Waterproofing compound and construction method using the compound

A compound, emulsified asphalt technology, applied in asphalt coatings, carboxyl rubber coatings, building structures, etc., can solve the problems of quality deterioration, low resilience, low cold resistance, etc., to improve cold resistance and adhesion, improve viscosity and The effect of restoring force and improving chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific exemplary embodiments of the present invention will be described in detail below, but the present invention is not limited by the embodiments. When describing the present invention, existing functions or structures may be omitted to clearly illustrate the present invention.

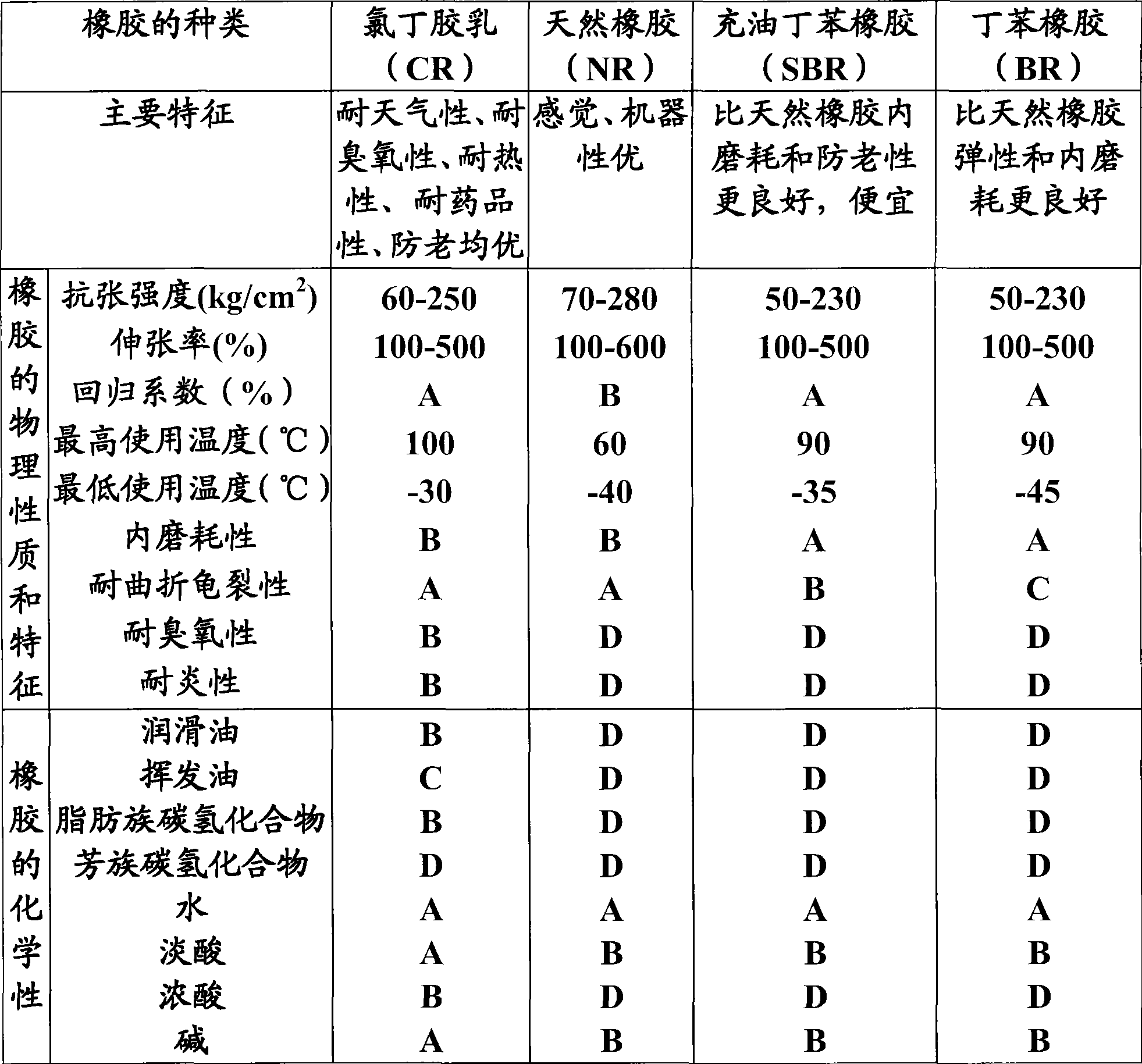

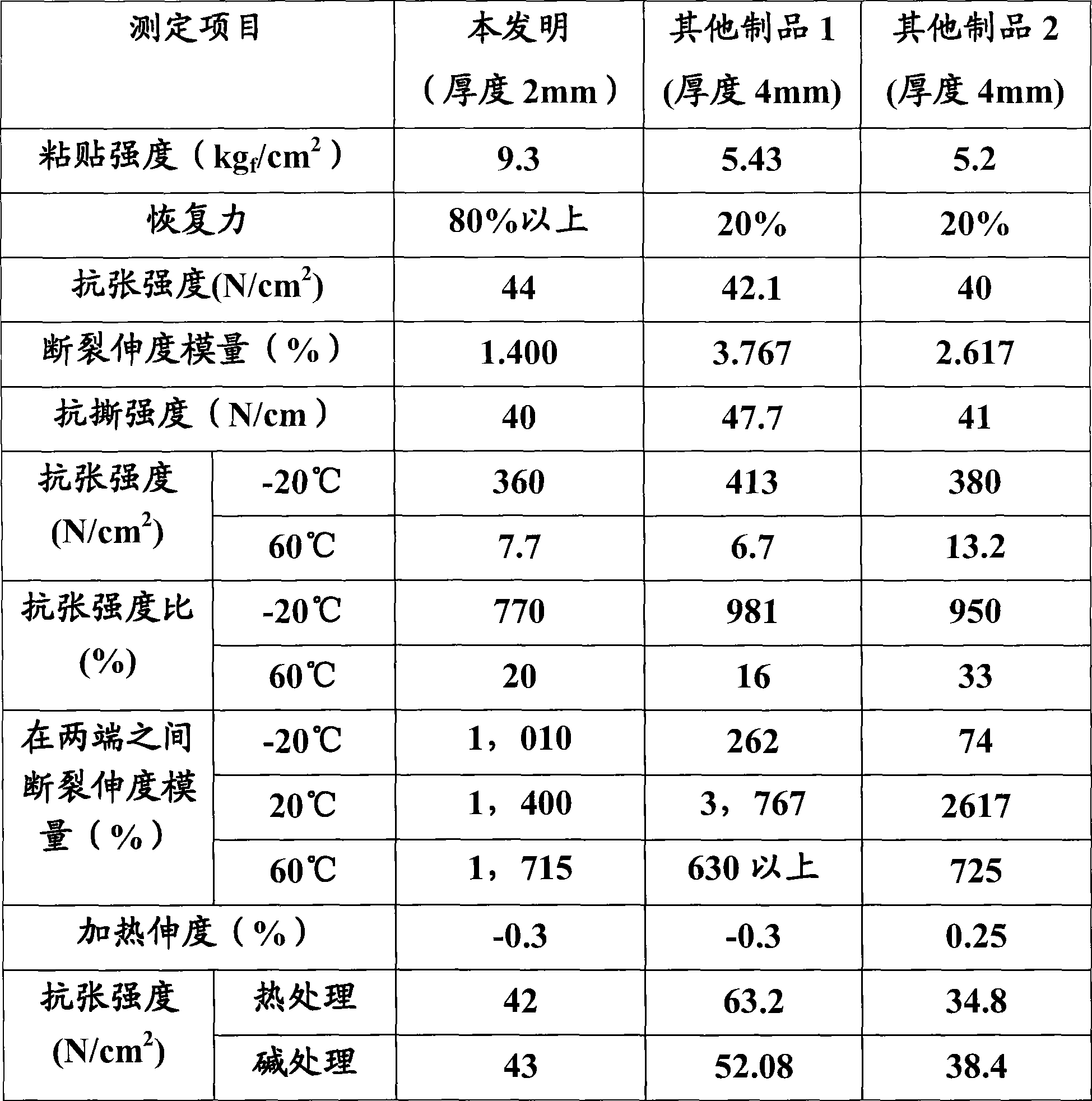

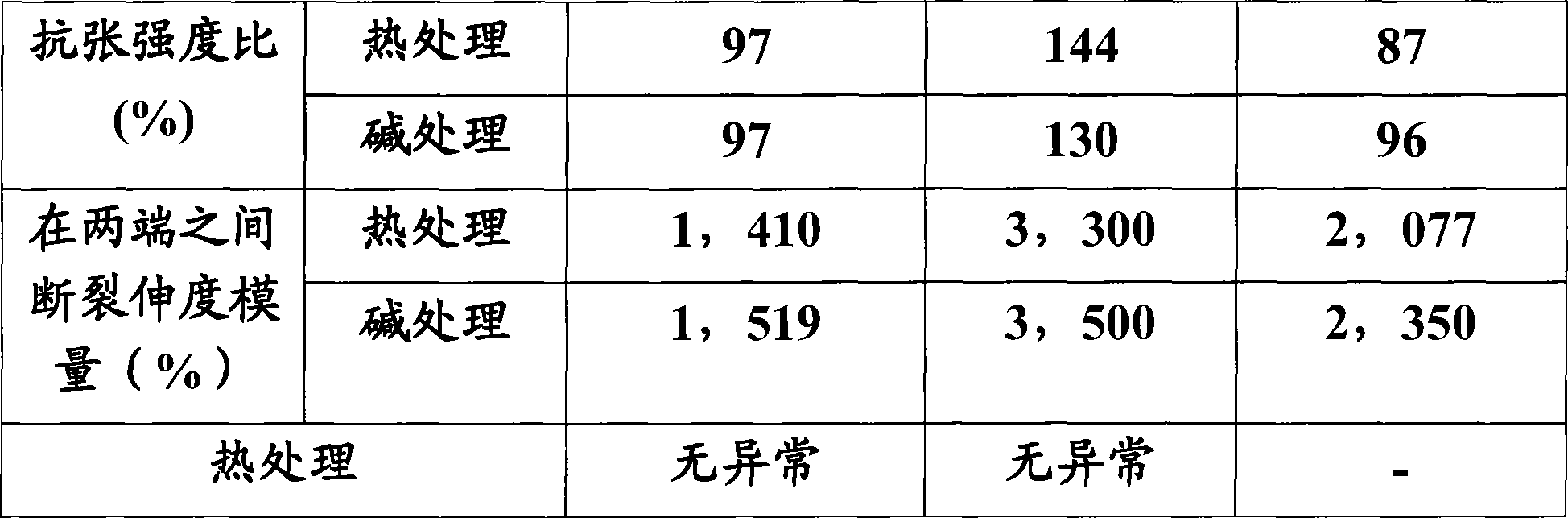

[0025] The waterproof compound according to the present invention comprises 100 parts by weight of neoprene latex, 100 parts by weight of neoprene latex mixed to provide a pH of 7-12, 160-240 parts by weight of oil-extended styrene butadiene rubber, and carboxyl butadiene styrene 160-240 parts by weight of rubber, 90-1600 parts by weight of emulsified asphalt, and 2-100 parts by weight of additives. The asphalt waterproof compound mixed in this way and the mixed agent including the purifying water and the hardening agent (metal dichloride) are sprayed separately on the covered part through the sprayer, and the waterproof compound and the mixed agent are mixed together at the moment of spraying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com