Method and device for improving permeability and homogeneity of resin and reducing pores of prepreg tape

A technology of prepreg and impregnation, which is applied in the direction of coating, etc., can solve the problems of prepreg performance decline, increase of pore defects, and less amount of fiber impregnated glue, so as to improve the uniformity of resin distribution, reduce pore defects, and improve penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

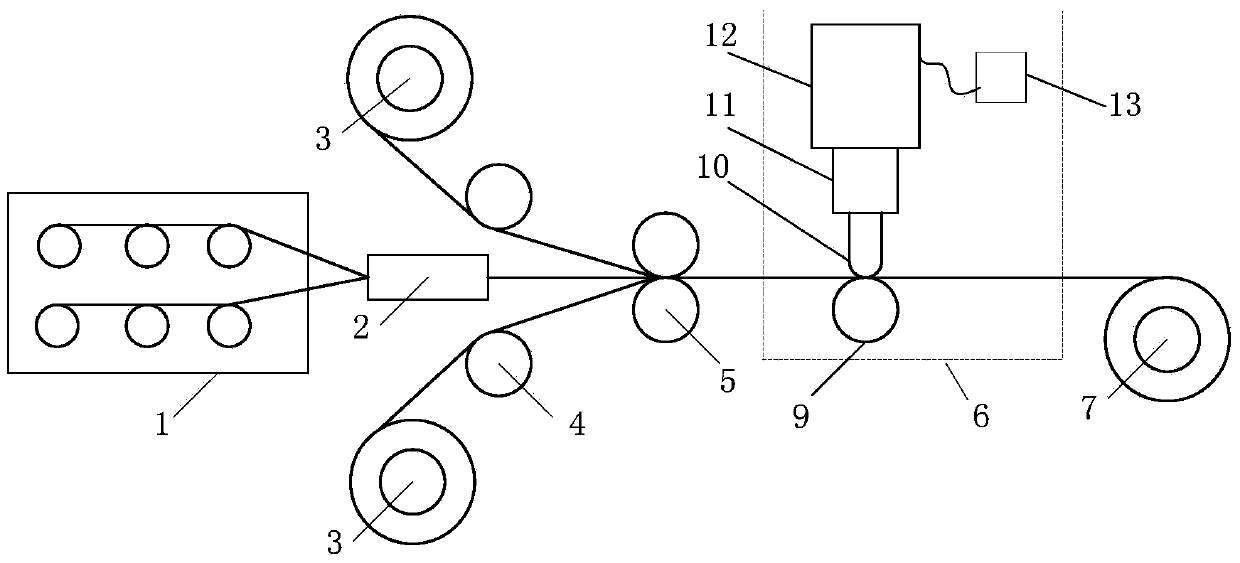

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

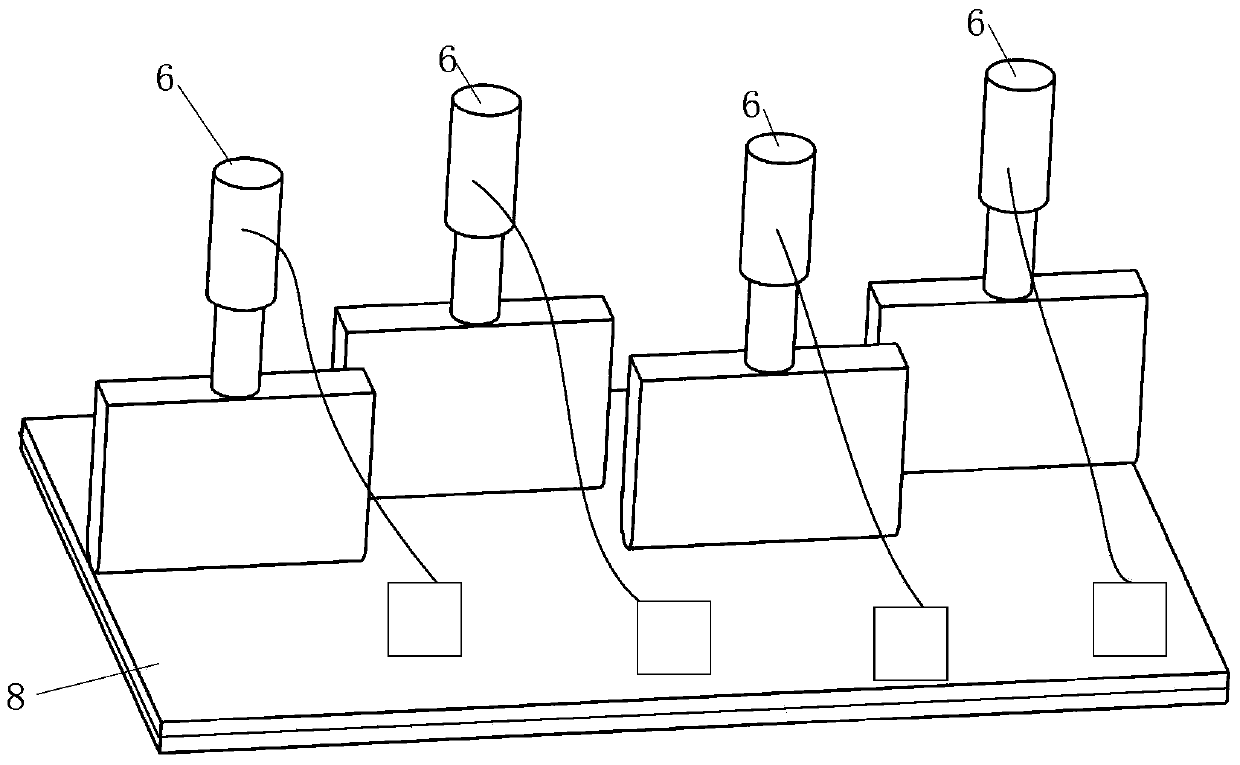

[0023] see figure 1 , the present invention provides a device for improving the penetration and uniformity of the prepreg resin and reducing porosity, including a tow integration device 2 for integrating fiber tows into a prepreg, and the entrance direction of the tow integration device 2 A fiber tow creel 1 for placing fiber tow is arranged on the top, resin film rolls 3 rolled by resin film are arranged on the upper and lower sides of the tow integration device 2, and the exit direction of the tow integration device 2 is sequentially It is equipped with a hot pressing roller 5 for rolling and laminating the integrated prepreg tape and the resin film on its upper and lower sides, and an ultrasonic vibrating roller for ultrasonic vibration auxiliary pressure on the prepreg tape 8 after r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com