Preparation method of antibacterial non-woven fabric

A technology of non-woven fabrics and base fabrics, which is applied in non-woven fabrics, rayon manufacturing, textiles and papermaking, etc. It can solve the problems of insufficient combination of antibacterial active ingredients and matrix fibers, uneven dispersion, etc., and improve hydrophilic performance , Improve compatibility and reduce interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of antibacterial nonwoven fabric, comprises the steps:

[0025] The first step, according to the following parts by weight: 90-100 parts of polyester resin (PET), 8-10 parts of glycidyl methacrylate grafted polyolefin elastomer (GMA-g-POE), 3 parts of modified chitosan - Weigh each raw material in 4 parts;

[0026] The glycidyl methacrylate grafted polyolefin elastomer itself is an elastomer, and the epoxy group of GMA-g-POE reacts with the terminal carboxyl group or terminal hydroxyl group of the PET molecular chain to form a copolymer, which is used as An interfacial modifier improves the compatibility between the matrix and the dispersed phase and reduces the interfacial tension, so it can increase the notched impact strength of the blend; in addition, when the blended material is impacted instantaneously, the The elastomer can instantly absorb most of the impact energy, effectively improving the toughness of PET;

[0027] Modified chit...

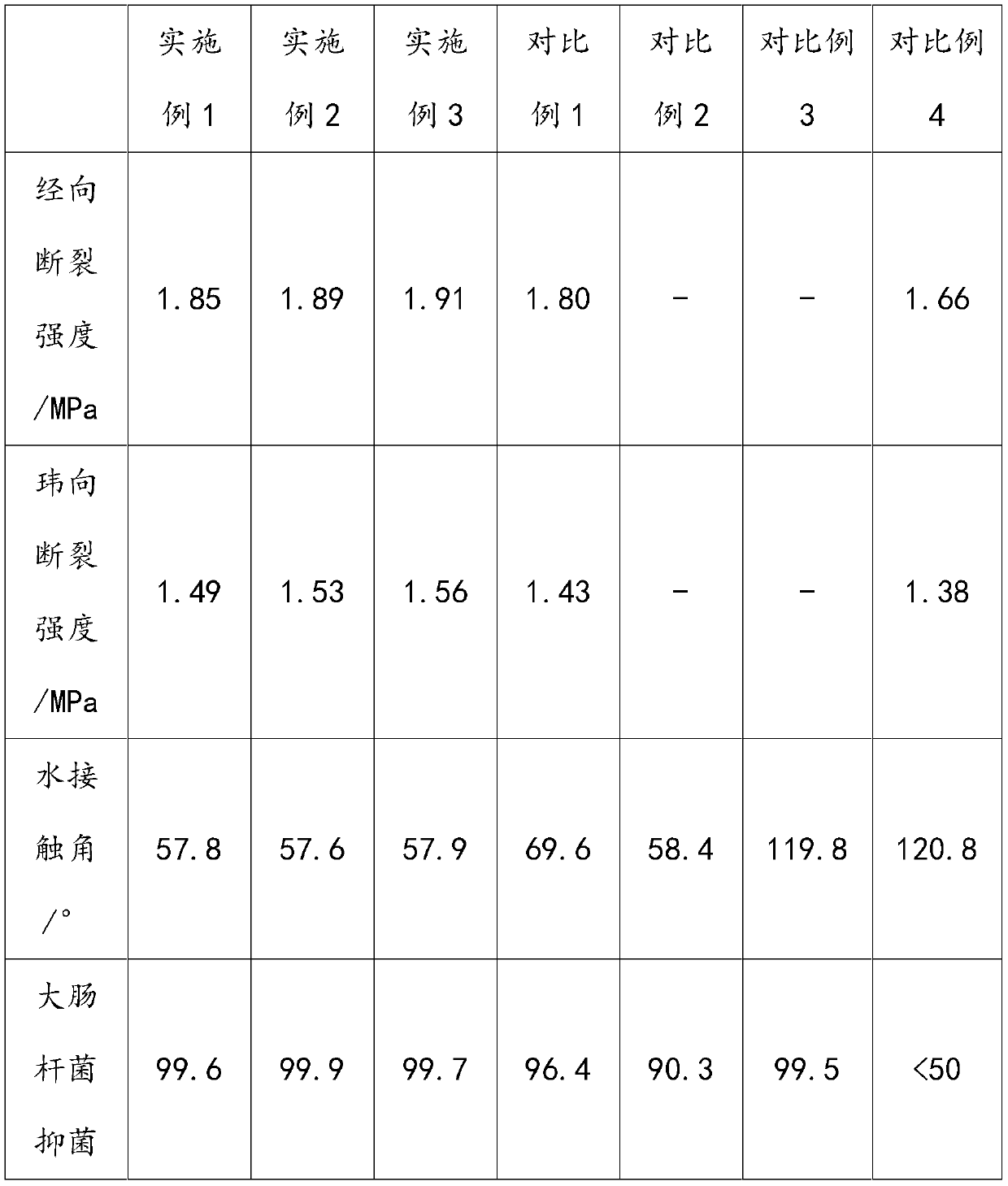

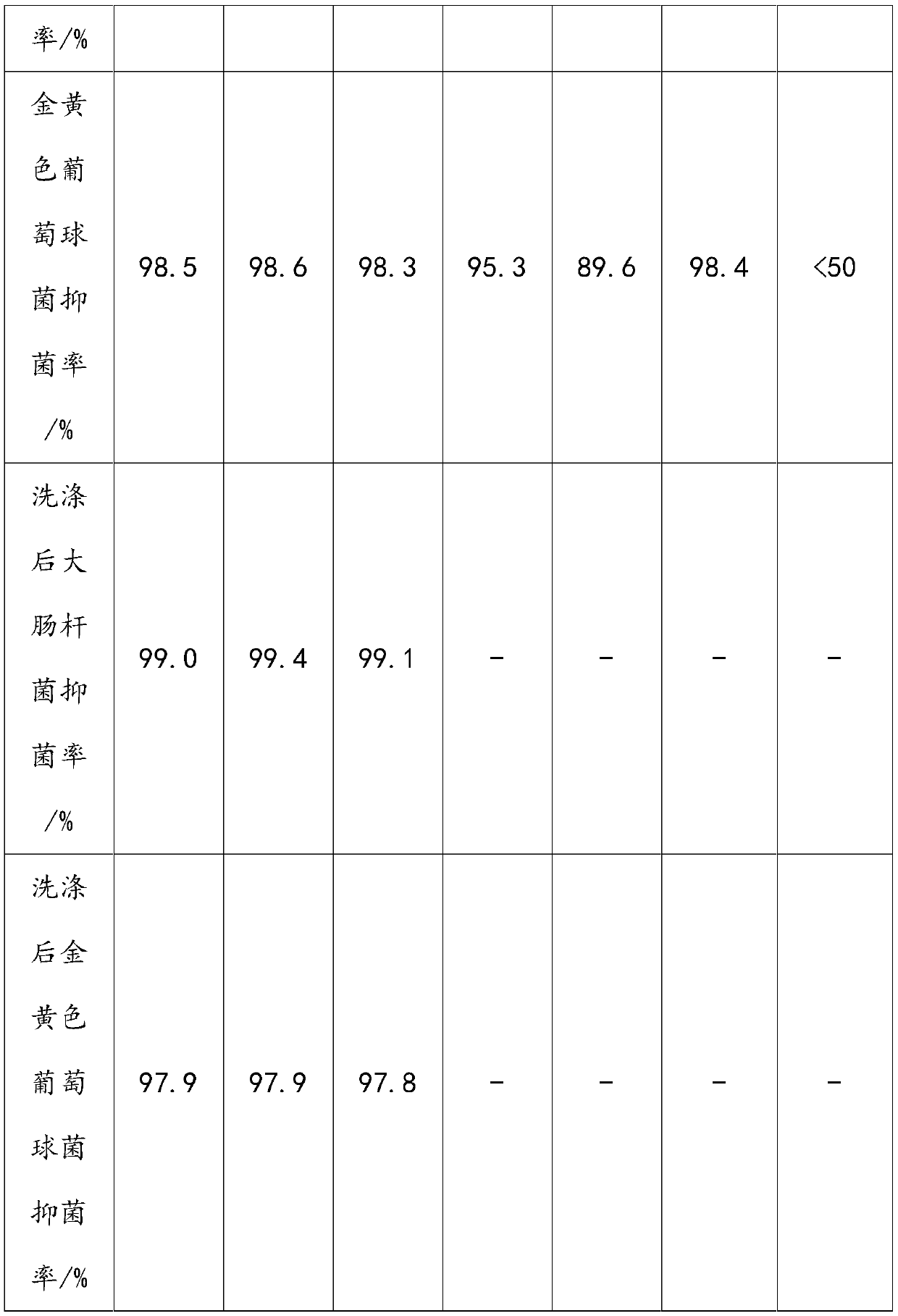

Embodiment 1

[0042] A kind of antibacterial non-woven fabric is made by following steps:

[0043] The first step, according to the following parts by weight: 90 parts of PET, 8 parts of glycidyl methacrylate grafted polyolefin elastomer, 3 parts of modified chitosan and weigh each raw material;

[0044] The second step is to vacuum-dry PET at 120°C until the moisture content is less than 50ppm, and vacuum-dry the modified chitosan at 80°C for 12 hours, then add PET and modified chitosan to a twin-screw extruder for extrusion and granulation , to obtain the copolymer;

[0045] The third step is to dissolve the copolymer in hexafluoroisopropanol, prepare a 200g / L spinning solution, and then perform electrospinning to make a base fabric;

[0046] The fourth step is to put the base fabric in absolute ethanol for 30 minutes, then rinse it with ultrapure water, then immerse it in the ethanol solution of 1,5-pentanediamine, react in a water bath at 55°C for 18 hours, and take it out with an ultr...

Embodiment 2

[0050] A kind of antibacterial non-woven fabric is made by following steps:

[0051] The first step, according to the following parts by weight: 95 parts of PET, 9 parts of glycidyl methacrylate grafted polyolefin elastomer, 3.5 parts of modified chitosan and weigh each raw material;

[0052] The second step is to vacuum-dry PET at 120°C until the moisture content is less than 50ppm, and vacuum-dry the modified chitosan at 80°C for 12 hours, then add PET and modified chitosan to a twin-screw extruder for extrusion and granulation , to obtain the copolymer;

[0053] The third step is to dissolve the copolymer in hexafluoroisopropanol, prepare a 200g / L spinning solution, and then perform electrospinning to make a base fabric;

[0054] The fourth step is to put the base fabric in absolute ethanol for 35 minutes, then rinse it with ultrapure water, then immerse it in the ethanol solution of 1,5-pentanediamine, react it in a water bath at 55°C for 19 hours, and take it out with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com