Preparation method for modified polyamide composite material

A composite material and polyamide technology, which is applied in the field of preparation of modified polyamide composite materials, can solve the problems of poor mechanical properties, poor impact resistance and poor processing properties of the composition, and achieves improved mechanical impact resistance and reduced Water absorption, coefficient of friction, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

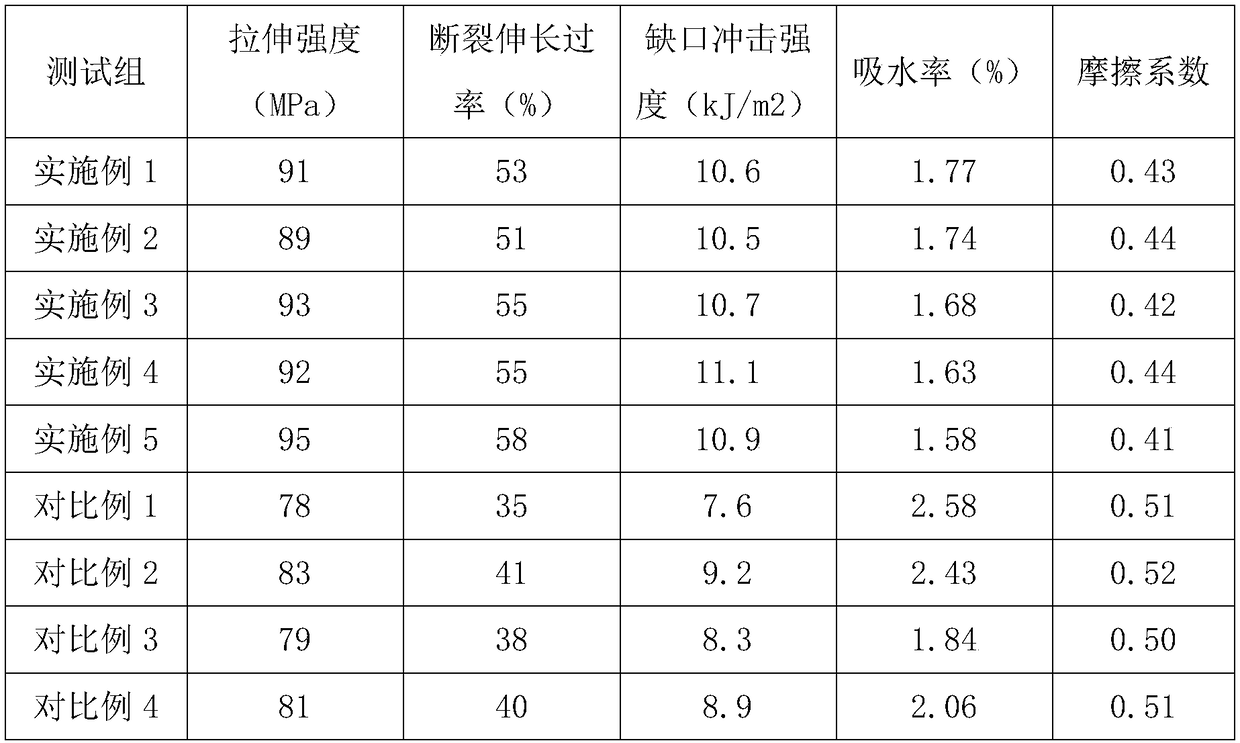

Examples

Embodiment 1

[0030] A preparation method of modified polyamide composite material, comprising the following steps:

[0031] (1) Put an appropriate amount of maleic anhydride and polyphenylene ether into a high-speed mixer and mix for 15 minutes, then add it to a twin-screw extruder, melt and extrude at 275 degrees Celsius to obtain maleic anhydride grafted polyphenylene ether ether;

[0032] (2) Add graphene oxide into deionized water, stir evenly, disperse in an ultrasonic disperser for 15 minutes, prepare a 1 g / ml graphene oxide solution, and add 2,3-epoxy to the graphene aqueous solution Propyltrimethylammonium chloride until no new brown flocs are produced;

[0033] (3) The mixture prepared in step (2) is repeatedly centrifuged and washed until the supernatant does not contain chloride ions, and the filter material is placed in a vacuum drying oven at 80 degrees Celsius to dry to obtain modified graphene oxide;

[0034] (4) Add the maleic anhydride grafted polyphenylene ether prepare...

Embodiment 2

[0046] A preparation method of modified polyamide composite material, comprising the following steps:

[0047] (1) Put an appropriate amount of maleic anhydride and polyphenylene ether into a high-speed mixer and mix for 20 minutes, then add it to a twin-screw extruder, melt and extrude at 295 degrees Celsius to obtain maleic anhydride grafted polyphenylene ether ether;

[0048] (2) Add graphene oxide into deionized water, stir evenly, put it into an ultrasonic disperser and disperse for 25 minutes, prepare a 1 g / ml graphene oxide solution, add 2,3-epoxy to the graphene aqueous solution Propyltrimethylammonium chloride until no new brown flocs are produced;

[0049] (3) The mixture prepared in step (2) is repeatedly centrifuged and washed until the supernatant does not contain chloride ions, and the filter material is placed in a vacuum oven at 90 degrees Celsius to dry to obtain modified graphene oxide;

[0050] (4) Add the maleic anhydride grafted polyphenylene ether prepa...

Embodiment 3

[0062] A preparation method of modified polyamide composite material, comprising the following steps:

[0063] (1) Put an appropriate amount of maleic anhydride and polyphenylene ether into a high-speed mixer and mix for 16 minutes, then add them to a twin-screw extruder, melt and extrude at 285 degrees Celsius to obtain maleic anhydride grafted polyphenylene ether ether;

[0064] (2) Add graphene oxide into deionized water, stir evenly, put it into an ultrasonic disperser and disperse for 22 minutes, prepare a 1 g / ml graphene oxide solution, add 2,3-epoxy to the graphene aqueous solution Propyltrimethylammonium chloride until no new brown flocs are produced;

[0065] (3) The mixture prepared in step (2) is repeatedly centrifuged and washed until the supernatant does not contain chloride ions, and the filter material is placed in a vacuum oven at 86 degrees Celsius for drying to obtain modified graphene oxide;

[0066] (4) Add the maleic anhydride grafted polyphenylene ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com