Semi-automatic plane labeler

A labeling machine, semi-automatic technology, applied in the field of semi-automatic flat labeling machines, can solve the problems that the tension of the paper tape cannot be adjusted, affect the conveying effect, affect the effect of label pasting, etc., and achieve the effect of improving the effect of label pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

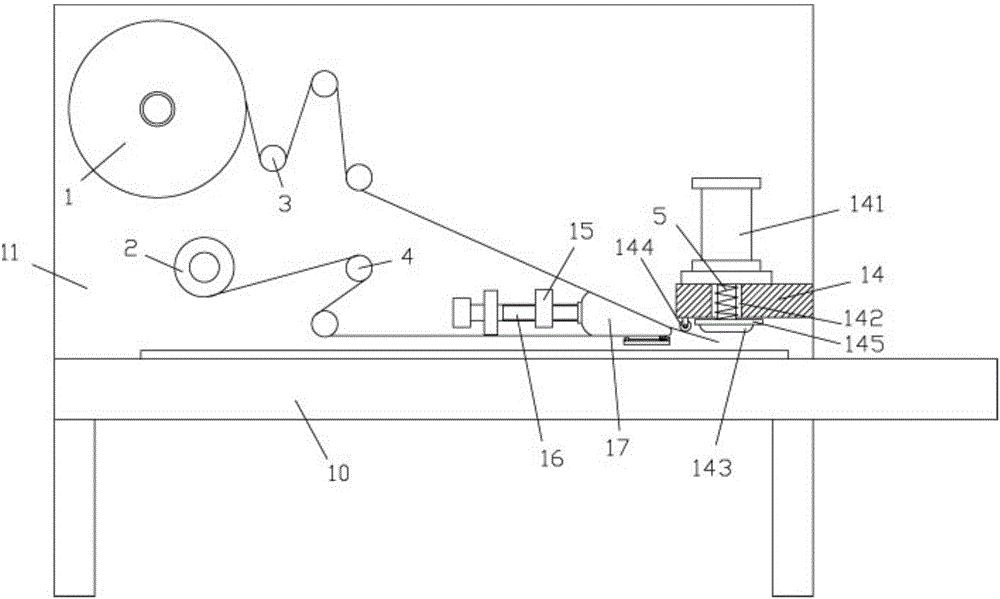

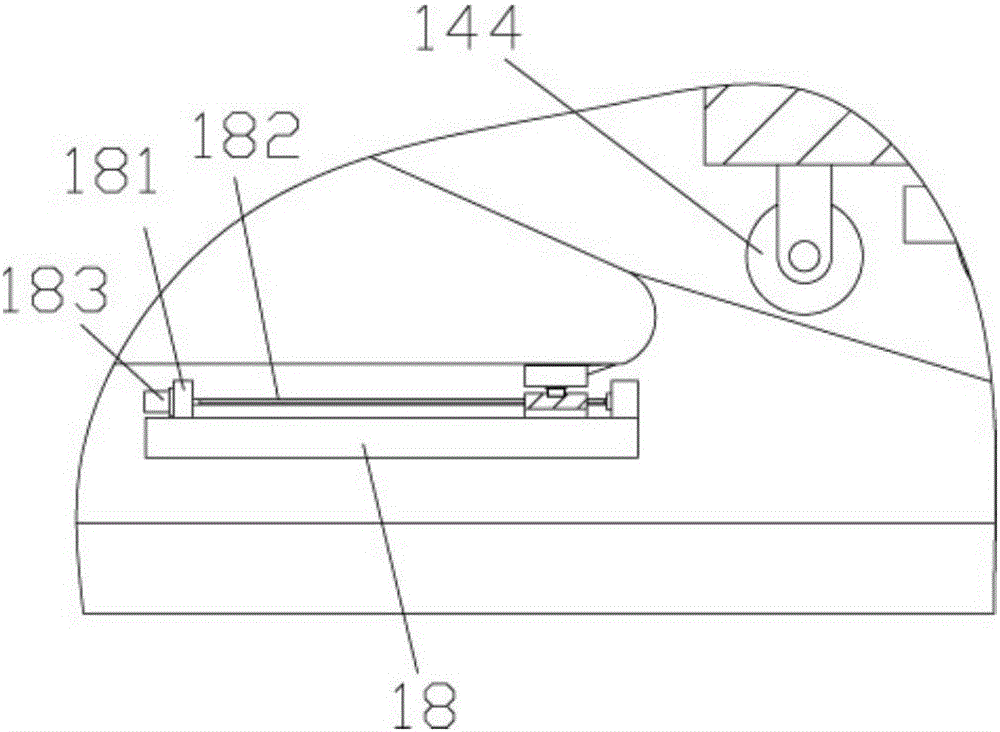

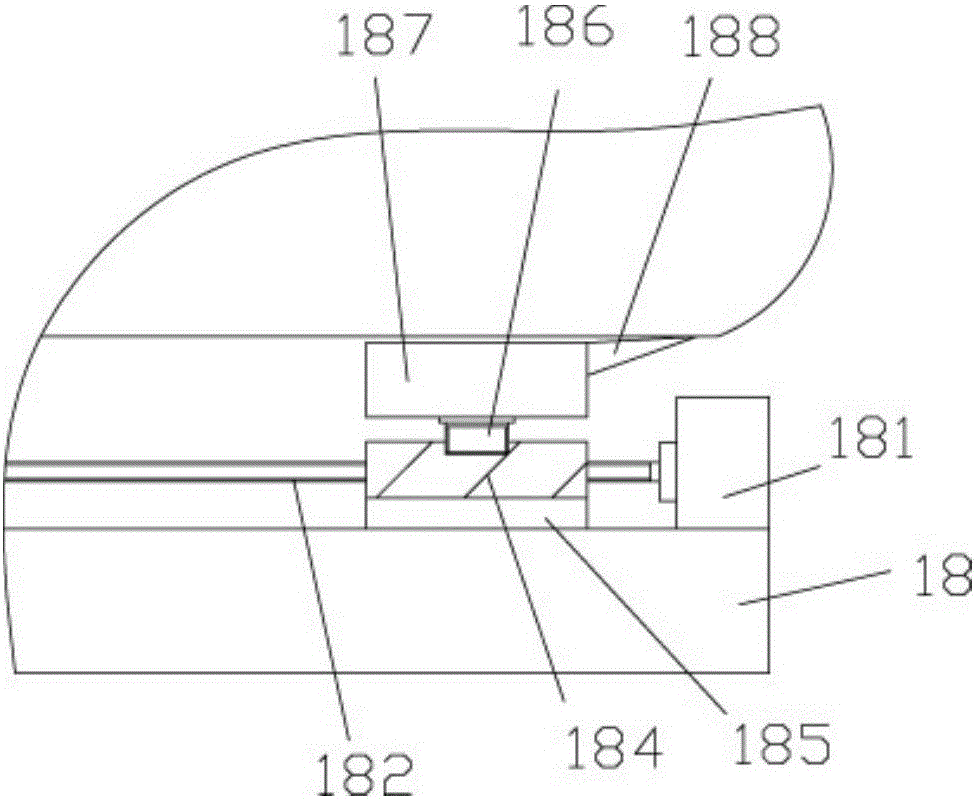

[0022] Examples, see e.g. Figure 1 to Figure 4 As shown, a semi-automatic plane labeling machine includes a frame 10, the rear portion of the top plate of the frame 10 is fixed with a main support plate 11, and the main drive motor 12 is fixed on the upper left side of the main support plate 11. The main drive The output shaft of the motor 12 stretches out the main support plate 11 forward and is equipped with a label reel 1 (the sleeve of the label reel 1 is clamped on the output shaft of the main drive motor 12), the left side of the main support plate 11 below The back side is fixed with auxiliary driving motor 13, and the output shaft of auxiliary driving motor 13 stretches out main support plate 11 forward and is installed with reel 2 (the inwall of reel 2 has spline groove, and the output shaft outside of auxiliary driving motor 13 The wall has a spline protruding strip, and the spline protruding strip is inserted in the spline groove), the upper part of the main suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com