Crankshaft labelling device

A crankshaft, vertically placed technology, applied in the field of crankshaft processing, can solve the problems of low paste efficiency, difficult separation of the adhesive layer and the paper layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is further described in detail through specific implementation methods:

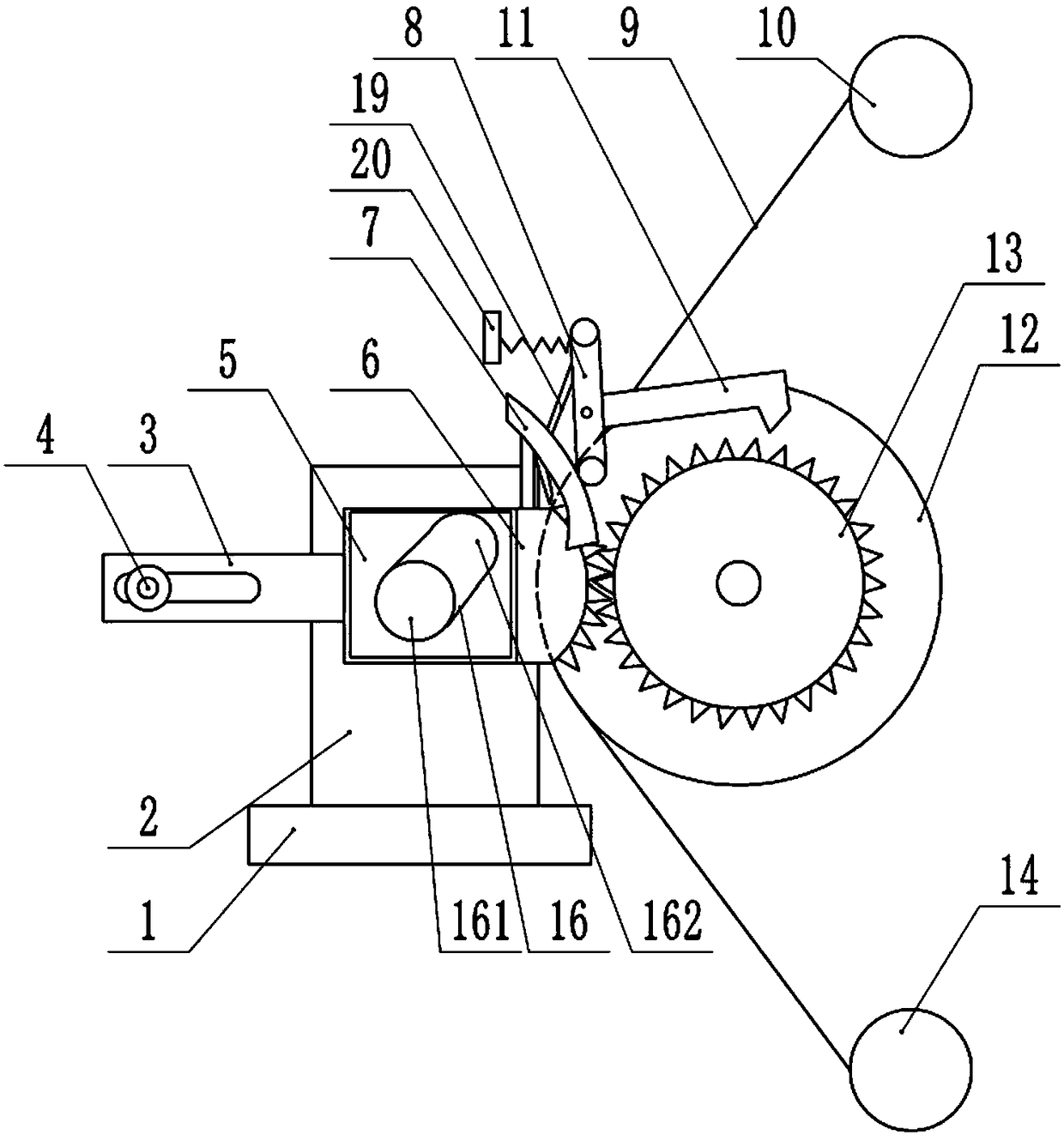

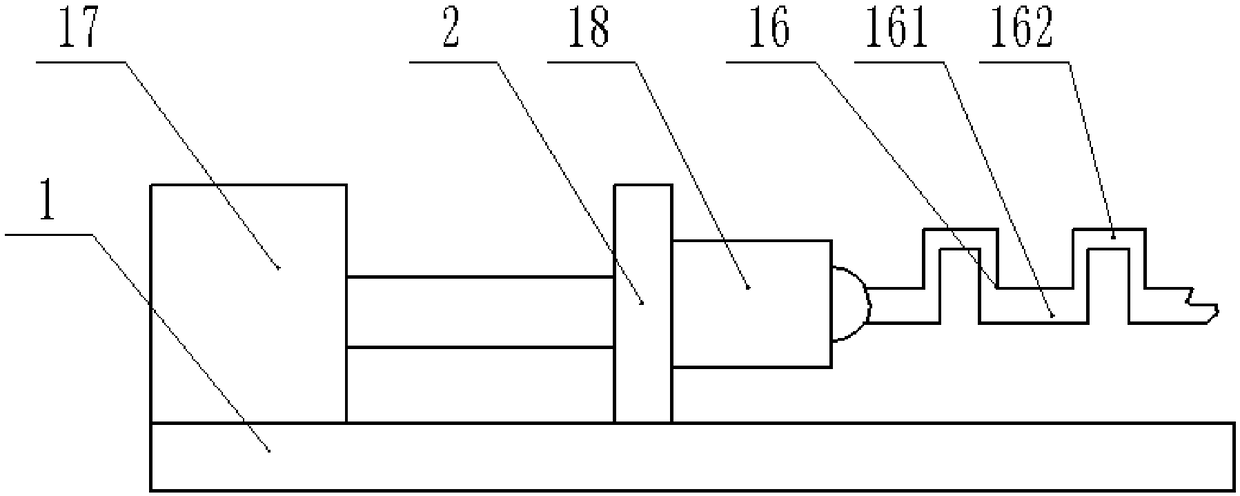

[0015] The reference signs in the drawings of the description include: slide rail 1, slide plate 2, connecting piece 3, screw 4, through hole 5, swing plate 6, arc rod 7, vertical rod 8, double-sided adhesive tape 9, discharge roller 10 , Clamping rod 11, rolling disc 12, gear 13, receiving roller 14, crankshaft 16, main journal 161, connecting rod journal 162, cylinder 17, motor 18, blade 19, baffle plate 20.

[0016] The embodiment is basically as attached Figure 1-Figure 2 Shown: A crankshaft labeling device, including a frame, such as figure 2 As shown, the frame is provided with a horizontal slide rail 1, and the slide rail 1 is slidably connected with a vertically placed slide plate 2. The right side of the slide plate 2 is welded with a motor 18 connected to the crankshaft 16, and the motor 18 is provided with a heat sink. Sheet, the left end of slide rail 1 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com