Composite floor coated with thermosetting polyurethane elastomer and manufacturing method of composite floor

A technology of polyurethane elastomer and polyurethane elasticity, which is applied in the direction of elastic floors, chemical instruments and methods, building structures, etc. It can solve the problems that one piece cannot be disassembled separately and the floor pieces are hooked up, and achieve excellent anti-slip and high and low temperature resistance Excellent performance, convenient laying, and the effect of reducing the cost of floor decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

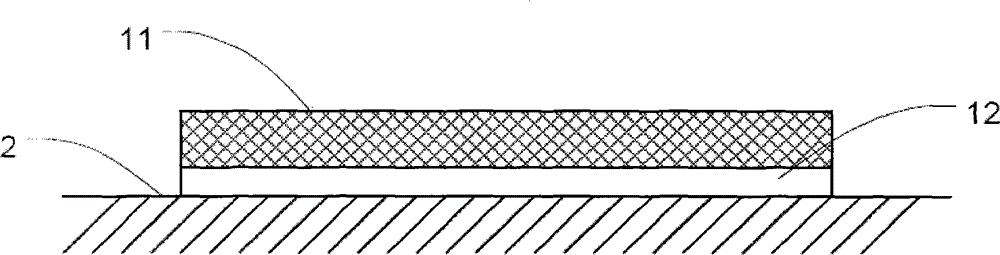

[0020] First, please refer to figure 1 , which is a structural schematic diagram of the present invention; as shown in the figure, it includes a floor surface layer 11 and a polyurethane elastomer layer 12 . Wherein, the polyurethane elastomer layer 12 is disposed under the floor surface layer 11 , and a floor 2 is located below the polyurethane elastomer layer 12 .

[0021] In the present invention, the floor surface layer 11 is a composite floor surface that is exposed to the outside and is used to replace the original ground 2 for users to step on. Therefore, there are no special restrictions on the selection of materials, and any material that can be used as a floor The material is one of the options, such as common glass, rubber,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com