Labeling machine for producing RFID labels

An RFID label and label machine technology, applied in the field of electronic label production equipment, can solve the problems of manual operation errors, difficult to meet the increasing demand of RFID labels, and low degree of automation, so as to solve the problems of manual operation errors and improve the degree of automation , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

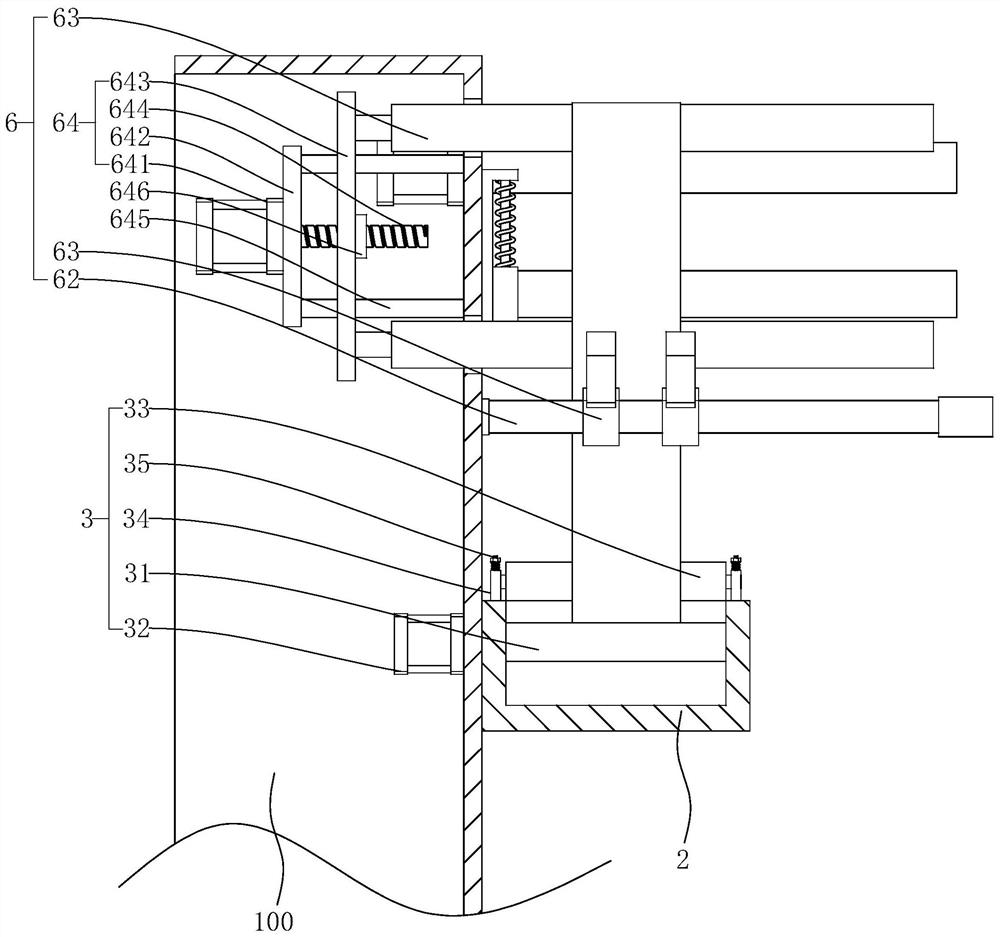

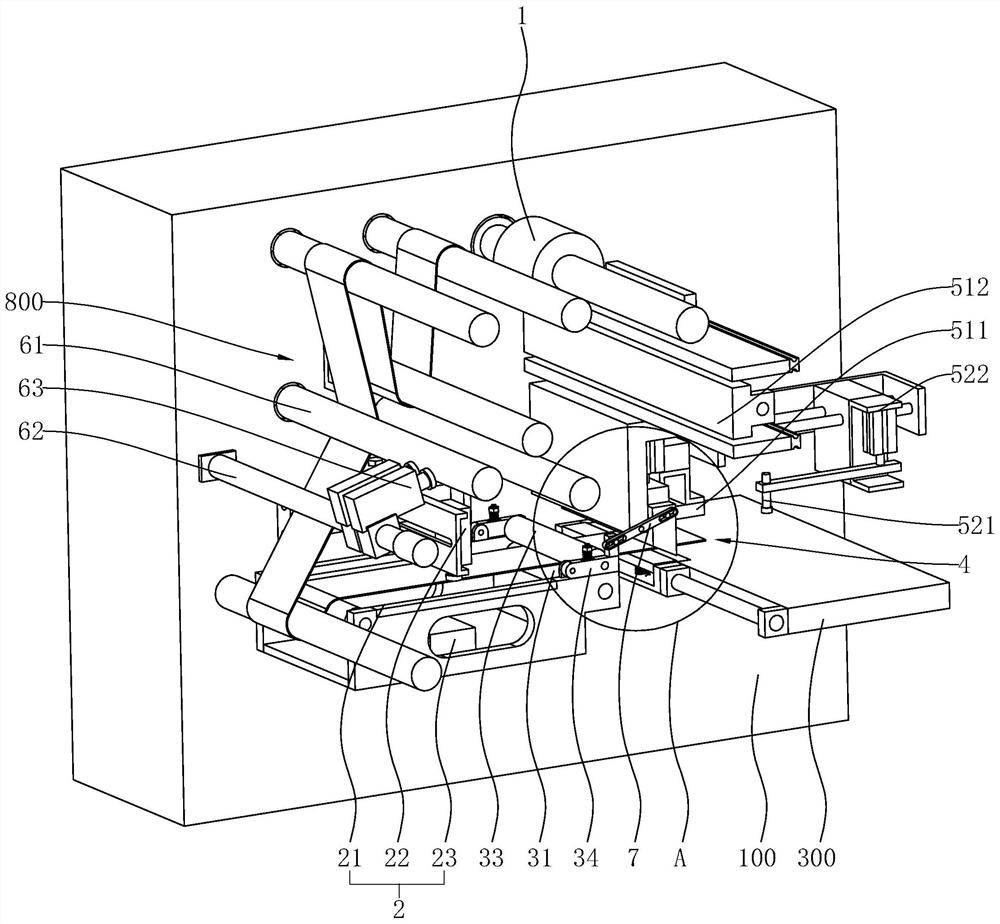

[0031] The following is attached Figure 1-4 The application is described in further detail.

[0032] The embodiment of the present application discloses a labeling machine for producing RFID labels.

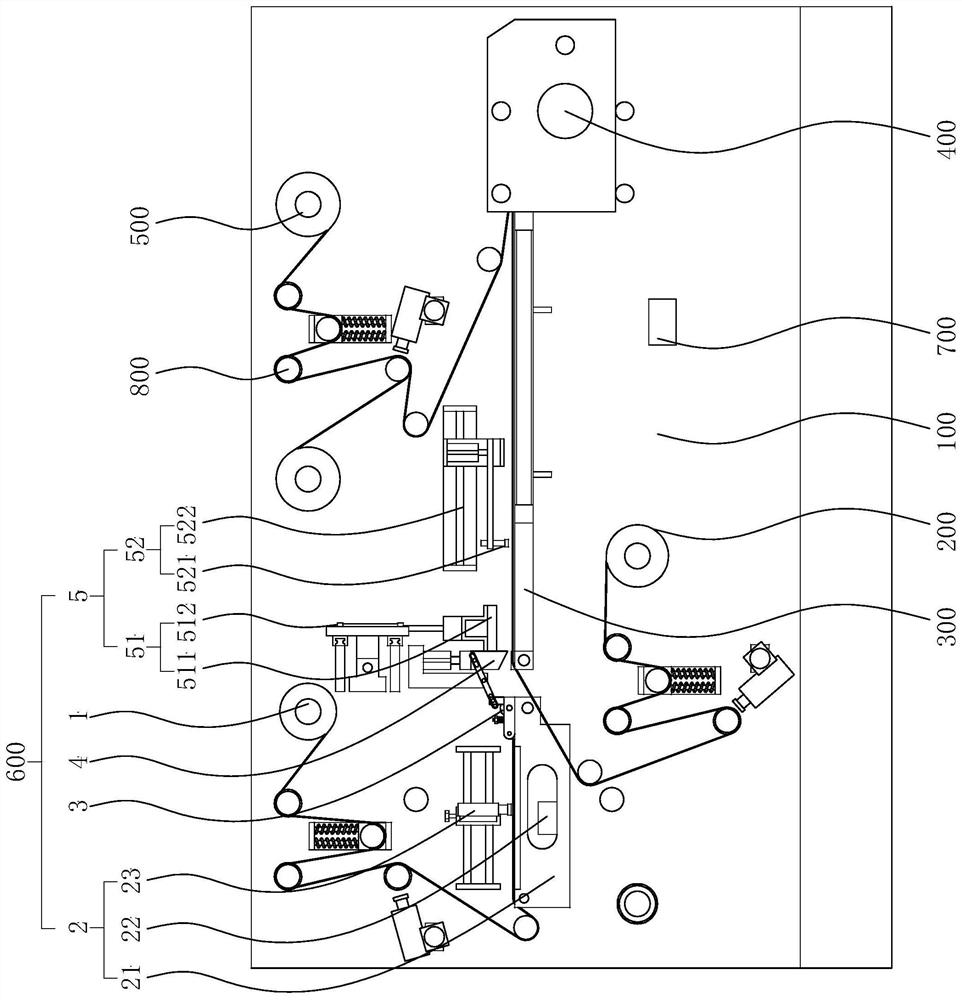

[0033] refer to figure 1 , the label machine for producing RFID labels includes a frame 100, a release paper unwinding device 200, a workbench 300, a composite winding device 400, a face paper unwinding device 500, a chip sticking device 600 and a control module 700, wherein the frame 100 It is a rectangular frame-like structure arranged vertically, and the release paper unwinding device 200, the workbench 300, the compound winding device 400, the face paper unwinding device 500, the chip sticking device 600 and the control module 700 are all arranged on the frame 100 and Located on the same side of the rack 100, the control module 700 in this embodiment uses a single-chip microcomputer as the main control chip, and its model is STC89C51.

[0034] The release paper unwinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com