Canvas shoe sole inner layer adhesive tape pasting treatment method

A processing method and glue strip technology, which is applied in the field of canvas shoes, can solve the problems of sticking folds and gaps on the sole, easy to open the glue, and uneven distribution of adhesives, etc., and achieve the effect of firm and tight sticking of the sole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

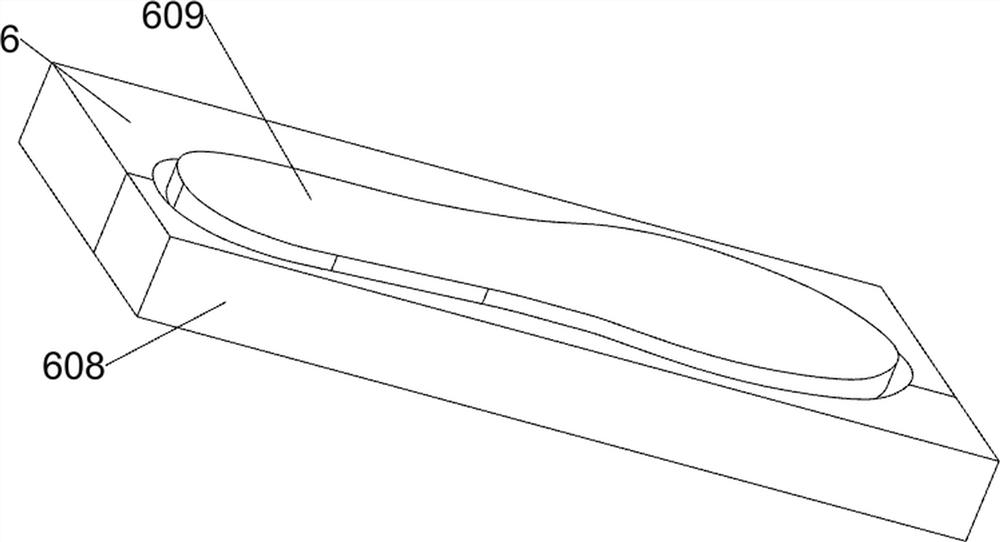

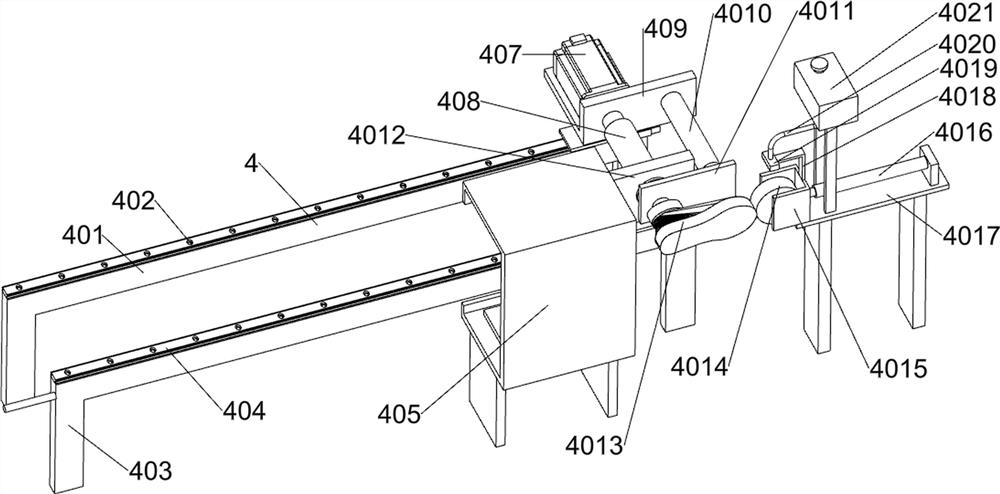

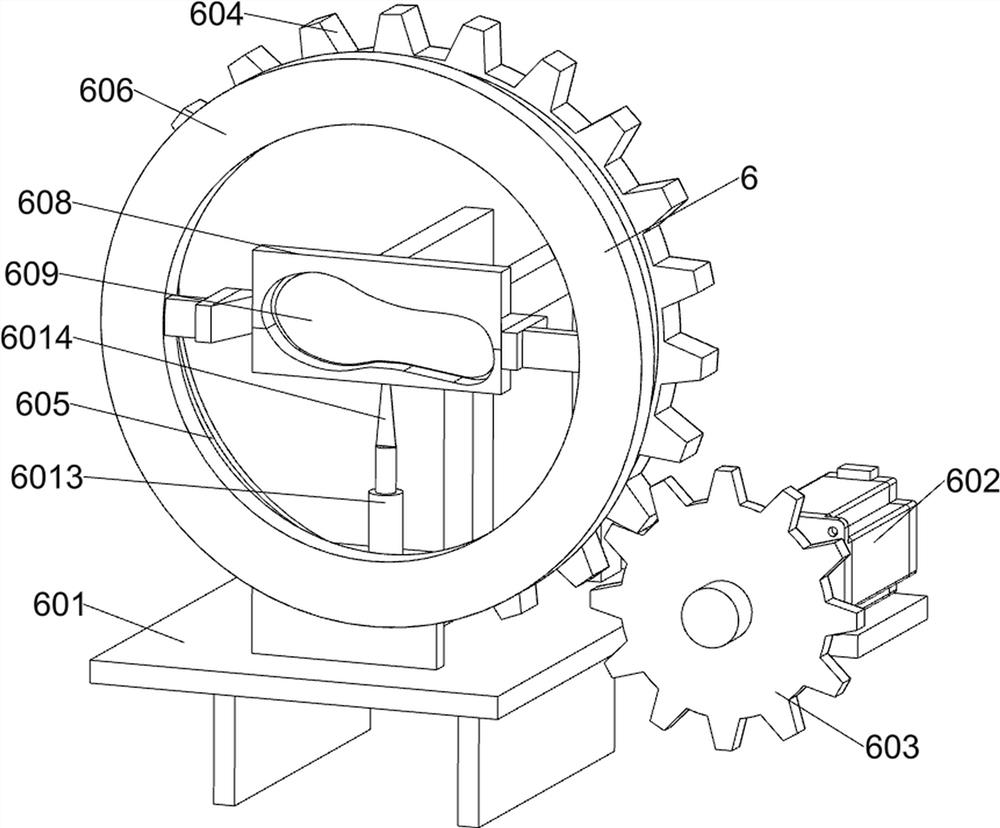

[0035] A method for pasting adhesive strips on the inner layer of canvas shoes, such as Figure 1-10 As shown, the processing method for pasting the inner rubber strip of the canvas shoe sole adopts the following processing equipment, the processing equipment includes a working machine plate 1, a support tripod 2, an operation control panel 3, an adhesive attachment system 4, and a strip pasting system 5 and the margin separation system 6; the lower part of the working machine tool board 1 is welded with the support tripod 2; the working machine tool board 1 is connected with the operation control panel 3; the lower part of the adhesive attachment system 4 is connected with the working machine tool board 1; the rubber strip The bottom of the pasting system 5 is connected with the working machine board 1; the bottom of the margin separation system 6 is connected with the working machine board 1;

[0036] The method for adhering the inner rubber strip of the canvas shoe sole com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com