Reaction tube label printing, conveying and pasting method

A label sticking and reaction tube technology, which is applied in the direction of labels, labeling machines, winding strips, etc., can solve the problems that the process cannot be automated, and achieve the effects of easy movement, stable operation, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

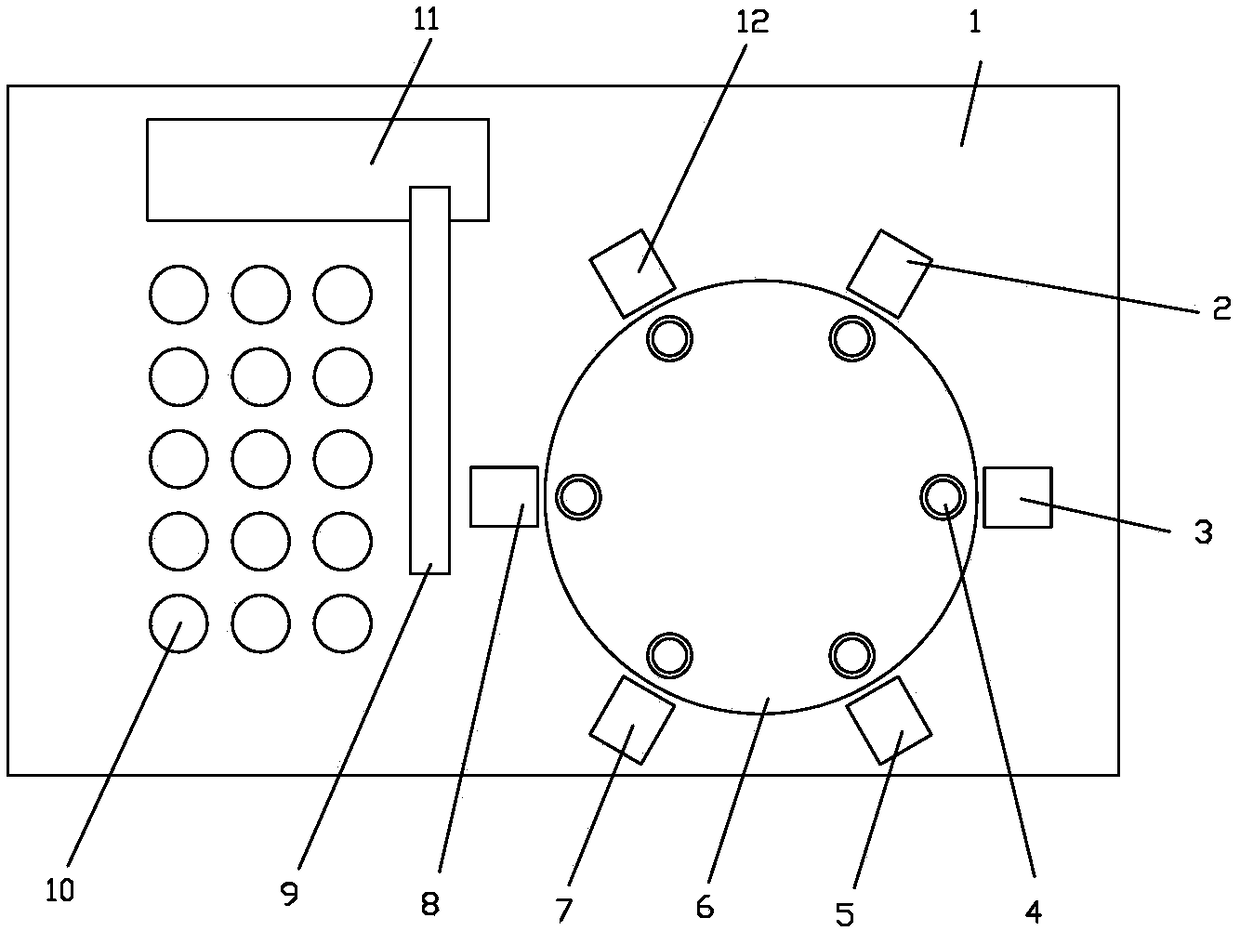

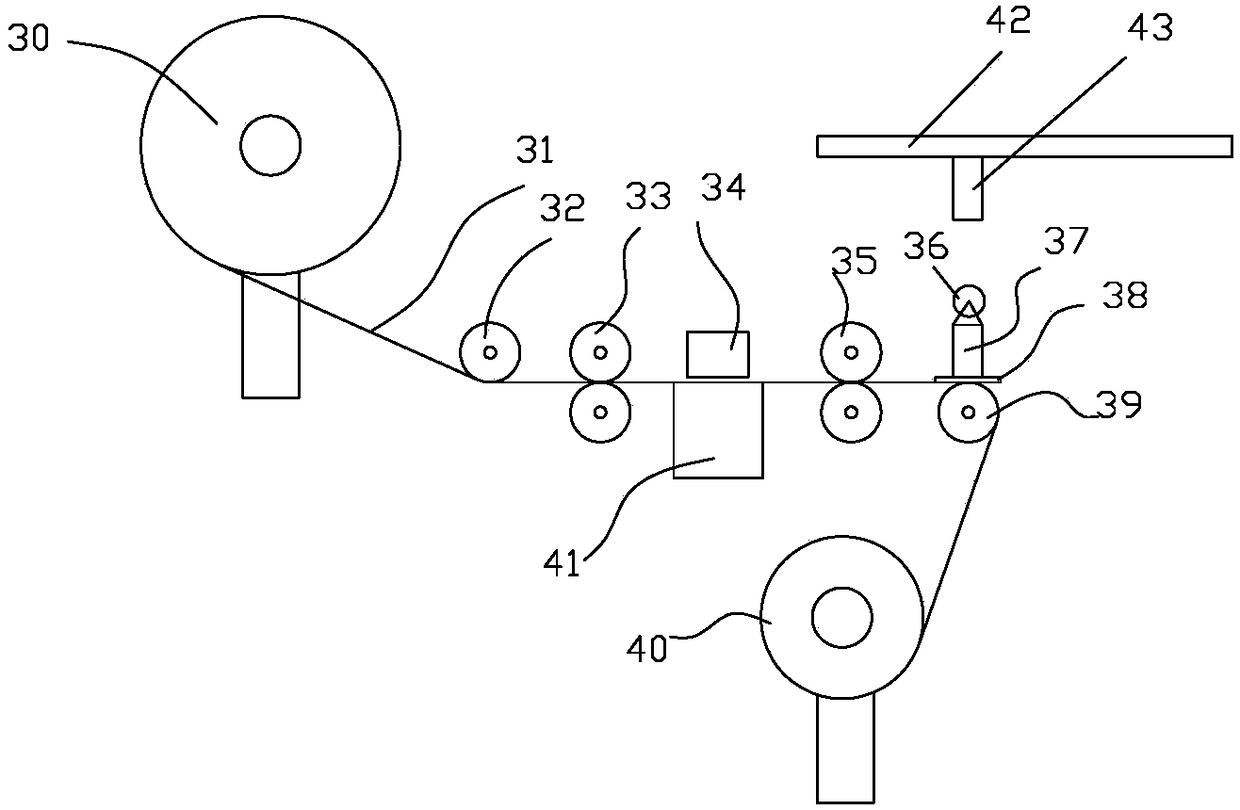

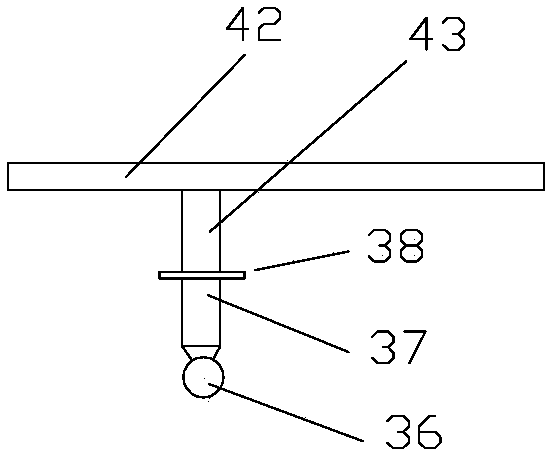

[0080] Embodiment 1: as Figure 1-9 , the detection system, detection method, reaction tube label printing, transmission and pasting system and method are described in detail as follows:

[0081] (1): Automatic sample analysis and detection system, including base 1, turntable 6, liquid injection device, cleaning device 7, detection device 5 and manipulator 9;

[0082] The turntable, liquid injection device, cleaning device, detection device and manipulator are all set on the base;

[0083] Liquid injection device, cleaning device and detection device are all set around the turntable;

[0084] The turntable is provided with a plurality of reaction tube accommodation holes 4; the plurality of reaction tube accommodation holes are evenly arranged along the circumference of the turntable;

[0085] The manipulator is used to move the reaction tubes into the reaction tube accommodation holes, and move the reaction tubes in the reaction tube accommodation holes out of the turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com