Cellular type hollow internal mould plate for building and its wall forming construction method

A kind of internal formwork and partition technology, which is applied in the direction of building structure, building, building components, etc., can solve the problem of not completely solving the stress condition of the outer layer construction and the overall structure of the two sides, and the flatness and strength quality of the wall cannot be obtained. Guarantee, wall structure strength and low shear strength, etc., to achieve the effect of expanding the shotcrete section, light weight and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

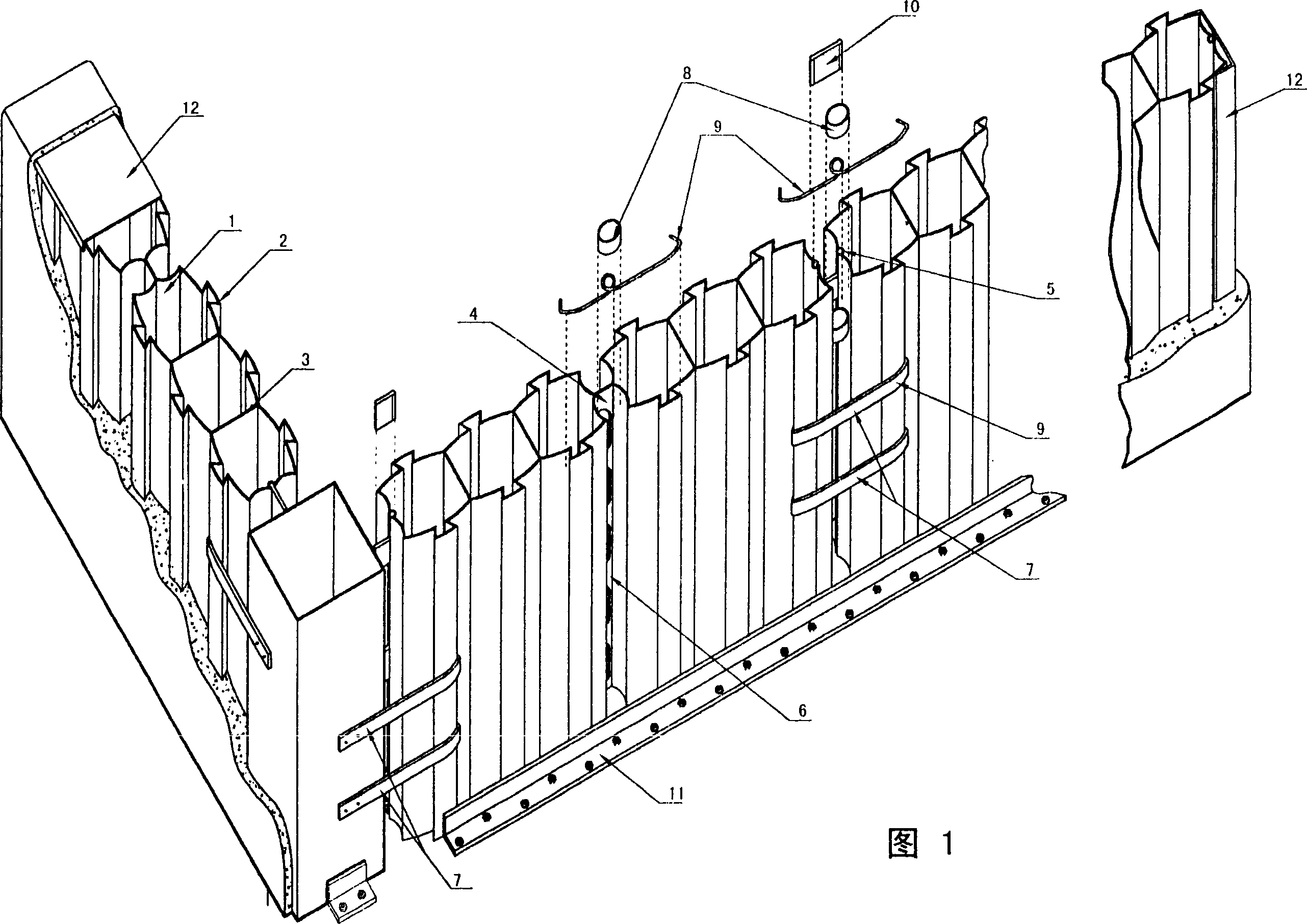

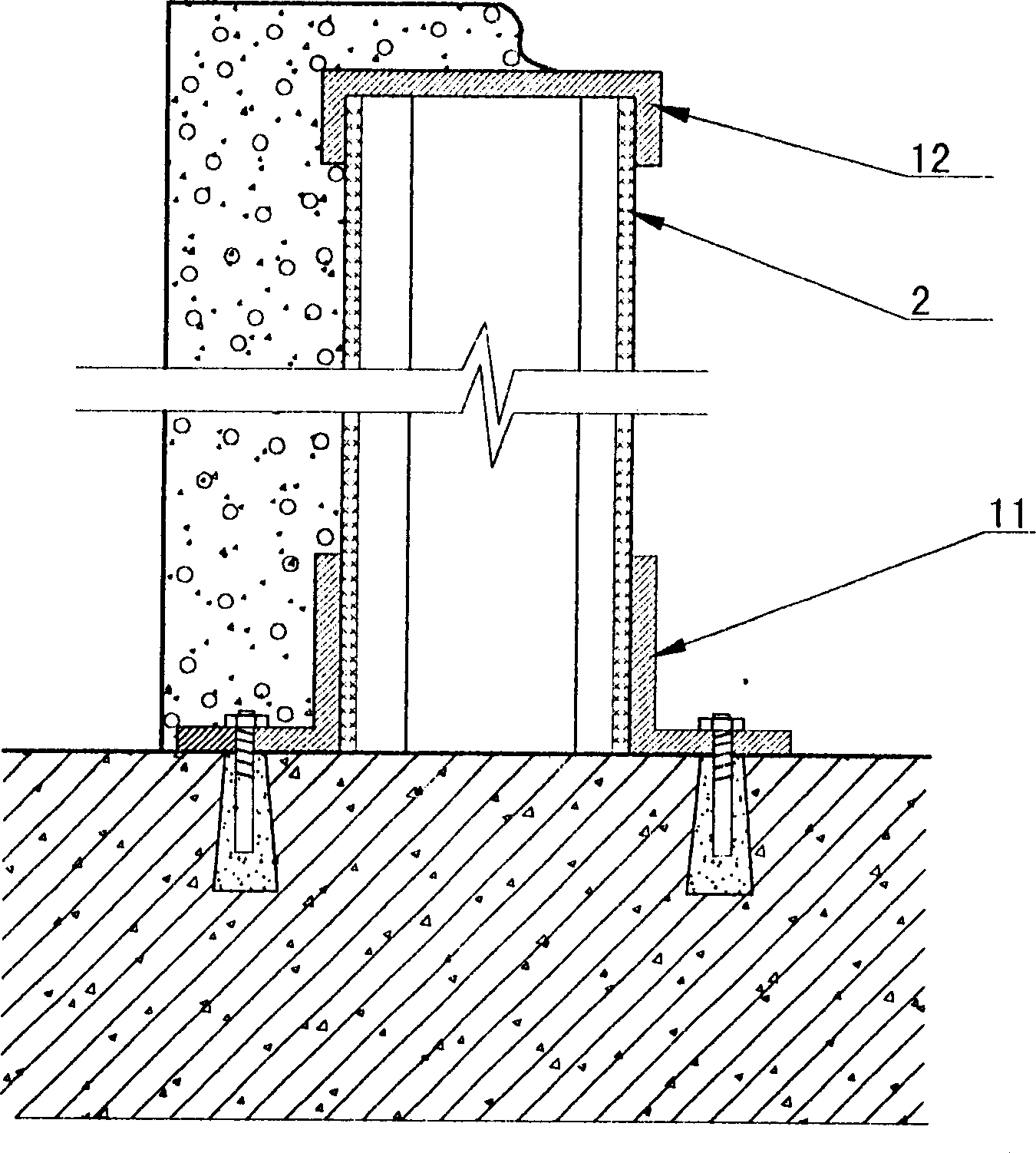

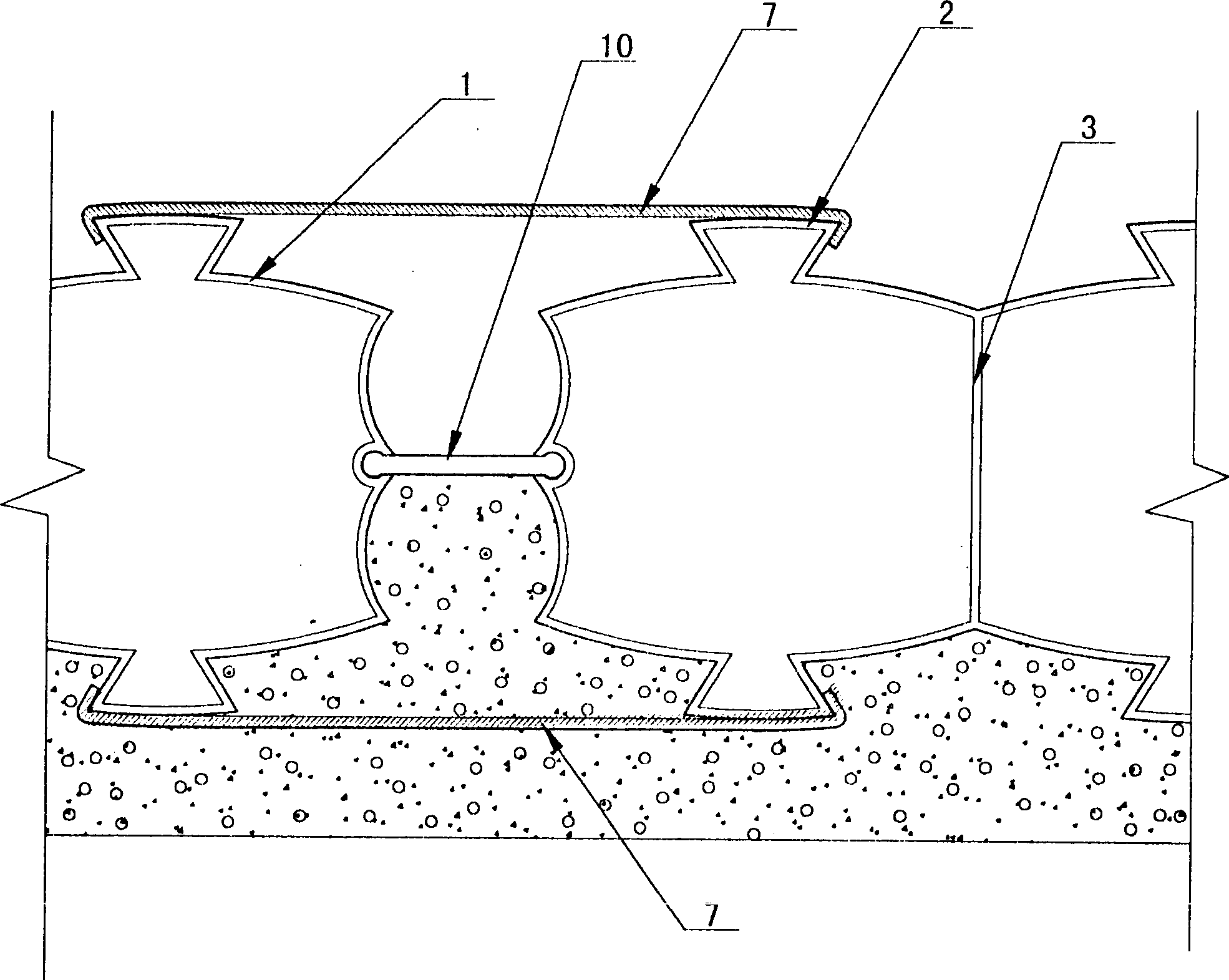

[0034] The partitioned hollow inner formwork for buildings has a simple and compact structure. As shown in Figure 1, the inner formwork is made of plastic or foamed plastic. The two outer surfaces of the inner formwork 1 are provided with bosses 2, and the inner surface is provided with separate support ribs 3. , The inner formwork 1 is provided with a multifunctional groove 4 in the middle, and an extension device 5 is arranged between adjacent inner forms, and the upper and lower sections of the multifunctional groove and the extension device are provided with channels 6 to bond the shotcrete and the inner formwork into a wall . Such as image 3 The bosses 2 on the two outer surfaces of the inner template shown are fixed with fixed spring connecting clips 7 made of metal. Such as Figure 5 As shown in 6, the upper and lower sections of the multifunctional groove 4 are provided with a reinforced tube 8 made of plastic or foamed plastic, and the reinforced tube is positioned by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com