Robot-based underground pipe network repairing method

A repair method and technology for underground pipe networks, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of curing effect influence, corrosion, pipe joint misalignment, etc., and achieve the effect of improving the paste effect and enhancing the paste performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

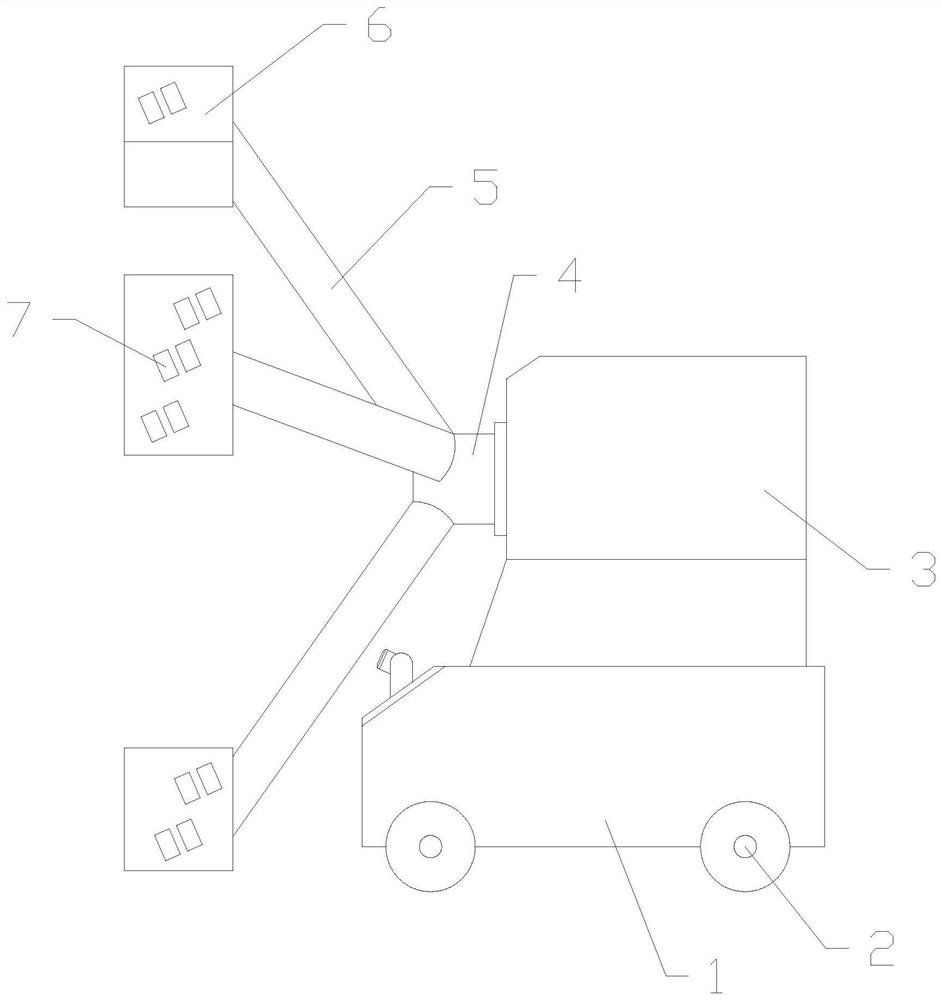

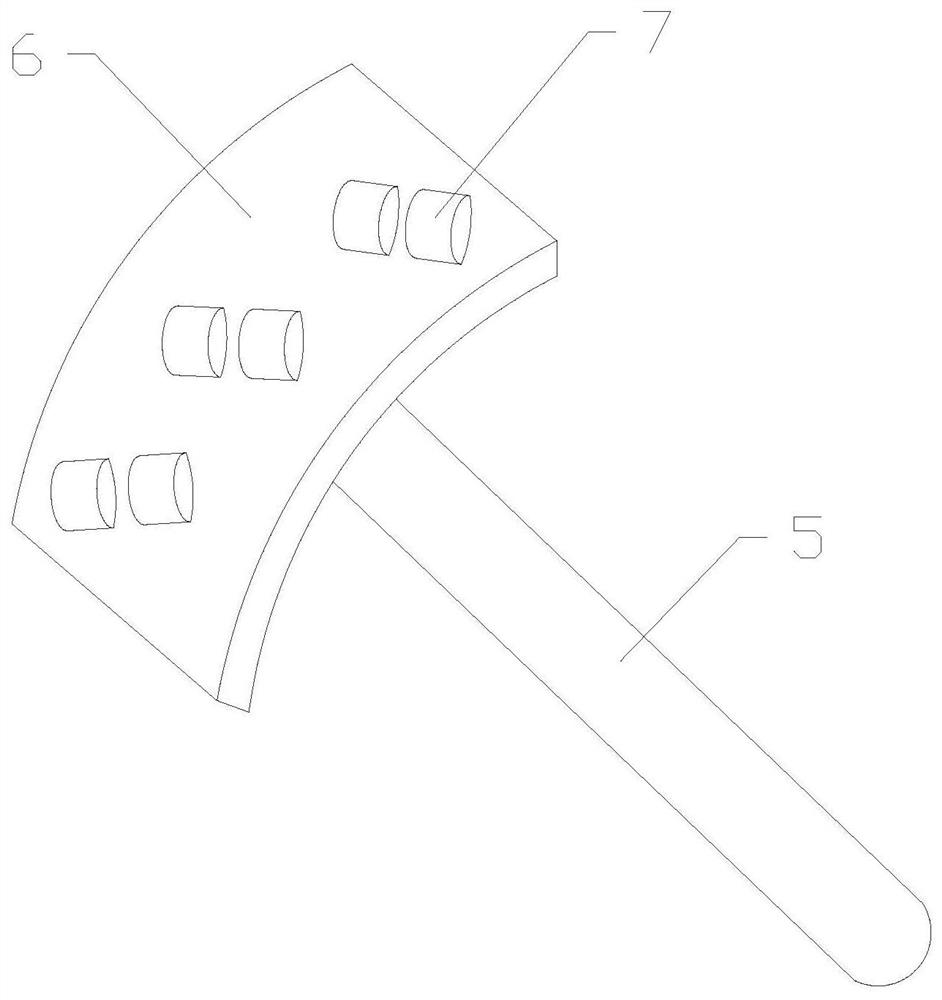

[0029] Please refer to figure 1 , this embodiment provides a robot-based underground pipeline network repair method, which uses a curing robot to assist in the repair of the inner wall of the pipeline. The curing robot includes a main body 1, wheels 2, cameras, servo motors 3, rotating joints 4, and steering rods 5 , hoop arc sheet 6 and pressure roller 7, wherein pressure roller 7, steering rod 5 and hoop arc sheet 6 form hoop assembly, and hoop assembly is the parts of solidifying robot, and solidifying robot passes camera to urban pipeline The scenes in the inner or lined pipe are photographed and collected, and the urban pipeline is repaired through the ring component, that is, the pressure is applied to the inner wall of the lined pipe by the pressure roller 7, and the pressure is applied by the pressure roller to cure the inner liner. The pipe is tightly attached to the inner wall of the repaired pipe, which enhances the repair effect of the lined pipe.

[0030] Please ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com