Air distribution system for manufacturing engine heat insulation layer and control method of air distribution system

A technology of air distribution system and control method, applied in the direction of control lamination, chemical instruments and methods, lamination, etc., can solve the problems of profile quality, debonding, wrinkling, etc., to improve the bonding effect and bonding quality And the appearance quality of the profile is improved, and the effect of eliminating local wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

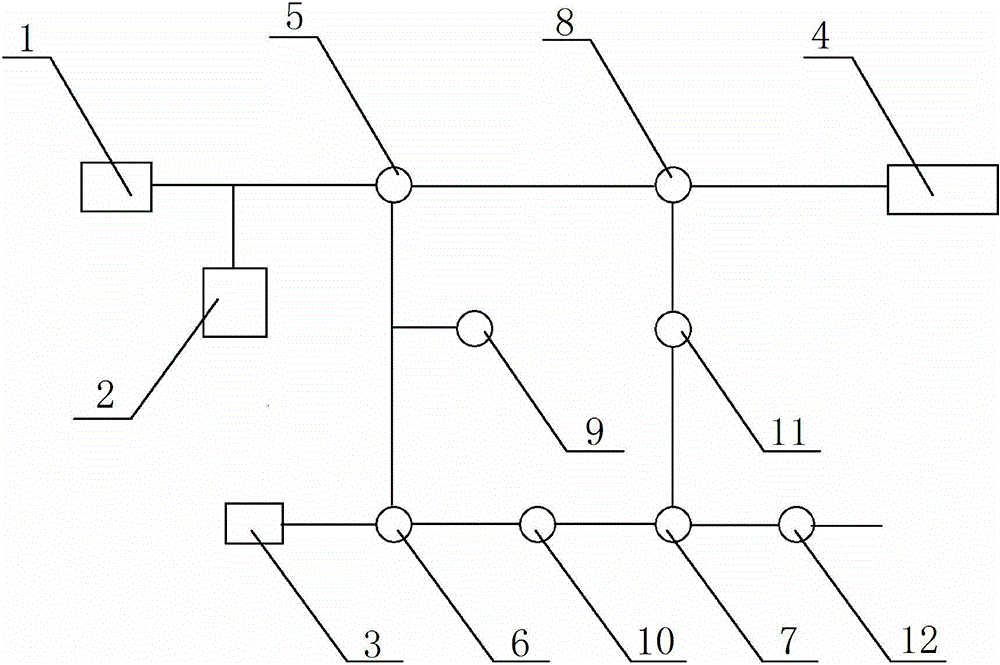

[0021] An air distribution system for the manufacture of engine insulation layer, comprising a first transfer valve 5, a second transfer valve 6, a third transfer valve 7 and a fourth transfer valve 8 connected by pipes in sequence. The connecting valve 8 is connected with the first switching valve 5 to form a circulation channel, wherein the first switching valve 5 is also connected with the vacuum pump 1 and the vacuum chamber 2, the second switching valve 6 is connected with the rubber air bag 3, and the third switching valve 7 An emptying pipeline is also provided, and the fourth transfer valve 8 is also connected to an air compressor 4. A pressure gauge 9 is installed between the first switching valve 5 and the second switching valve 6.

[0022] The specific steps of the control method of the system are:

[0023] 1) Put the heat insulation layer material inside the engine casing, and place the rubber air bag 3 inside the heat insulation layer material, then place the engine i...

Embodiment 2

[0029] An air distribution system for the manufacture of engine insulation layer, comprising a first transfer valve 5, a second transfer valve 6, a third transfer valve 7 and a fourth transfer valve 8 connected by pipes in sequence. The connecting valve 8 is connected with the first switching valve 5 to form a circulation channel, wherein the first switching valve 5 is also connected with the vacuum pump 1 and the vacuum chamber 2, the second switching valve 6 is connected with the rubber air bag 3, and the third switching valve 7 An emptying pipeline is also provided, and the fourth transfer valve 8 is also connected to an air compressor 4. A pressure gauge 9 is installed between the first switching valve 5 and the second switching valve 6. A flow monitor 10 is installed between the second switching valve 6 and the third switching valve 7.

[0030] The specific steps of the control method of the system are:

[0031] 1) Put the heat insulation layer material inside the engine cas...

Embodiment 3

[0037] An air distribution system for the manufacture of engine insulation layer, comprising a first transfer valve 5, a second transfer valve 6, a third transfer valve 7 and a fourth transfer valve 8 connected by pipes in sequence. The connecting valve 8 is connected with the first switching valve 5 to form a circulation channel, wherein the first switching valve 5 is also connected with the vacuum pump 1 and the vacuum chamber 2, the second switching valve 6 is connected with the rubber air bag 3, and the third switching valve 7 An emptying pipeline is also provided, and the fourth transfer valve 8 is also connected to an air compressor 4. A pressure gauge 9 is installed between the first switching valve 5 and the second switching valve 6. A flow monitor 10 is installed between the second switching valve 6 and the third switching valve 7. A first quantitative valve 11 is installed between the third switching valve 7 and the fourth switching valve 8, and a second quantitative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com