Adhesive tape sticking device

A technology for sticking tape and tape, which is applied in the field of tape sticking device, cutting and sticking device, and tape supply field. problem, to achieve the effect of good application prospects, manpower saving, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

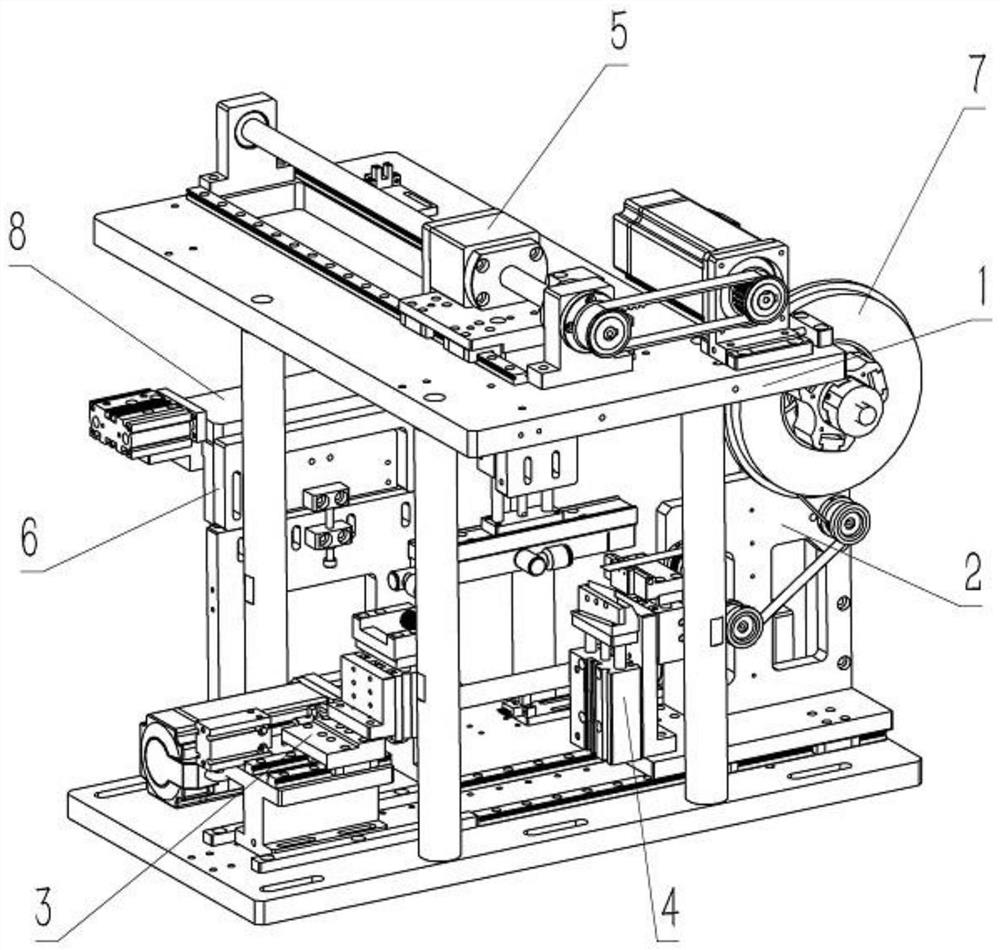

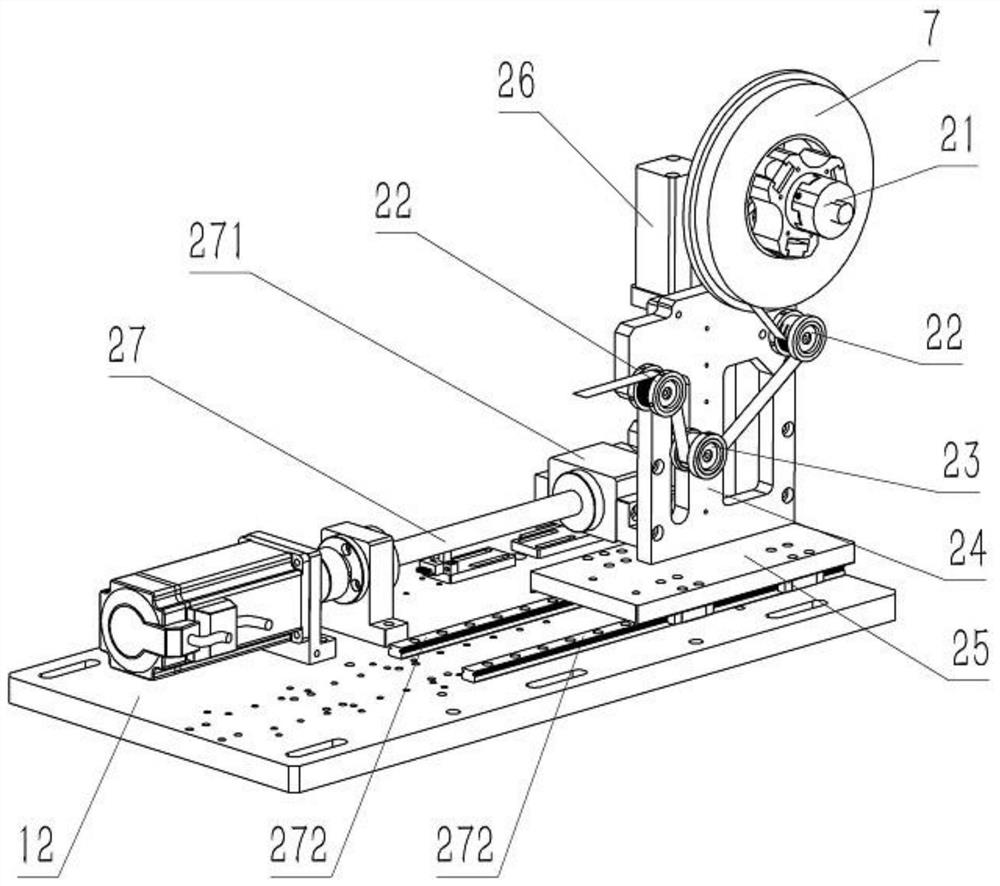

[0043] A tape sticking device, such as figure 1 As shown, it includes a layered support 1, a moving feed mechanism 2, a tape head positioning mechanism 3, a tape positioning and cutting mechanism 4, a tape pressing mechanism 5, and a glued object positioning mechanism 6; the specific structural composition and working process are as follows:

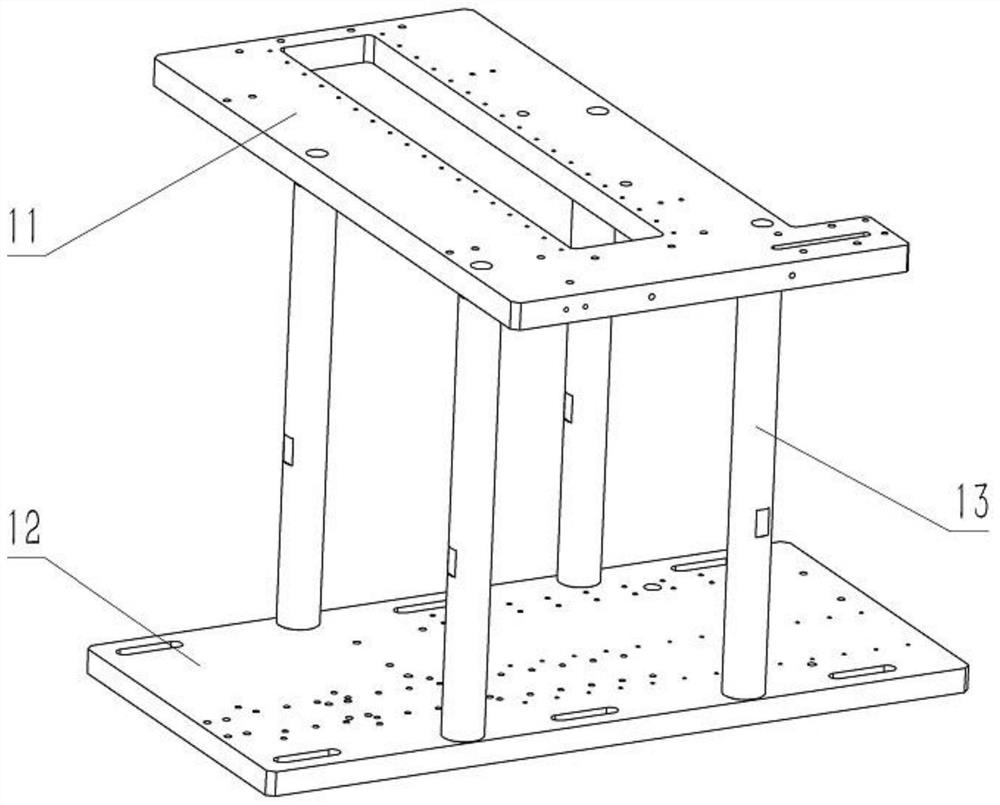

[0044] like figure 1 , figure 2 As shown, the layered support 1 is divided into upper and lower layers, and a moving feed mechanism 2 and a tape head positioning mechanism 3 are installed on the lower panel 12. The tape positioning and cutting mechanism 4 is installed on the moving feed mechanism 2, and moves along The feeding mechanism 2 moves synchronously; the upper layer is used to install the tape pressing mechanism 5, which is separated up and down to effectively save the floor space of the device; the moving feeding mechanism 2 is located on the bottom layer and is used to fix the tape reel 7; the tape head positioning mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com