Gas sensitive material comprising microcrystalline selenium and gas sensor using same

a technology of microcrystalline selenium and gas sensor, which is applied in the field of gas sensor and microcrystalline selenium gas sensor, can solve the problems of lack of room temperature stability, gas sensor, and inability to distinguish the kind of gas with good sensitivity, and achieves simple sensor element structure, high cost advantage, and easy production and economic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

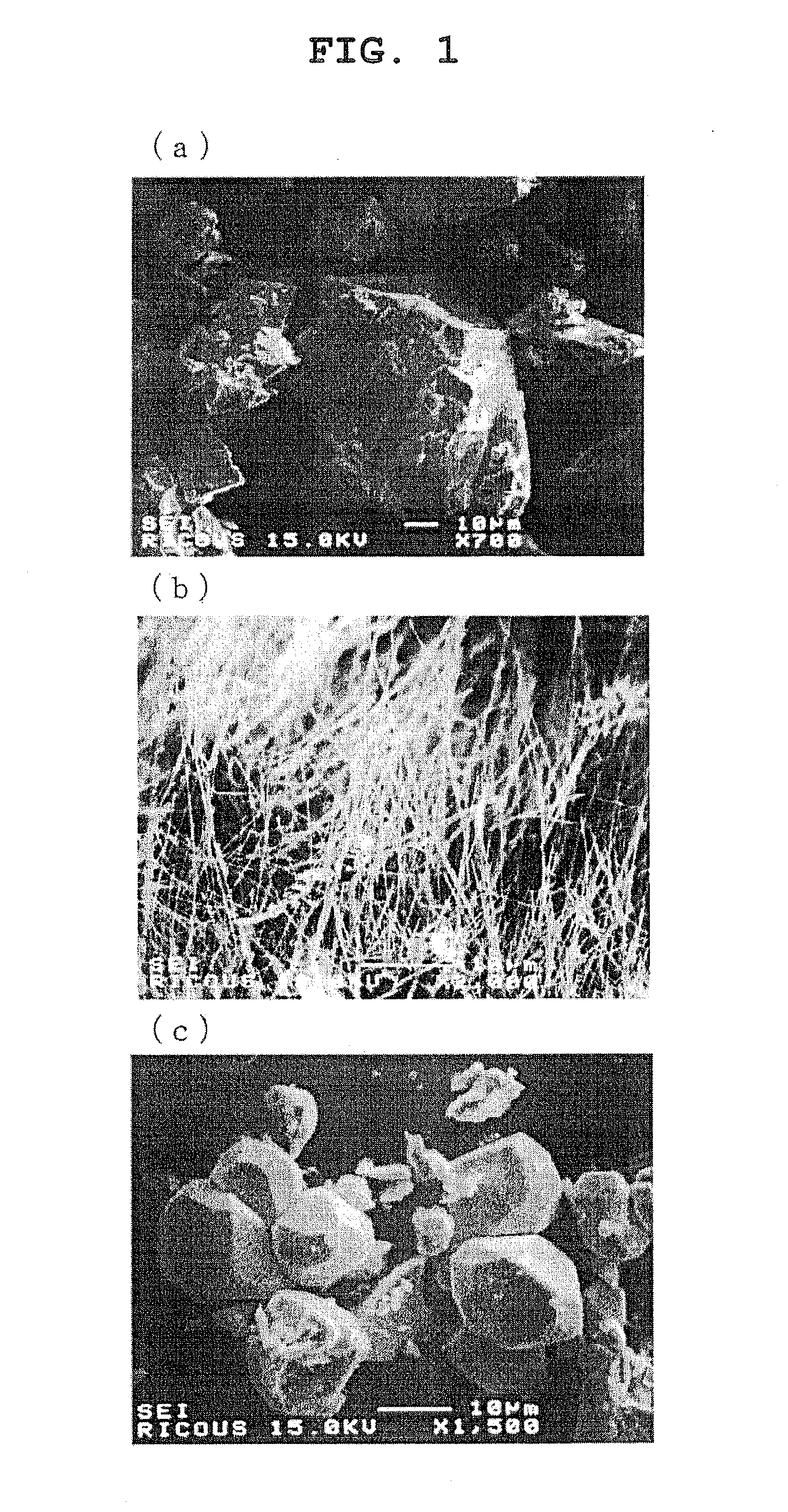

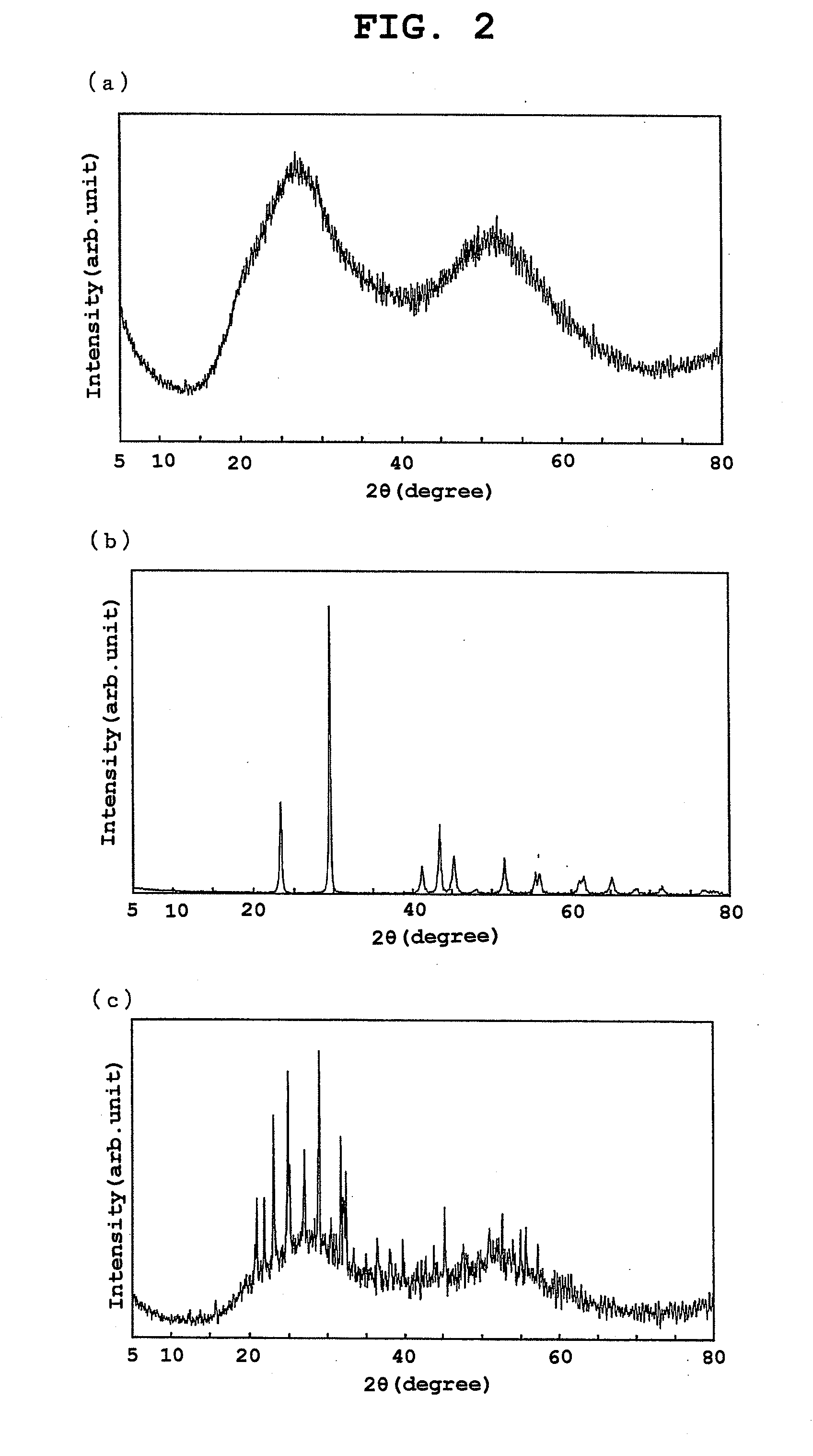

[0086]A commercially available granular amorphous selenium (purity: 99.9999%, Rare Metallic Co., Ltd.) was milled into a fine powder in a mortar. The granulated amorphous selenium was irregular particles having a particle size of 20-30 μm. This amorphous selenium fine powder (about 0.3 g) was added to acetone (7 mL, relative permittivity: 20.7) in a glass tube, and the mixture was left standing at room temperature for 10 days. In addition, similarly, an amorphous selenium fine powder (about 0.3 g) was added to benzene (7 mL, relative permittivity: 2.3) in a glass tube, and the mixture was left standing at room temperature for 10 days.

[0087]The form of the amorphous selenium fine powder, the resultant product in acetone and the resultant product in benzene was observed with a scanning electron microscope (SEM, JOEL JXA-8900). In addition, the crystal structures thereof were analyzed by an X-ray diffraction apparatus (manufactured by Rigaku Corporation, RINT 2500).

[0088]FIG. 1(a) is a...

example 2

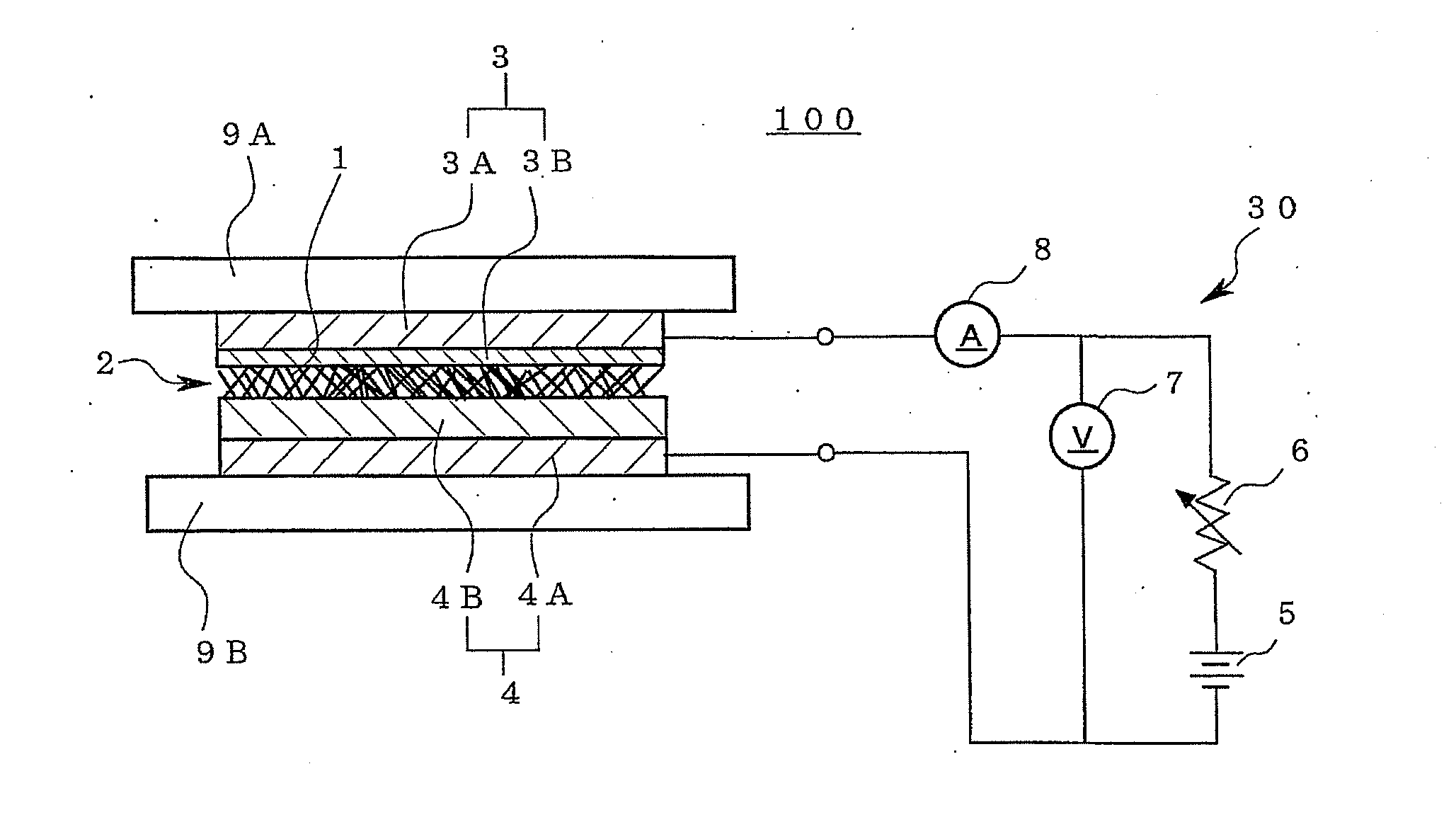

[0091]A gas sensor shown in FIG. 4 was produced using the selenium nanowire (nanowire hexagonal microcrystalline selenium with thickness 258 nm and length 4.3 μm) and granular microcrystalline selenium (granular monoclinic microcrystalline selenium having an average particle size of about 10 μm), which were obtained in Example 1, and the amorphous selenium fine powder (ground product) used in Example 1.

[0092]That is, an ultratrace amount (about 50 μg) of a selenium nanowire was uniformly adsorbed on one surface of a carbon tape (length×width×thickness of 1.0 mm×1.0 mm×0.16 mm, manufactured by Nisshin EM Corporation, carbon double-faced adhesive tape) with a wooden extra fine stick. The thickness of the carbon tape after adsorption of the selenium nanowire was about 75 μm, and that of a selenium nanowire adsorption layer was 23 μm. The selenium nanowire was weighed with Sartorius Basic plus balance BP221S manufactured by SARTORIUS K.K. One surface of the carbon tape, which is on the ...

experimental example 1

[0097]Using the gas sensor apparatus prepared above, an organic gas was contacted with a gas detector part through which an electric current was flown at room temperature and fixed voltage 5V, and current value change (I / I0) due to the organic gas were examined. Here, I0 is a constant current value before contacting the organic gas with the gas detector part, and I is a current value after contacting the organic gas with the gas detector part. As the organic gas, acetone and benzene were used, and the organic gas was contacted with the gas detector part by impregnating a cotton swab with the organic solvent (acetone, benzene), bringing the cotton swab near to the gas detector part, and allowing contact of each gas (acetone 5400 ppm, benzene 220 ppm) volatilized from the cotton swab with the gas detector part for 120 seconds. The concentration of the organic gas was measured by a gas detector tube manufactured by GASTEC CORPORATION. The method including impregnating a cotton swab wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com