Antenna oscillator and manufacturing method thereof

A manufacturing method and vibrator technology, applied to antennas, antenna parts, antenna supports/installation devices, etc., can solve problems such as directional deviation and failure to meet antenna performance requirements, and achieve the effect of enhancing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. However, those skilled in the art know that the present invention is not limited to the drawings and the following embodiments.

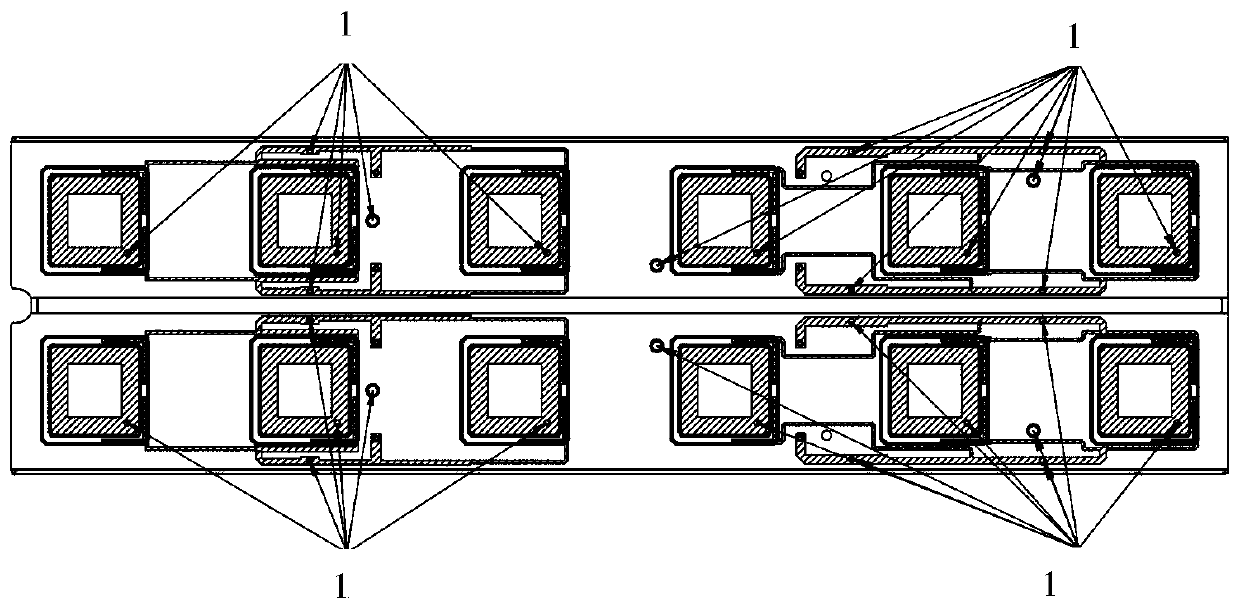

[0069] Such as figure 1 , set multiple rack plating holes 1 in the metal plating area. The rack plating holes are set on a wider network. The current balance must be considered. The rack plating holes should be as far away from the slender network as possible. The recommended diameter of the rack plating holes is 1.6mm. For a large-area plating area, the diameter of the rack plating hole should be appropriately increased, which is 3.1mm in this case.

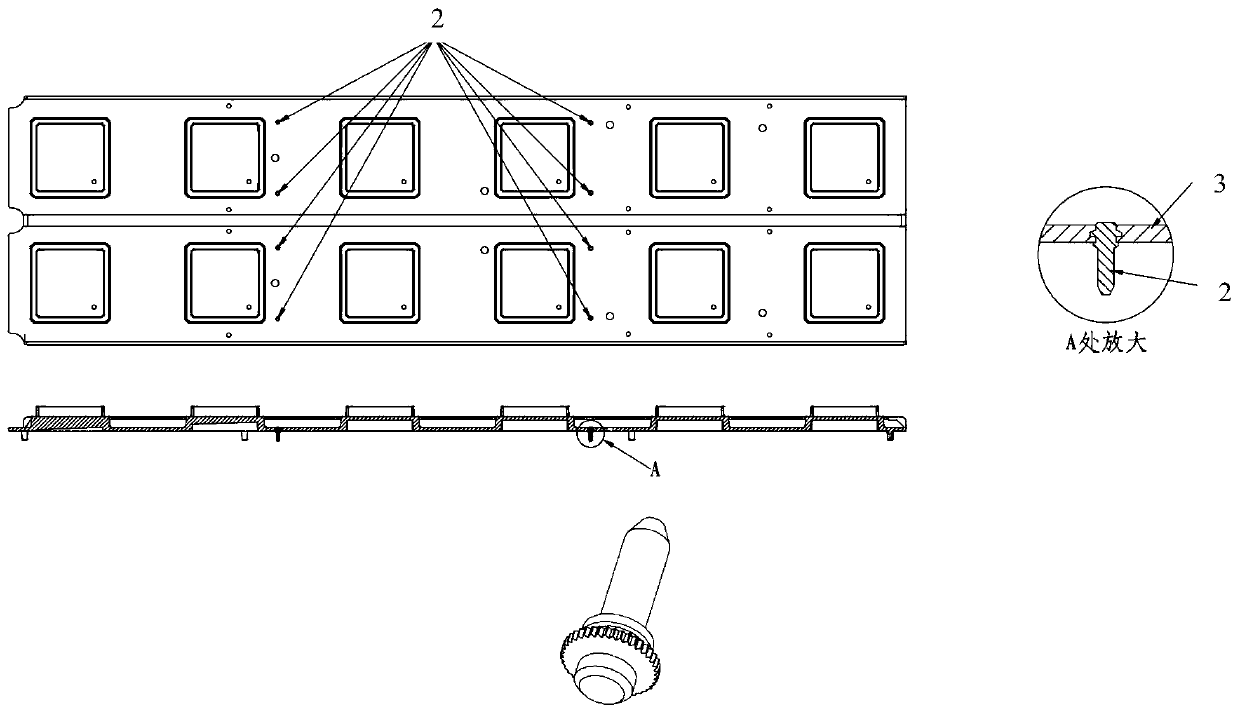

[0070] Such as figure 2 The material of the feeder needle 2 is lead brass, and the head is knurled to increase the bonding force between the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com