Silver nanoparticle-embedded carbon microsphere preparation method

A technology of silver nanoparticles and carbon microspheres, applied in the fields of botanical equipment and methods, chemicals for biological control, animal repellents, etc., can solve the problems of easy shedding, expensive equipment, raw materials, poor dispersibility, etc. To achieve the effect of good powder dispersion, price and non-toxic, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Put 2 g of camellia oleifera husk powder with a particle size of 200 mesh in deionized water and stir and swell at a constant speed for 6 hours. The solid-liquid ratio of camellia oleifera husk powder to water is 2:60 (g / mL).

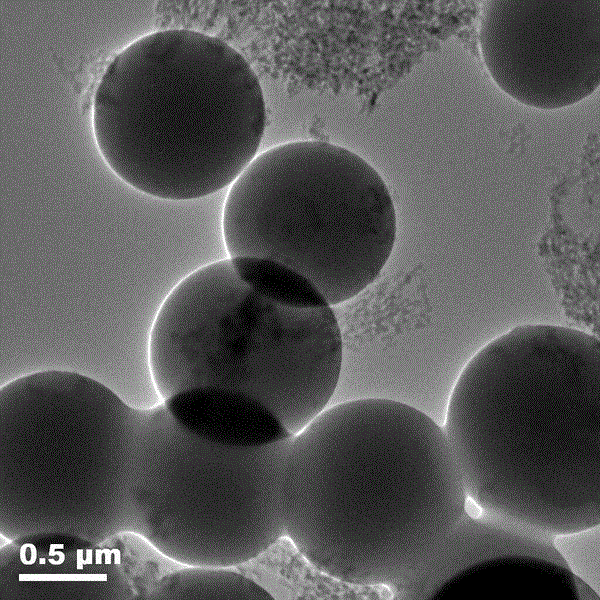

[0028] 2) Put the Camellia oleifera husk powder treated in 1) in a stainless steel reaction kettle with a polytetrafluoroethylene liner, react in an oven at 230°C for 12 hours, cool naturally to room temperature, separate the obtained solids, and wash them with deionized water, After washing with ethanol for several times and drying, the hydrothermal carbon microspheres of camellia oleifera shell were obtained.

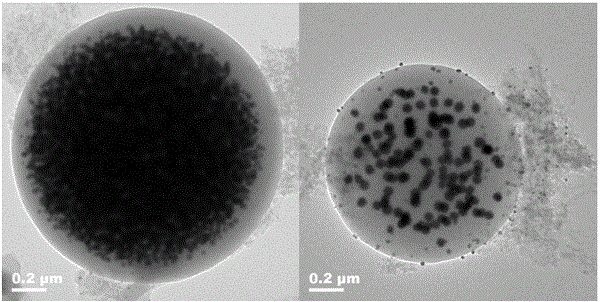

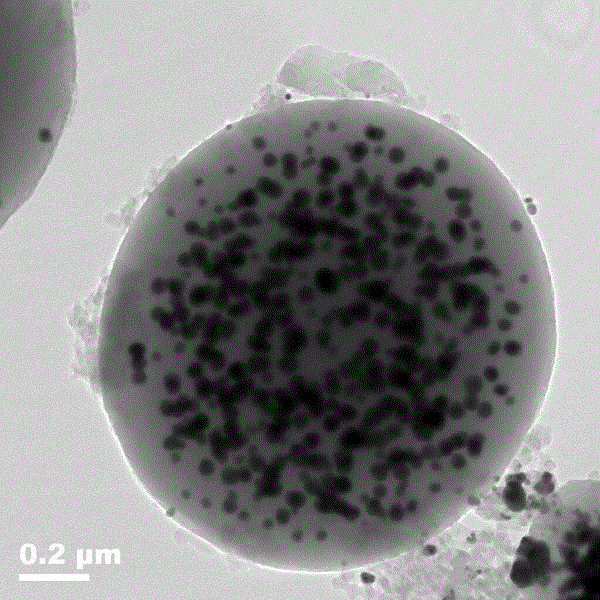

[0029] 3) Take 0.2 g of hydrothermal carbon microspheres obtained in 2) and disperse them in 30 mL of silver nitrate ethanol solution with a concentration of 5 mmol / L, and vibrate on a constant temperature shaker for 12 h under dark conditions.

[0030] 4) Put the solid-liquid mixture in 3) into a polytetrafluoroethylene-lined stainle...

Embodiment 2

[0034] 1) Put 2 g of camellia oleifera husk powder with a particle size of 200 mesh in deionized water and stir and swell at a constant speed for 6 hours. The solid-liquid ratio of camellia oleifera husk powder to water is 2:60 (g / mL).

[0035] 2) Put the Camellia oleifera husk powder treated in 1) in a stainless steel reaction kettle with a polytetrafluoroethylene liner, react in an oven at 230°C for 12 hours, cool naturally to room temperature, separate the obtained solids, and wash them with deionized water, After washing with ethanol for several times and drying, the hydrothermal carbon microspheres of camellia oleifera shell were obtained.

[0036] 3) Take 0.2 g of hydrothermal carbon microspheres obtained in 2) and disperse them in 30 mL of silver nitrate ethanol solution with a concentration of 5 mmol / L, and vibrate on a constant temperature shaker for 12 h under dark conditions.

[0037] 4) Put the solid-liquid mixture in 3) into a polytetrafluoroethylene-lined stainle...

Embodiment 3

[0040] 1) Put 2 g of camellia oleifera husk powder with a particle size of 200 mesh in deionized water and stir and swell at a constant speed for 6 hours. The solid-liquid ratio of camellia oleifera husk powder to water is 2:60 (g / mL).

[0041] 2) Put the Camellia oleifera husk powder treated in 1) in a stainless steel reaction kettle with a polytetrafluoroethylene liner, react in an oven at 230°C for 12 hours, cool naturally to room temperature, separate the obtained solids, and wash them with deionized water, After washing with ethanol for several times and drying, the hydrothermal carbon microspheres of camellia oleifera shell were obtained.

[0042] 3) Take 0.2 g of hydrothermal carbon microspheres obtained in 2) and disperse them in 30 mL of silver nitrate ethanol solution with a concentration of 5 mmol / L, and vibrate on a constant temperature shaker for 12 h under dark conditions.

[0043] 4) Put the solid-liquid mixture in 3) into a polytetrafluoroethylene-lined stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com