Special drug-loading hot-melt pressure-sensitive adhesive

A hot-melt pressure-sensitive adhesive and drug-loading technology, which is applied in the field of medical materials, can solve the problems that the antibacterial effect is not optimal and the drug-loading effect is not optimal, and achieve good drug-loading effect, improve viscosity, and inhibit good effect of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

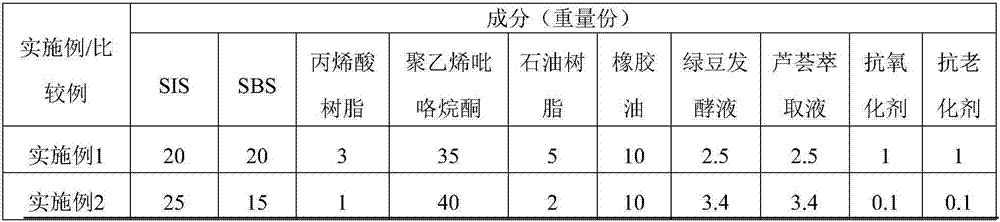

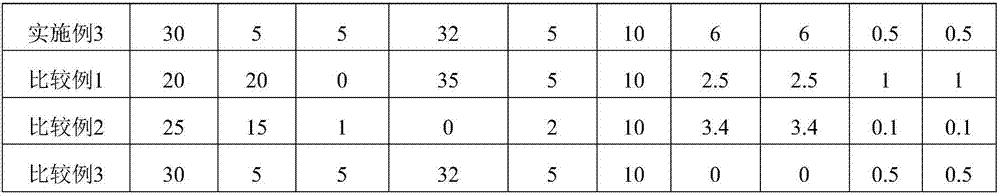

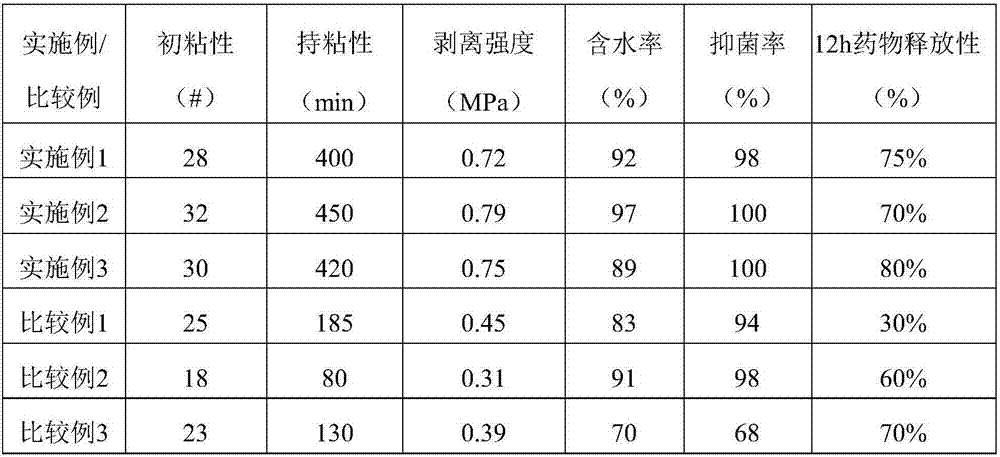

[0020] The invention relates to a special hot-melt pressure-sensitive adhesive for drug loading, the components of which are: SIS thermoplastic elastomer (styrene-isoprene-styrene block copolymer) 20-30 parts, acrylic acid 1-5 parts of resin, 5-20 parts of SBS thermoplastic elastomer (styrene-butadiene-styrene block copolymer), 30-50 parts of tackifier, 10-15 parts of plasticizer, 5 parts of antibacterial agent -12 parts, 0.01-1 part of anti-aging agent and the balance of antioxidant, said tackifier is selected from polyvinylpyrrolidone and petroleum resin, rosin resin, terpene resin, terpene-styrene resin, coumarone-terpene A mixed mixture of one type of resin, wherein the polyvinylpyrrolidone accounts for more than 50% by weight of the tackifier.

[0021] In this embodiment, a mixture of SIS thermoplastic elastomer and SBS thermoplastic elastomer is used as the matrix of the hot-melt pressure-sensitive adhesive, which greatly reduces the manufacturing cost; on the basis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com