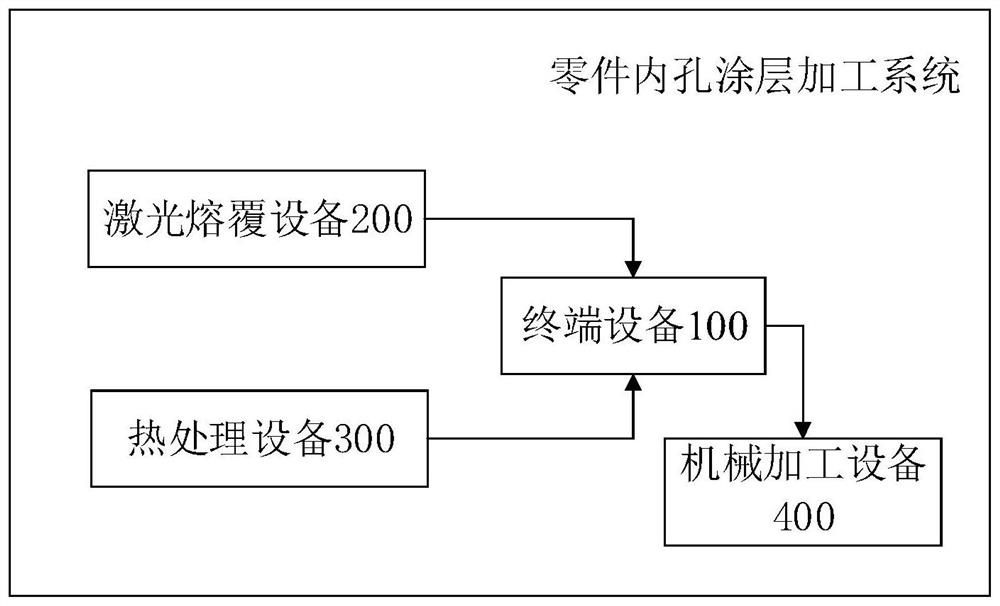

Part inner hole coating machining method and system, and device

A processing method and coating technology, which is applied in the coating process and coating of metal materials, can solve the problems of poor stability of the coating process, easy cracks, holes, and easy deformation of parts, so as to reduce the deformation or even cracking of parts. risk, prevent the coating of parts from falling off, and increase the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, an additive manufacturing part (material: SUS306 stainless steel) is selected as the prefabricated part with a hole structure. The coating powder is made of Stellite 6 cobalt-based alloy. Such as Figure 6 Shown, the concrete implementation process of the present invention is as follows:

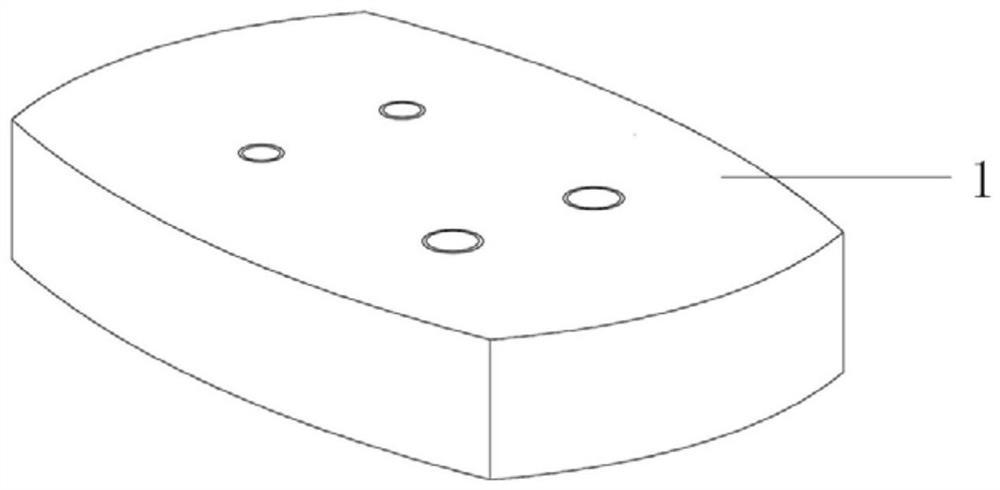

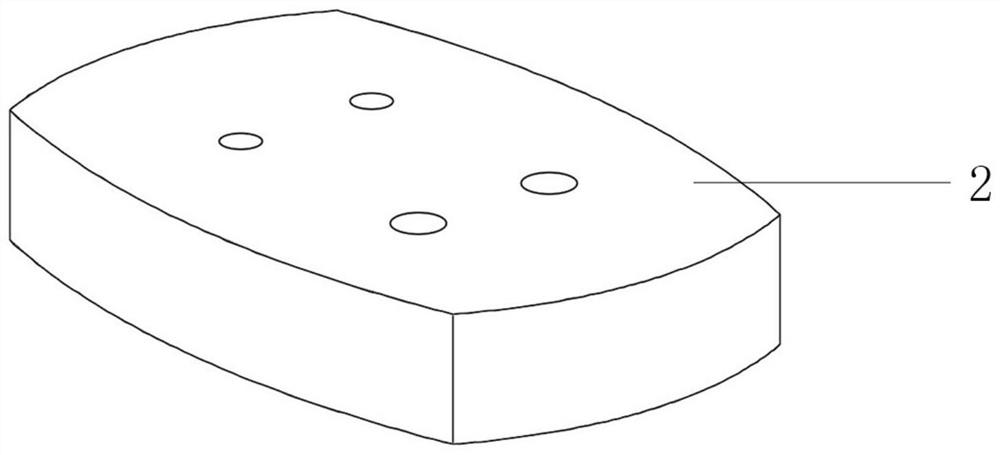

[0057] Step S1: providing a preform with a hole structure.

[0058]Step S2: Take the axis perpendicular to the plane where the hole structure is located passing through the center of the hole structure of the prefabricated part as the center line, and use a hand-held angle grinder to grind out a two-sided symmetrical conical structure at the position of the inner hole of the base material of the part, The diameter of the smallest part of the two-sided symmetrical opposite-top conical structure should not be smaller than the aperture of the prefabricated part with the hole structure.

[0059] Step S3: Use alcohol to remove the oil stain on the surface of the poli...

Embodiment 2

[0068] In this embodiment, an additive manufacturing part (material: SUS306 stainless steel) is selected as the prefabricated part with a hole structure. The coating powder is made of Stellite 6 cobalt-based alloy. Concrete implementation process of the present invention is as follows:

[0069] Step S1: providing a preform with a hole structure.

[0070] Step S2: Taking the axis perpendicular to the plane where the hole structure is located passing through the center of the hole structure of the prefabricated part as the center line, use a hand-held angle grinder to grind a single-sided conical structure at the position of the inner hole of the base material of the part. The diameter of the smallest part of the tapered structure should not be smaller than the hole diameter of the prefabricated part with the hole structure.

[0071] Step S3: Use alcohol to remove the oil stain on the surface of the polished preform with a pore structure, and use mechanical processing equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com