Electrostatic suction-type fluid discharging method and device

An electrostatic attraction and discharge device technology, which is applied to the surface coating liquid device, coating, printing, etc., can solve the problem of not taking into account the miniaturization of the nozzle and the low voltage of the driving voltage, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

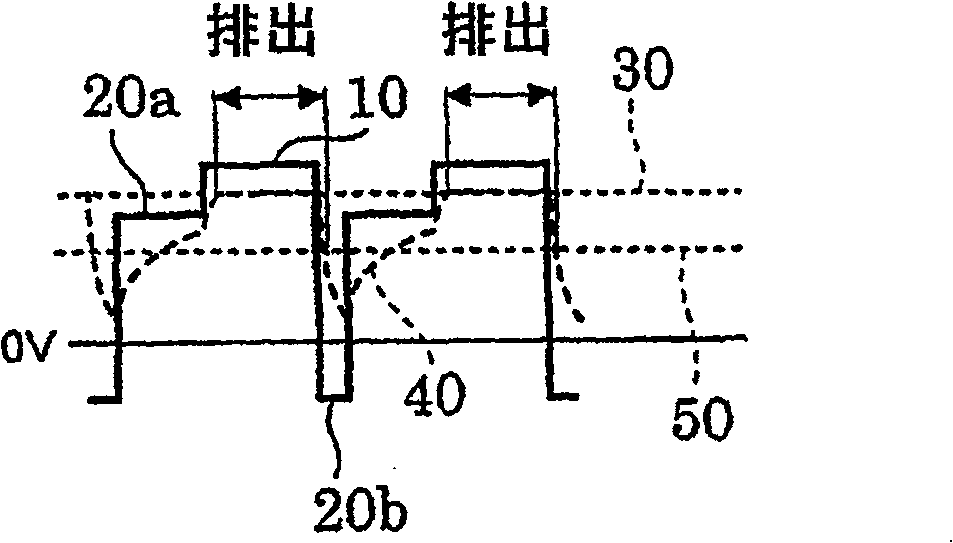

[0152] As described above, in the electrostatic attraction type fluid discharge using the local electric field, both the nozzle and the driving voltage can be made small. In this case, in order to discharge the fluid as a single flow, the method adopted is also to apply a pulse voltage between the nozzle filled with the fluid and the substrate arranged to face the tip of the nozzle, and the liquid is attracted from the tip of the nozzle to the On the substrate side, droplets are formed on the substrate.

[0153] According to this method, if the upper limit voltage (upper limit value) of the pulse voltage applied between the nozzle and the substrate is larger, the amount of fluid discharged from the nozzle will be larger; Fluid volume is low. That is, the discharge amount can be controlled by controlling the upper limit value of the pulse voltage.

[0154] However, in the case of this model, the discharge responsiveness is basically determined by the product of the resistance...

Embodiment approach 2

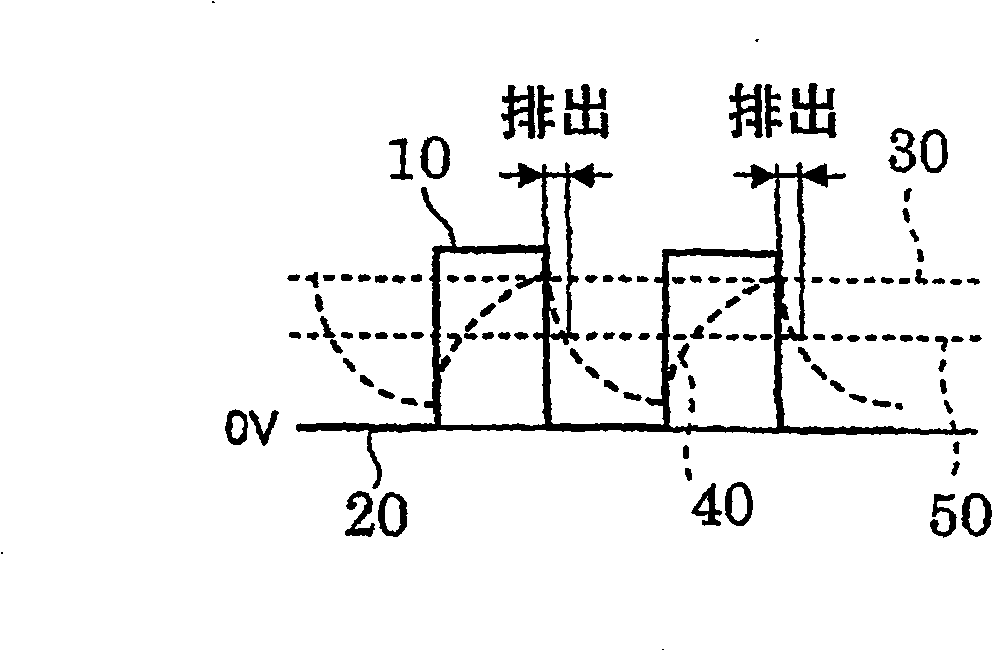

[0245] In the electrostatic attraction type discharge based on the fluid discharge model using a local electric field, as described above, both the nozzle diameter and the drive voltage can be reduced.

[0246] However, when using the fluid discharge model of the local electric field, the discharge responsiveness is basically determined by the time constant of the product of the resistance R of the fluid between the electrode inside the nozzle and the tip of the nozzle and the capacitance C between the tip of the nozzle and the substrate. RC lowered. Furthermore, the cell parameters of the resistance R and the capacitance C include the nozzle diameter d, and the discharge responsiveness changes with the nozzle diameter. As described above, as the nozzle diameter d decreases, the time constant RC becomes extremely large, so that the discharge responsiveness is poor, and the dischargeable polar frequency becomes low.

[0247] That is, in electrostatic attraction type fluid disc...

Embodiment approach 2-1

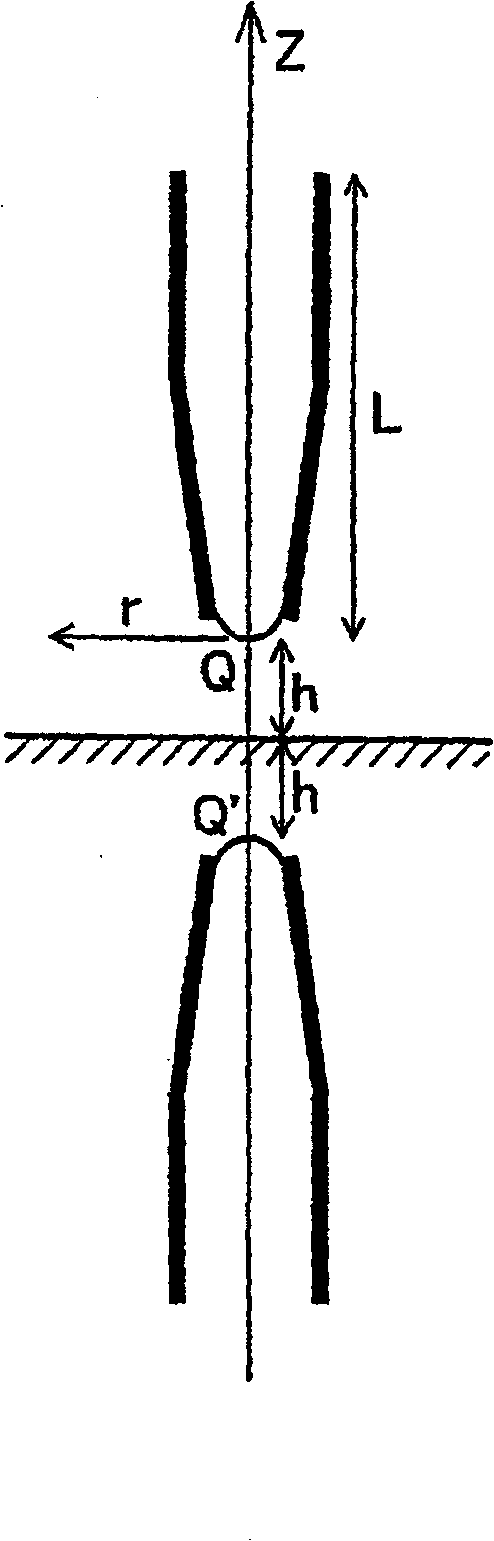

[0252] Figure 18 A side sectional view showing essential parts of the electrostatic attraction type fluid ejection device of this embodiment.

[0253] In such an electrostatic attraction type fluid discharge device, a substrate stage 6 functioning as an address electrode 14 is provided at a predetermined distance away from the nozzle hole of the nozzle 1 on the side facing the nozzle hole, and the substrate 13 is placed on the substrate stage 6. The purpose is to make the discharge material discharged from the nozzle hole of the nozzle 1 hit the surface of the substrate 13 stably.

[0254] Here, the substrate stage 16 is given a function as a counter substrate, but as described above, according to the present invention, due to the electric field concentration effect at the tip of the nozzle and the mirror image force induced on the counter substrate, it does not It is necessary to make the substrate conductive as in the prior art, or to provide a counter electrode on the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com