Special-shaped panel prepared from thermoplastic plastics filled with mixture of wheat straw fibers and powder coal ash as well as preparation method of special-shaped panel

A thermoplastic and fly ash technology, applied in the field of materials, can solve the problems of aircraft take-off and landing danger, negative impact on environmental protection, environmental pollution, etc., and achieve the effects of enriching raw material sources, eliminating pollution, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

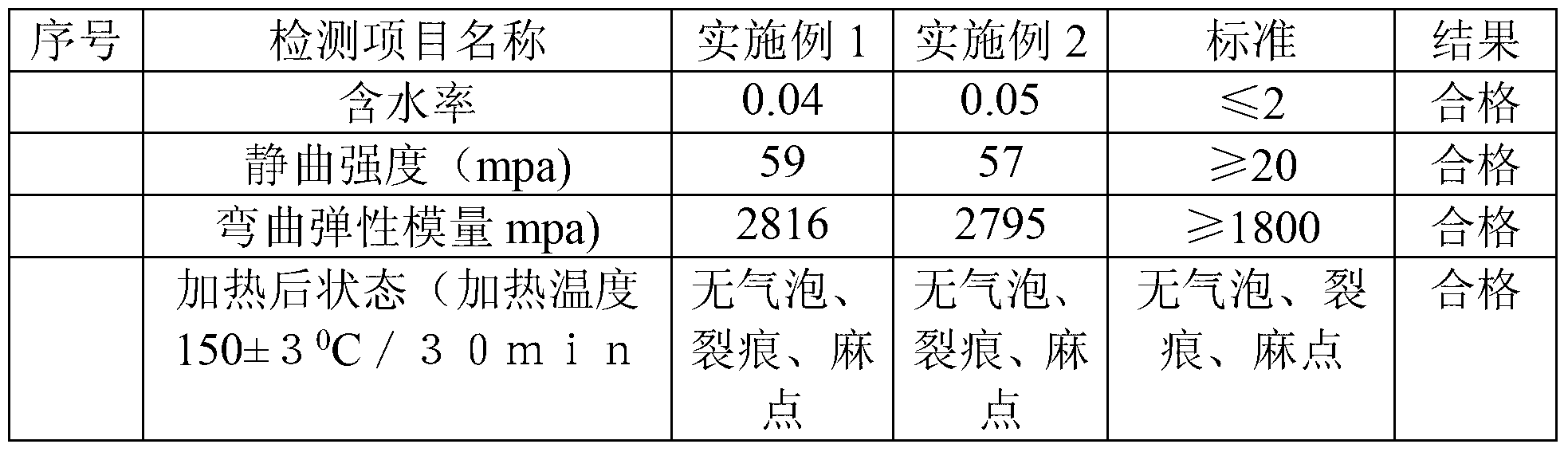

Embodiment 1

[0040] Weigh PVC: 20kg; fly ash: 50kg; wheat straw: 40kg; stabilizer: 6kg; 175S: 4kg; 316 coating agent: 17kg; PE wax: 1kg; stearic acid 1801: 1kg; kg;

[0041]Add 40kg of wheat straw powder, 50kg of coal ash and 17kg of 316 coating agent into the high mixer and mix at a temperature of 60-80°C; then add polymer materials and other auxiliary raw materials and heat-mix at a temperature of 100-130°C; then Vacuum dehumidification, vacuum degree is 0.6 ~ 0.8mPa, cold mixing, granulation into the extruder, the other extruder is rigid PVC, co-extrusion die forming composite special-shaped plate, through co-extrusion die forming, lamination Or spray a wear-resistant layer to make a composite special-shaped plate.

Embodiment 2

[0043] Weigh PS: 75kg; fly ash: 15kg; wheat straw: 30kg; stabilizer: 2kg; 175S: 1kg; 316 coating agent: 5kg; PE wax: 0.5kg; stearic acid 1801: 0.7kg; calcium stearate : 0.3kg; Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com