Method for preparing rice milk and soybean milk maker thereof

A technology for rice milk and soy milk, applied to the method and the soymilk machine and the field of soymilk machine-made rice milk, can solve the problems of sticking and pasting, unfavorable cleaning, influence on pulping effect, etc., and achieves good gelatinization effect and good taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

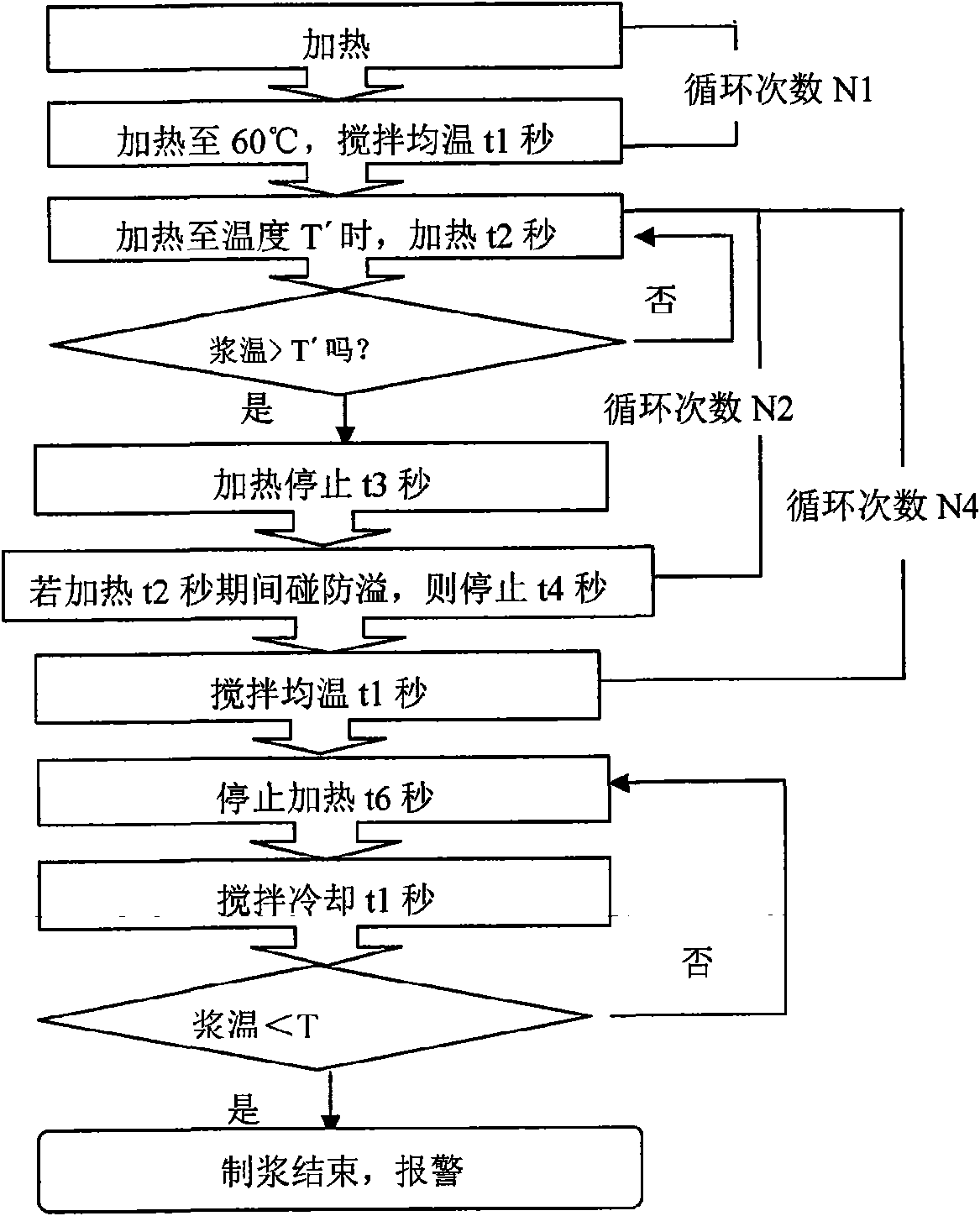

[0032] As embodiment one of the method of making rice milk from soybean milk according to the present invention, as figure 2 Shown, its specific pulping process is as follows:

[0033] (a) Cooking stage: In the cooking stage, the water and materials contained in the cup of the soybean milk machine are heated until the materials are cooked, and then enters the next stage. The purpose of the cooking stage is to ensure the cooking degree of the material, so as to meet the eating requirements of customers.

[0034] In this embodiment, the cooking stage is provided with a process in which the motor drives the pulverizer to stir the water and the materials. The purpose of the stirring is to ensure the balance of the water temperature so that the temperature of the water and the materials in the entire cup body can be uniform. , while preventing rice and other materials from sticking to the bottom. The cooking stage is also provided with an action of stopping heating, and the acti...

Embodiment 2

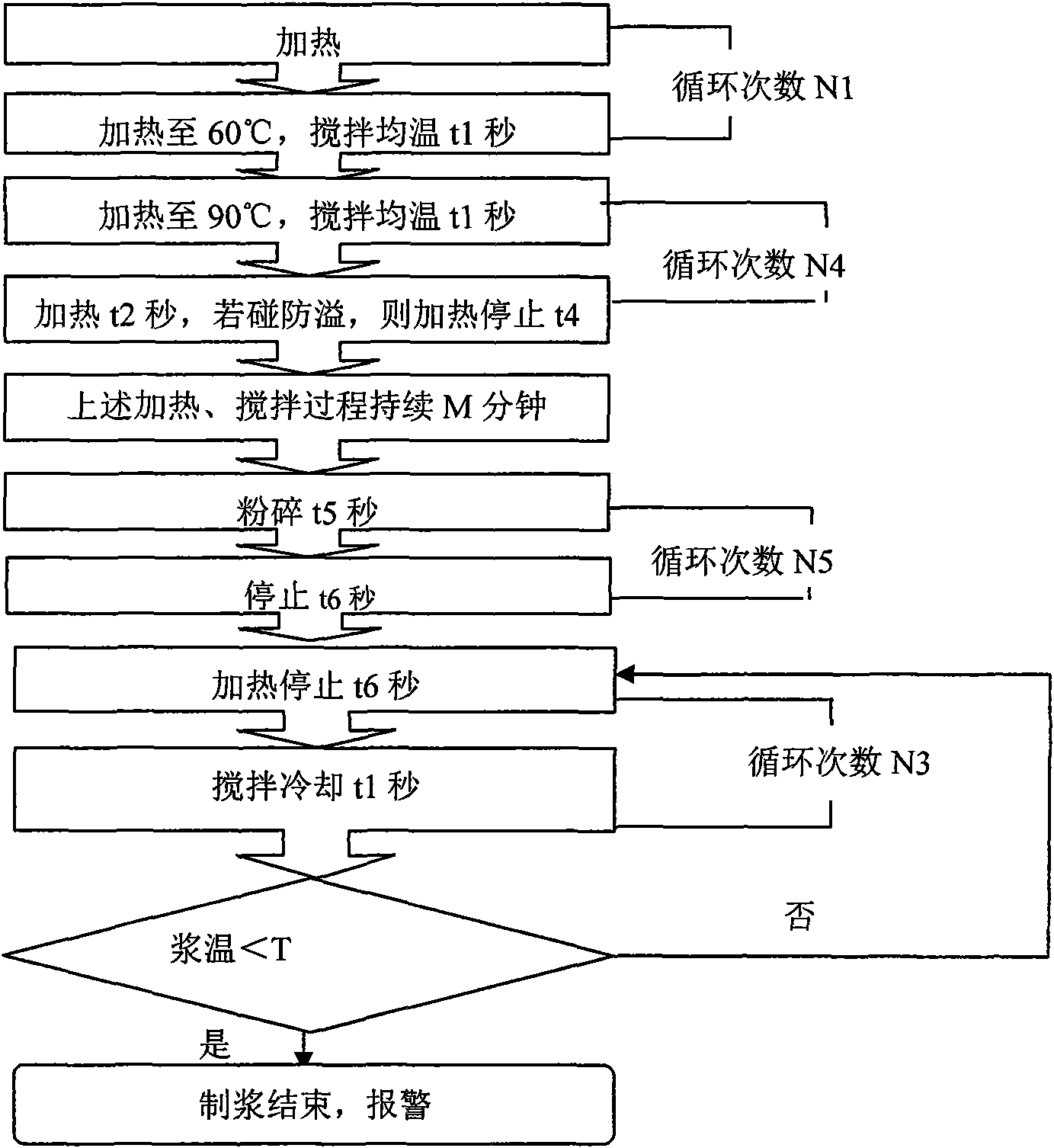

[0039] As embodiment two of the method for making rice milk from soybean milk according to the present invention, as image 3 Shown, its specific pulping process is as follows:

[0040] (a), cooking stage: the difference between the cooking stage of this embodiment and the cooking stage of embodiment 1 is that: the cooking stage is also equipped with a motor to drive the crushing cutter to crush and stop the material until it is made The process of mixing with water to form a slurry, the pulverization process is carried out after cooking. After the material is crushed, gelatinization is more likely to occur. At the same time, the purpose of stopping the crushing is to cool down and gradually reach the gelatinization temperature of the material. The heating stop action of the cooking stage is jointly controlled by time and overflow signal. The rest of the process of the cooking stage and the beneficial effects produced are consistent with the first embodiment, and will not be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com