Inclined gummed paper pasting device and gummed paper pasting system

A technology of obliquely pasting and sticking glued paper, which is applied in the directions of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of unfavorable production costs, increase labor force, reduce production costs, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

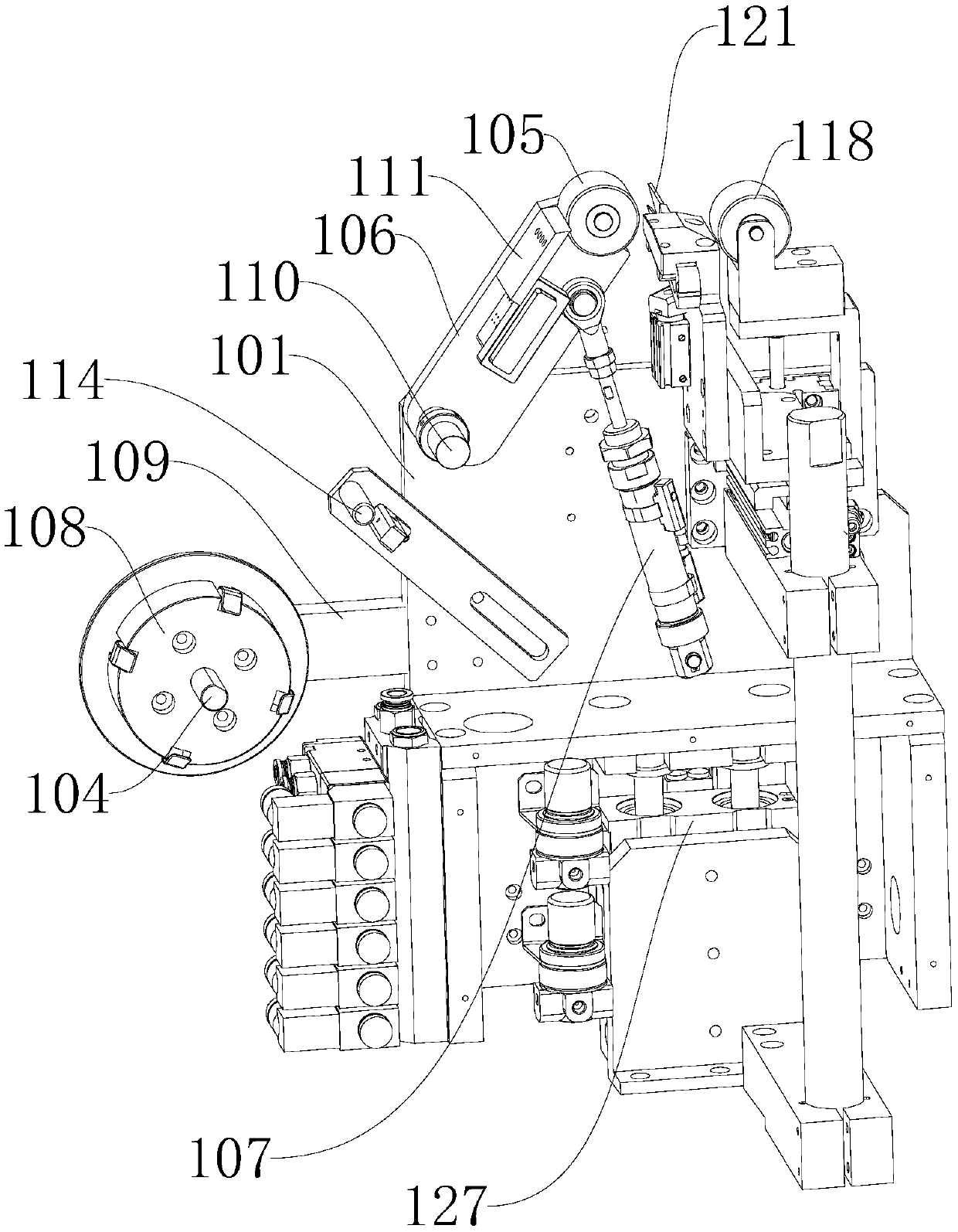

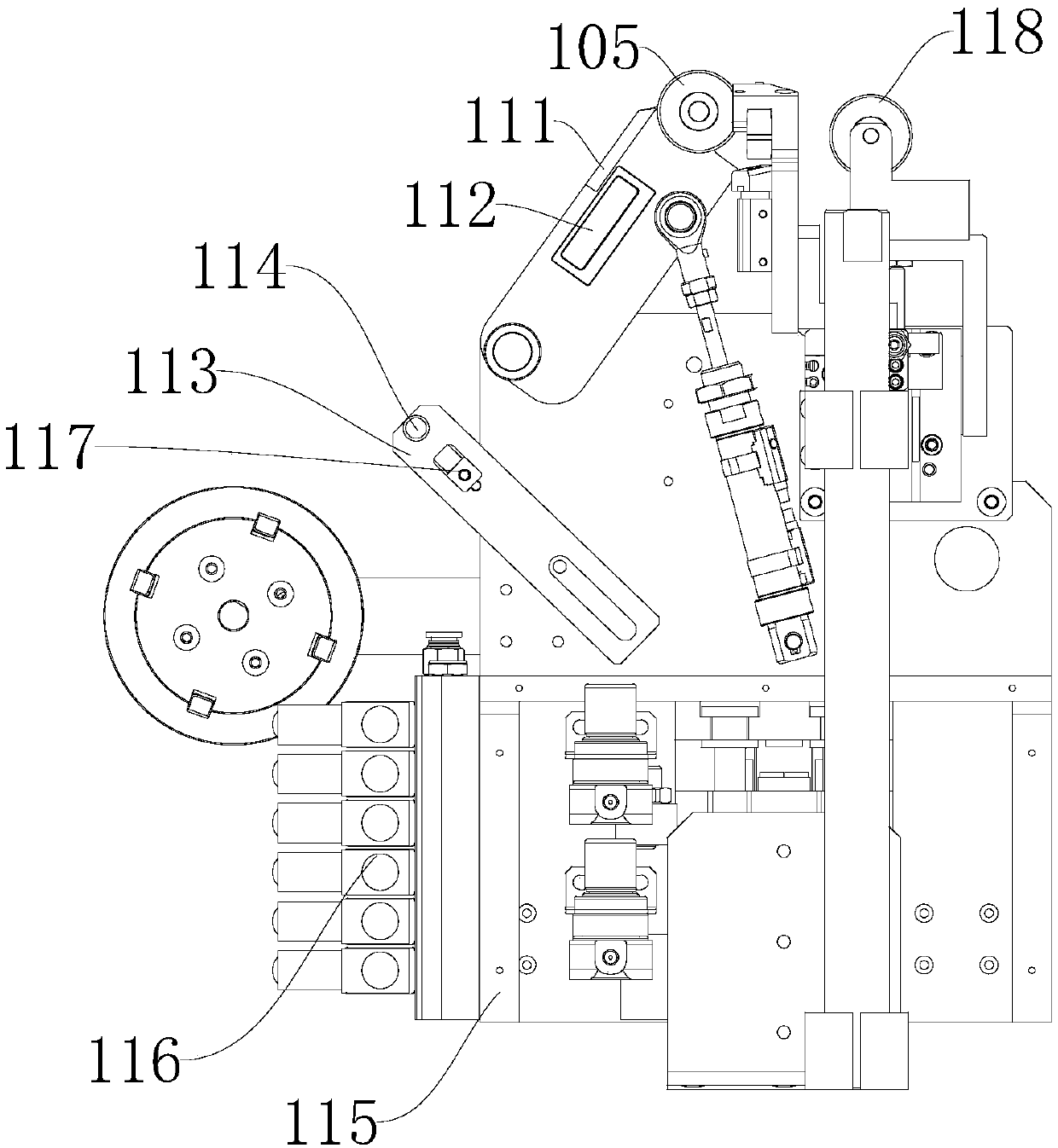

[0043] see Figure 1 to Figure 10 As shown, among them, Figure 7 The trace of the adhesive tape is shown in . Embodiment 1 of the present invention provides a kind of inclined adhesive tape device including support plate 101, adhesive tape assembly, pressure wheel assembly and shearing assembly, adhesive tape assembly and pressure wheel assembly are installed on support plate 101; To provide adhesive tape 102, and paste the adhesive tape to the surface of the product to be pasted; the pressing wheel assembly is used to press the adhesive tape that has been pasted to the surface of the product to be pasted; The adhesive tape on the surface of the product is separated from the adhesive tape assembly.

[0044] Specifically, the adhesive tape assembly is used in conjunction with the pressure wheel assembly; when in use, after one end of the adhesive tape provided by the adhesive tape assembly is attached to the surface of the product to be pasted, a relative movement occurs betwe...

Embodiment 2

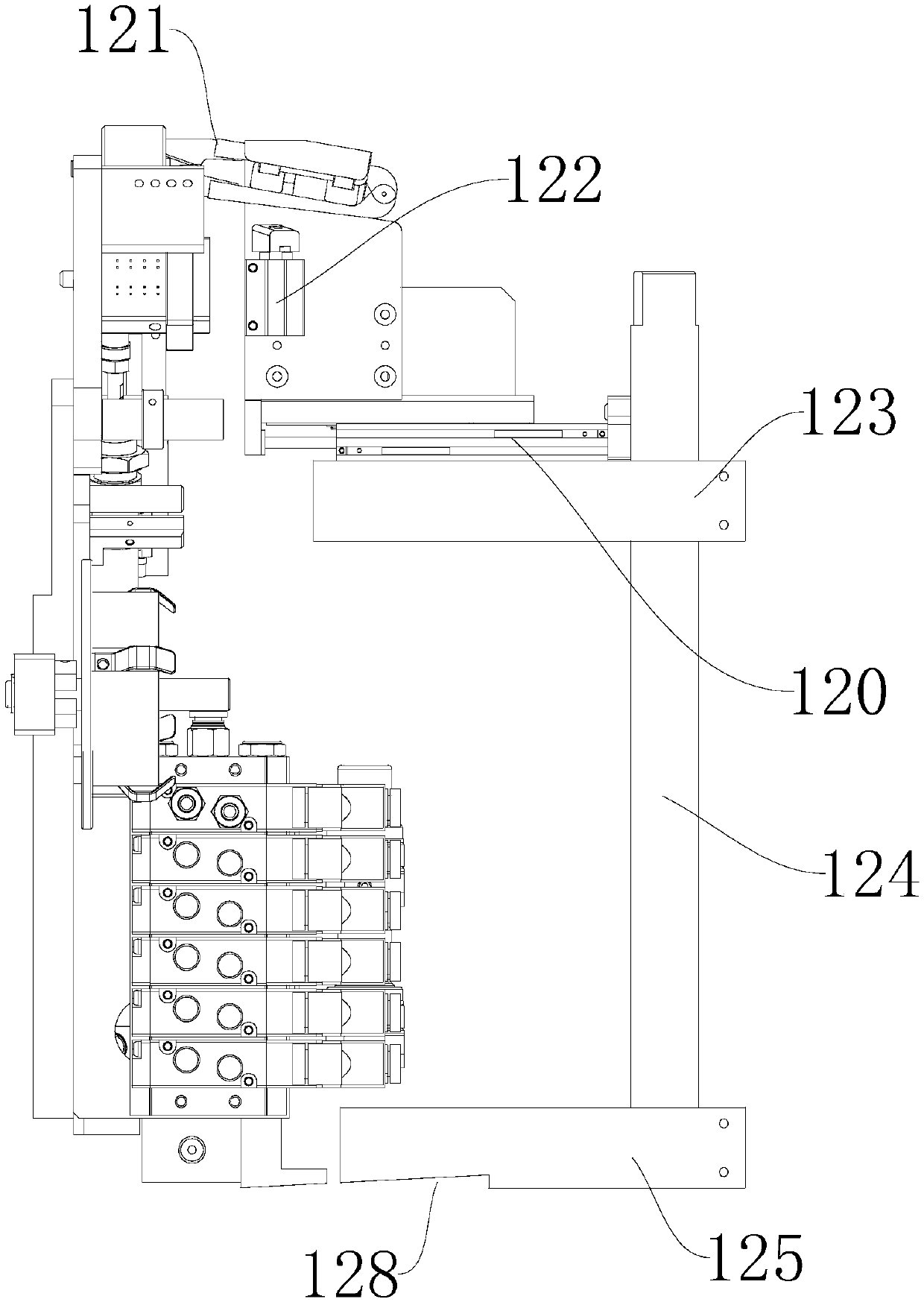

[0064] Embodiment 2 of the present invention provides a glued paper system, including the inclined glued paper device provided in Embodiment 1.

[0065] see Figure 11 to Figure 17 As shown, in this embodiment, the adhesive paper application system further includes a translation device, which is used to drive the inclined adhesive paper application device to perform a translational movement.

[0066] Specifically, the translation device includes a system base plate 201 , a screw drive assembly, a guide device and a drive device 202 . The lead screw drive assembly includes a lead screw 203 and bearing housings 204 installed at both ends of the lead screw; the guiding device includes two guide rails 205 arranged at intervals in parallel; the two guide rails 205 are located on both sides of the lead screw respectively; The length direction of the rod is parallel; the driving device 202 is connected with one end of the lead screw through a coupling 206 for driving the lead screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com