Conveyer belt taking warp-knitted bi-axial fabric as framework and manufacturing method thereof

A biaxial, conveyor belt technology, used in conveyors, chemical instruments and methods, transportation and packaging, etc., can solve the problems of difficult weaving of diameter straight weft skeletons, inability to achieve high elongation force, and difficulty in achieving water quality. Good dimensional stability, response to stress changes, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

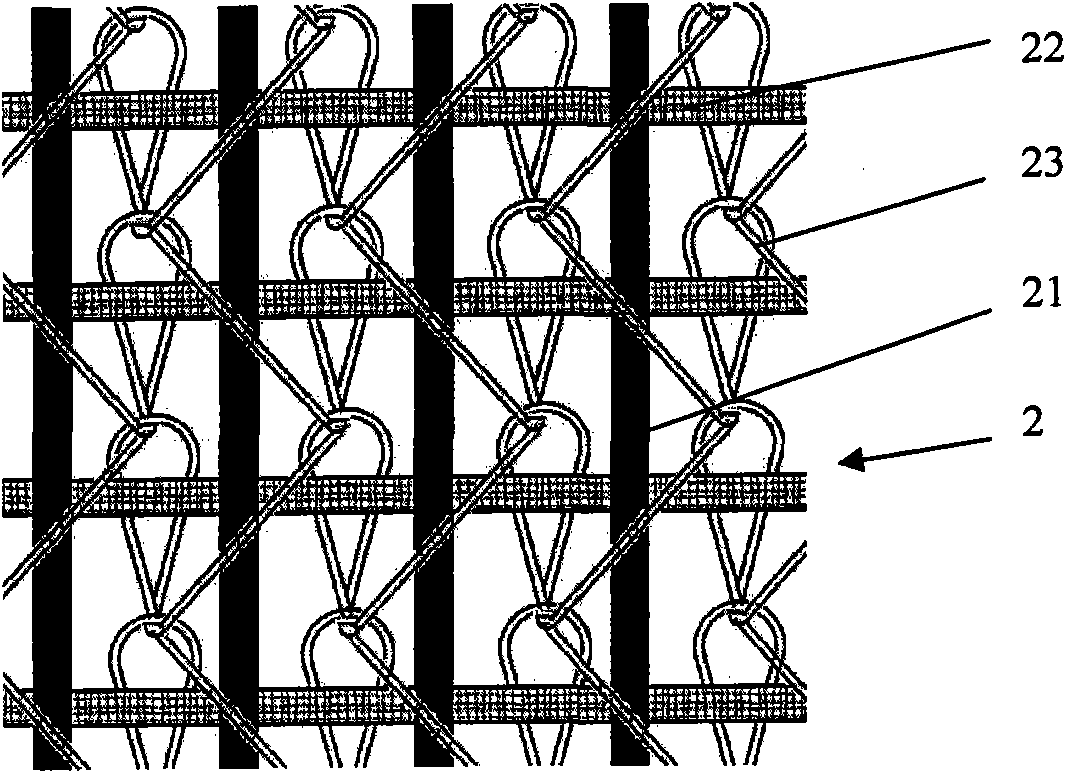

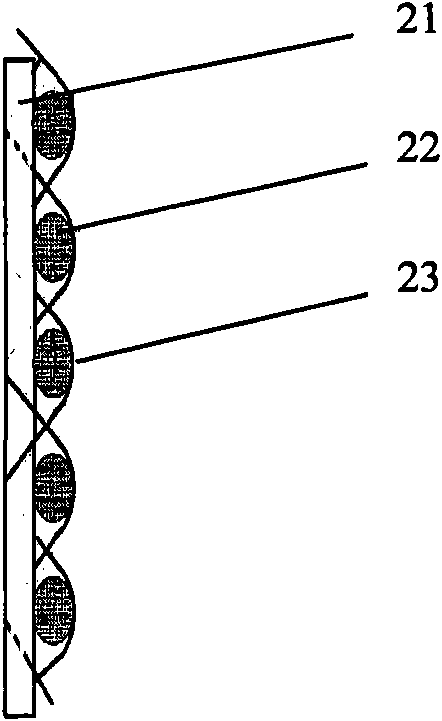

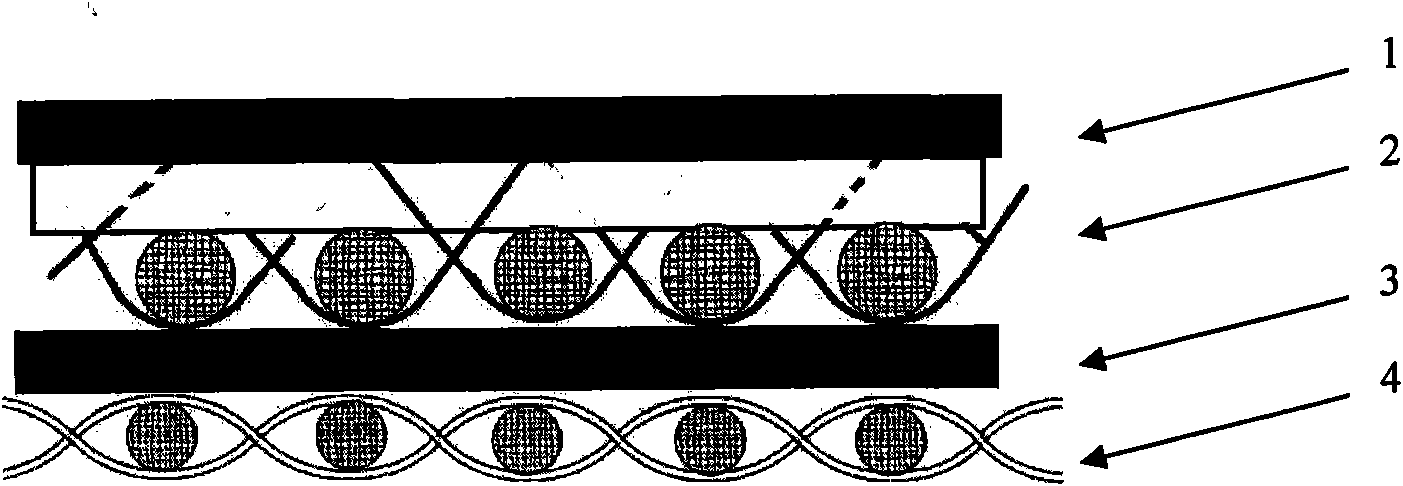

[0048] see image 3 As shown in the schematic cross-sectional structure of the conveyor belt of the present invention, a conveyor belt with a warp-knitted biaxial fabric as the skeleton includes a fabric reinforced skeleton, a covering layer and a covering layer, wherein the reinforced skeleton includes a warp-knitted Biaxial fabric and woven fabric, the conveyor belt is sequentially composed of woven fabric 4, polyvinyl chloride bonding layer 3, warp-knitted biaxial fabric 2 and polyvinyl chloride 1 surface layer from bottom to top.

[0049]In the woven fabric, the weft yarns are polyester monofilaments with a diameter of 0.3 mm to ensure the lateral stability of the conveyor belt, and the weft weaving density is 35 to 40 strands / inch; the warp yarns are polyester monofilaments The yarn has a weaving density of 20-25 strands / inch in the warp direction, and the filament is an ultra-low shrinkage filament with a shrinkage rate of 2.0-3.5%, and its linear density is 950-1500dtex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com