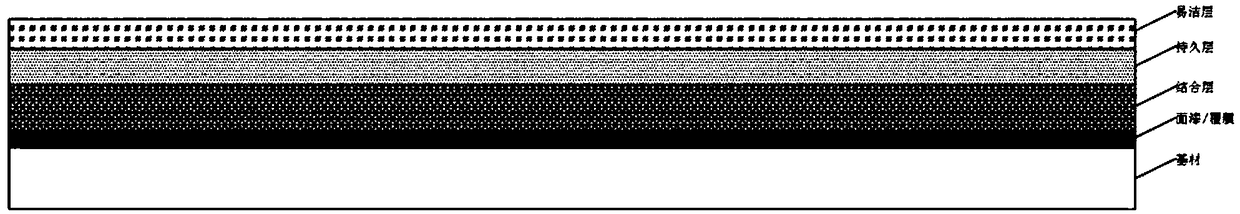

Composition for preparing oil-proof and easy-to-clean paint, related paint, paint preparation method and cupboard board preparation method

A composition and oil-repellent technology, used in anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of poor waterproof and oil-repellent effect and durability, reduced coating surface energy, easy to fall off, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of oil-proof and easy-to-clean coating:

[0059] Weigh butyl acetate, cyclohexanone and n-butanol in a mass ratio of 7:2:1, and mix them uniformly to obtain a mixed solvent; mix fluorine-containing acrylate (12% fluorine content) with According to the mass ratio of 1:1, it was dissolved in the mixed solvent prepared above, and the resin raw material was configured to obtain a mass concentration of 15%; the silicon dioxide particles with a particle diameter of 15nm were added to ethanol and passed through fluorosilane (ten Trifluorooctyltriethoxysilane) was subjected to ultrasonic dispersion and reaction treatment for 4h, after centrifugation, drying, and drying, 3 parts of nano-silica particles after fluorination modification were added to the above-mentioned configured 100 The mass concentration of one part is 15% in the resin raw material, carries out the ultrasonic dispersion of 40min, obtains the nanoparticle modified resin solution; With 1 part of ultra...

Embodiment 2

[0063] Preparation of oil-proof and easy-to-clean coating:

[0064] Weigh butyl acetate, cyclohexanone and n-butanol in a mass ratio of 6:2:2, and mix them uniformly to obtain a mixed solvent; Polyether resin is modified) and acrylate are dissolved in the mixed solvent prepared above according to the mass ratio of 7:3, and configuration obtains the resin raw material that mass concentration is 25%; The silicon dioxide particle that particle diameter is 50nm Add it to ethanol and carry out ultrasonic dispersion and reaction treatment with fluorosilane (tridecafluorooctyltriethoxysilane) for 4 hours. After centrifugation, drying, and drying, the fluorinated modified nano-silica particles Take 4 parts and add them to 100 parts of the above-mentioned resin raw materials with a mass concentration of 25% and perform ultrasonic dispersion for 40 minutes to obtain a nanoparticle modified resin solution; 1 part of UV-326, 1.2 parts of the attached Focusing accelerator polyether modifi...

Embodiment 3

[0068]Preparation of oil-proof and easy-to-clean coating:

[0069] Weigh butyl acetate, cyclohexanone and n-butanol in a mass ratio of 6:2.5:1.5, and mix them uniformly to obtain a mixed solvent; Polyether resin is modified) and acrylate are dissolved in the mixed solvent prepared above according to the mass ratio of 6:4, and configuration obtains the resin raw material that mass concentration is 20%; The silicon dioxide particle that particle diameter is 25nm Add it into ethanol and carry out ultrasonic dispersion and reaction treatment with fluorosilane (heptadecafluorodecyltrimethoxysilane) for 4 hours. After centrifugation, drying, and drying, the nano-silica particles modified by fluorination 3 parts were added to 100 parts of the above-mentioned prepared resin raw materials with a mass concentration of 20% for 40 minutes of ultrasonic dispersion to obtain a nanoparticle modified resin solution; 1.2 parts of UV-326, 1 part of adhesion Accelerator polyether modified organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com