Alternating-type alpha gelatinization-aging processing method for instant potato noodle

A potato noodle, alternating technology, applied in food preparation, food science, application, etc., can solve the problems of lack of staple food, edible, etc., and achieve the effect of good elasticity, smooth taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

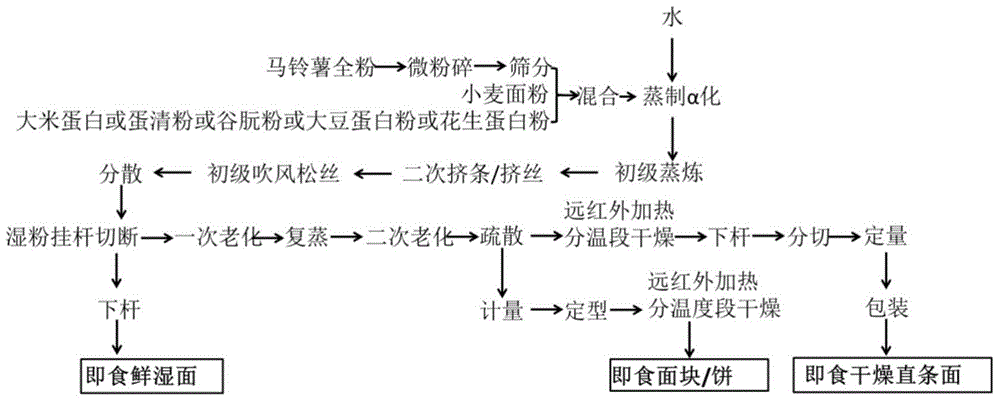

Method used

Image

Examples

Embodiment 1

[0052] The invention provides an instant potato noodle. The dosage of each raw material is: 15g of whole potato powder, 15g of wheat flour, 5g of rice protein and egg white powder in total.

[0053] The production process includes the following steps:

[0054] (1) Mix 15g of whole potato flour, 15g of wheat flour, 5g of rice protein and egg white powder, add 1.4g of water, and grind to make the fineness of the mixed flour less than 120 mesh;

[0055] (2) Adding 7.7g of water equivalent to the weight of the mixed powder to the mixed powder, followed by gelatinization steaming, primary steaming and secondary extrusion to obtain primary noodles, wherein the temperature of the gelatinization steaming 95°C, the steaming time is 10 minutes, the temperature of the primary steaming is 80°C, and the steaming time is 30 seconds; and,

[0056] (3) The primary noodles are blown and loosened. The temperature for blowing and loosening is 15° C., and the wind speed is 2.2 m / s until the prim...

Embodiment 2

[0058] The invention provides a kind of instant potato noodles. The dosage of each raw material is: 75g of whole potato powder, 40g of wheat flour, 10g of gluten powder and soybean protein powder in total.

[0059] The production process includes the following steps:

[0060] (1) 75g of whole potato powder, 40g of wheat flour, 10g of gluten powder and soybean protein powder are mixed altogether, add 10g of water, grind, make the fineness of mixed powder less than 120 orders;

[0061] (2) Adding water equivalent to 35g of the weight of the mixed powder into the mixed powder, followed by gelatinization steaming, primary steaming and secondary extrusion to obtain primary noodles, wherein the temperature of the gelatinization steaming is 105°C, the steaming time is 3 minutes, the temperature of the primary steaming is 95°C, and the steaming time is 10 seconds; and,

[0062] (3) The primary noodles are blown and shredded. The temperature of the blown shreds is 28° C. and the wind ...

Embodiment 3

[0070] The invention provides a kind of instant potato noodles, and the dosage of each raw material is: 75g of whole potato powder, 40g of wheat flour, 10g of gluten powder and peanut protein powder in total.

[0071] The production process includes the following steps:

[0072] (1) 75g of whole potato powder, 40g of wheat flour, 10g of gluten powder and peanut protein powder are mixed altogether, add 10g of water, grind, make the fineness of mixed powder less than 120 orders;

[0073] (2) Adding water equivalent to 35g of the weight of the mixed powder into the mixed powder, followed by gelatinization steaming, primary steaming and secondary extrusion to obtain primary noodles, wherein the temperature of the gelatinization steaming is 95°C, the steaming time is 3 minutes, the temperature of the primary steaming is 80°C, and the steaming time is 10 seconds; and,

[0074] (3) The primary noodles are blown and loosened. The temperature for blowing and loosening is 15° C. and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com