Preparation method for composite thermal-insulation brick

A composite thermal insulation and mixed liquid technology, applied in the field of thermal insulation bricks, can solve the problems of low compressive strength, poor weathering resistance, and poor durability of thermal insulation bricks, and achieve the effects of reducing water absorption, increasing water resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

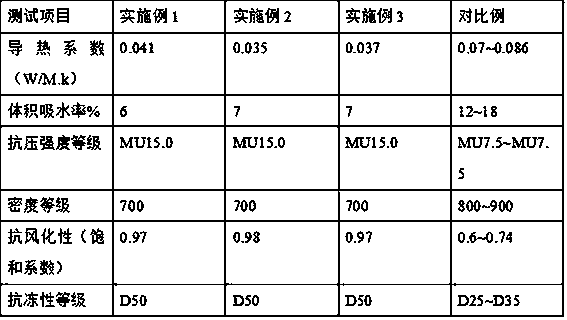

Examples

preparation example Construction

[0022] A preparation method of a composite heat insulating brick, the preparation method comprising the steps of:

[0023] (1) According to the mass ratio of 1:5~7, take the bamboo chips and wheat straw and put them into the pulverizer for 20 minutes at 800r / min, collect the pulverized material, and mix the pulverized material with the mixed solution according to the mass ratio of 4:1~3 Evenly, carry out steam explosion, set the pressure at 1.8~2.3MPa, maintain the pressure for 2~4min, and collect the explosives;

[0024] (2) Freeze-dry the explosives, collect the dry matter, put it into a carbonization furnace, use carbon dioxide for protection, preheat at 130-150°C for 30-50min, then raise the temperature to 180-190°C, carbonize for 2-5h, and collect Carbide, pulverized, passed through a 100-mesh sieve, and collected the sieved particles;

[0025] (3) According to the mass ratio of 4:2:7~10, ultrasonically oscillate the sieved particles, additives and water, let it stand fo...

Embodiment 1

[0029] Preparation of the mixed solution: mix sodium dodecylbenzenesulfonate, ethanol and lactic acid at a mass ratio of 1:6:2.

[0030] Preparation of additives: Mix sodium phytate and sodium pyrophosphate at a mass ratio of 4:1.

[0031] Preparation of mixed particles: Mix aluminum nitrate and calcium chloride at a mass ratio of 1:1.

[0032] Preparation of additives: Mix vinyltrimethoxysilane and maleic anhydride in a mass ratio of 3:5~7.

[0033] A preparation method of a composite heat insulating brick, the preparation method comprising the steps of:

[0034] (1) According to the mass ratio of 1:5, take bamboo chips and wheat straw and put them into the pulverizer for 20 minutes at 800r / min, collect the pulverized material, mix the pulverized material and the mixture evenly at a mass ratio of 4:1, and steam For blasting, set the pressure at 1.8MPa, maintain the pressure for 2 minutes, and collect the explosives;

[0035] (2) Freeze-dry the explosives, collect the dry m...

Embodiment 2

[0040] Preparation of the mixed solution: mix sodium dodecylbenzenesulfonate, ethanol and lactic acid at a mass ratio of 1:9:2.

[0041] Preparation of additives: Mix sodium phytate and sodium pyrophosphate at a mass ratio of 4:1.

[0042] Preparation of mixed particles: Mix aluminum nitrate and calcium chloride at a mass ratio of 1:1.

[0043] Preparation of additives: Mix vinyltrimethoxysilane and maleic anhydride at a mass ratio of 3:7.

[0044] A preparation method of a composite heat insulating brick, the preparation method comprising the steps of:

[0045] (1) According to the mass ratio of 1:7, take bamboo chips and wheat straw and put them into the pulverizer for 20 minutes at 800r / min, collect the pulverized material, mix the pulverized material and the mixture evenly at a mass ratio of 4:3, and steam For blasting, set the pressure at 2.3MPa, maintain the pressure for 4 minutes, and collect the explosives;

[0046] (2) Freeze-dry the explosives, collect the dry matte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com