A strain gauge sticking mechanism

A technology of strain gauges and blades, which is applied in the field of automatic pasting mechanism, can solve the problems of low precision and poor quality of manual pasting, and achieve the effects of improving quality, solving low position precision, and increasing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with specific implementation examples.

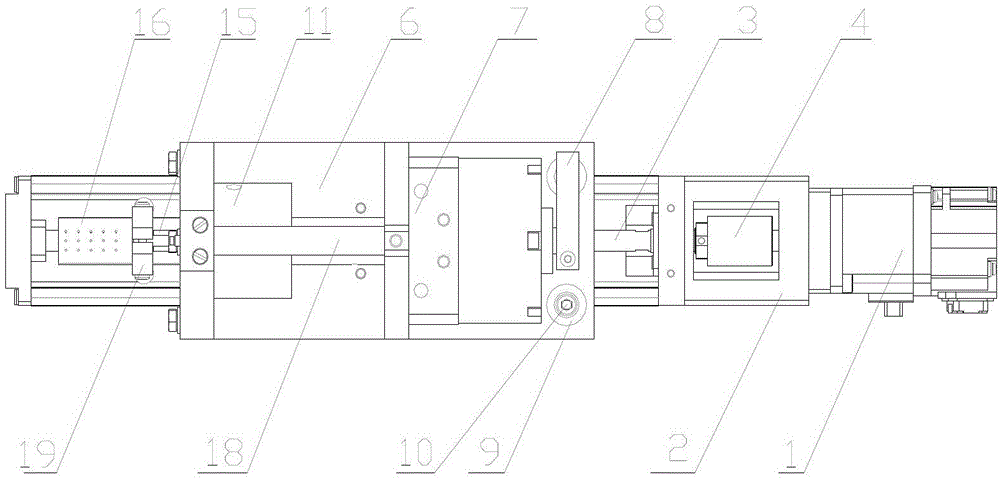

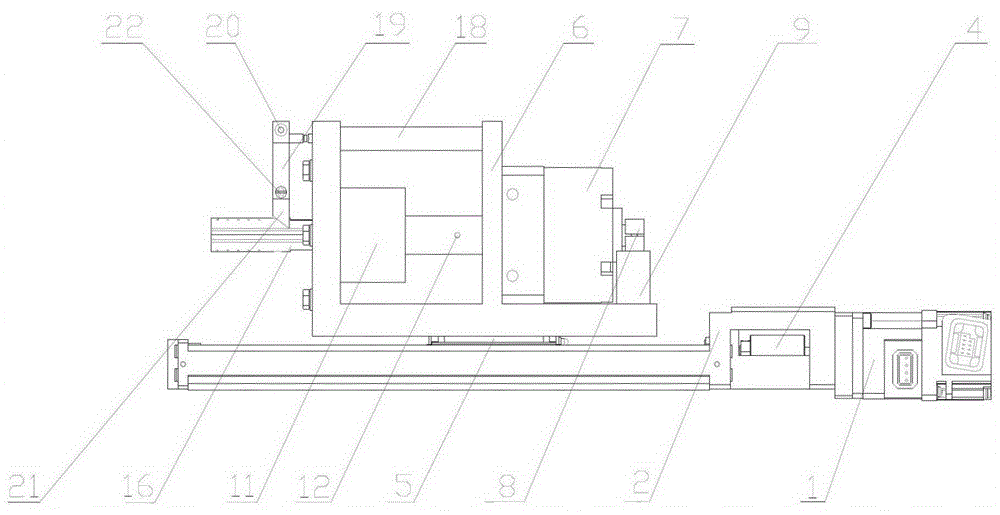

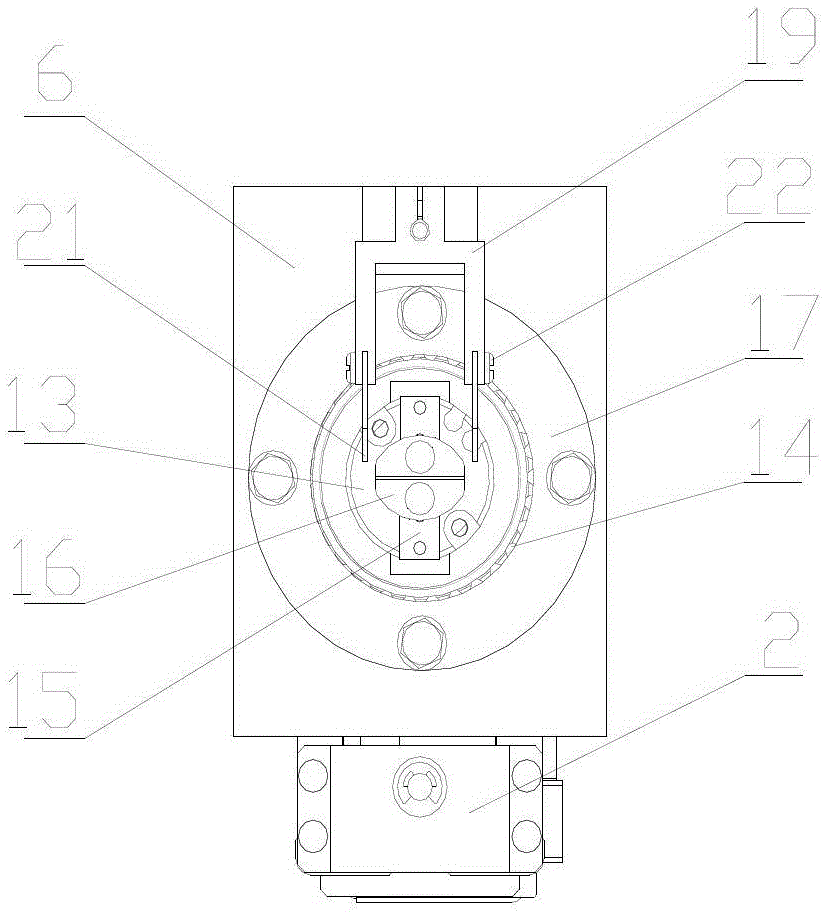

[0014] refer to Figure 1~3 , the present invention includes a servo motor 1, a linear guide rail 2, a lead screw 3, a coupling 4, a slider 5, an F-type motion base 6, a turning cylinder 7, a limit block 8, a limit column 9, an adjustment screw 10, Support sleeve 11, connecting screw 12, air claw 13, bearing 14, L-shaped bracket 15, sticking head 16, bearing end cover 17, telescopic cylinder 18, knife rest 19, knife rest tightening screw 20, blade 21 and blade tightening screw twenty two.

[0015] The linear guide rail 2 in the present invention is fixed on the horizontal workbench, the servo motor 1 is fixed on the linear guide rail 2, the servo motor 1 is connected with the lead screw 3 through the shaft coupling 4, and the slider 5 can be used on the linear guide rail 2 as a For linear motion in the direction, the distance and dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com