0044] Preferably, the laminated structure 1 comprises a backing layer 6 , a glass fiber laminate 8 and a protective film 9 . Preferably, the backing layer 6 is designed in the form of a paper layer. Arranged on top of the backing layer is a glass fiber layer 5 extending perpendicular to the cross-sectional plane. Located between the glass fibers 5 is a resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com