Patents

Literature

51results about How to "Improve extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TPU light conveyor belt for printing and dyeing industry and manufacturing method thereof

InactiveCN102275378AEasy to useBrief contactScreen printersSynthetic resin layered productsSolventWoven fabric

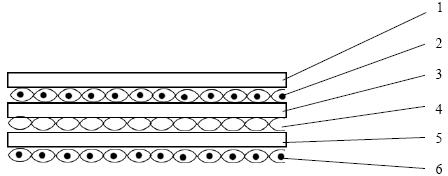

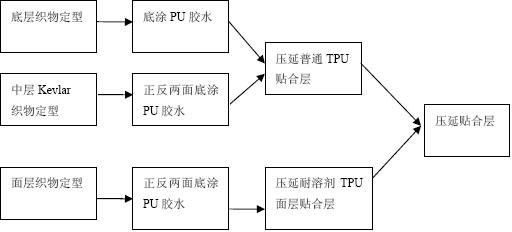

The invention relates to a TPU light-duty conveyor belt used in the printing and dyeing industry and a manufacturing method thereof. The fabric carrier is a three-layer reinforced skeleton, wherein the first and third layer reinforced skeletons are polyester woven fabrics, and the warp yarns are super Low-shrinkage polyester filament, 0.25mm ultra-low-shrinkage polyester monofilament is used in the weft direction, and the second layer of reinforced skeleton is made of Kevlar fiber woven fabric. 3 strands of 21S polyester staple fiber; the cover is made of black TPU polyester material with excellent solvent resistance. The advantages are: the light conveyor belt with this structure not only greatly improves the 1% elongation force, but also has a light body and good flatness, and at the same time achieves high strength and high alignment accuracy; the solvent-resistant TPU surface can be widely used with various cleaning agents, And it can be exposed to acetone and other similar solvents for a short time; the extrusion and calendering process is used to produce the TPU covering layer, which can ensure the compactness of the surface material of the light conveyor belt.

Owner:SHANGHAI YONGLI BELTING +1

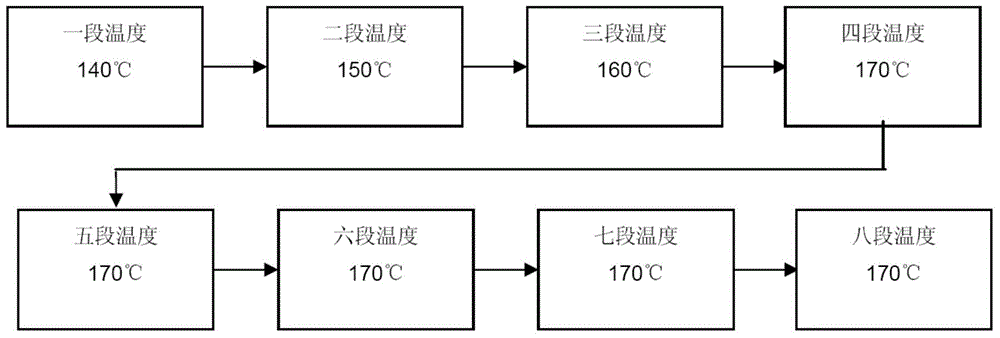

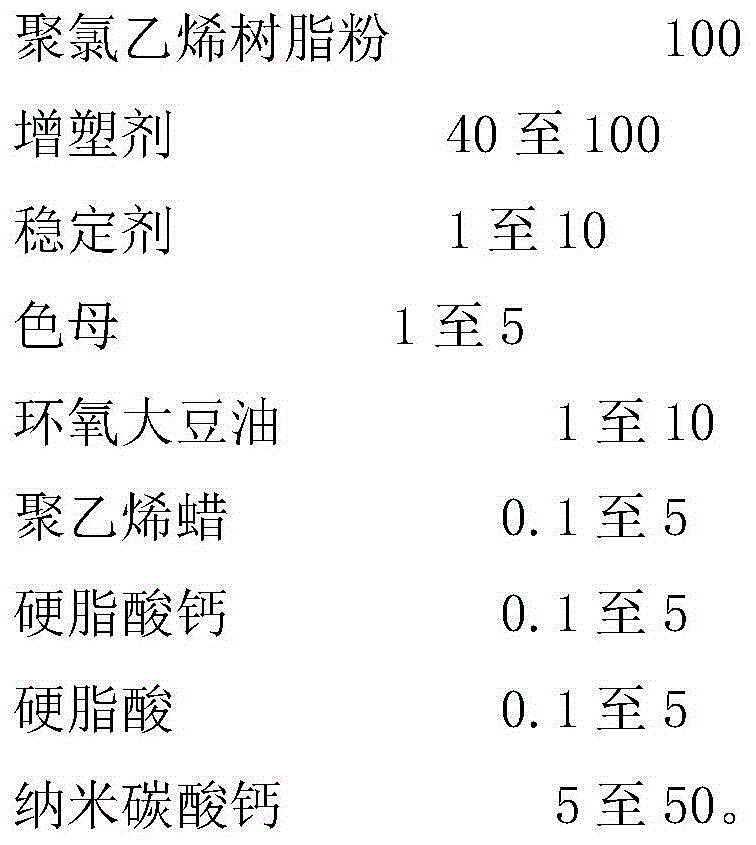

High-density polyvinyl chloride light conveying belt and manufacturing method thereof

ActiveCN105692049AMeet needsHigh strengthConveyorsSynthetic resin layered productsPolyesterHigh density

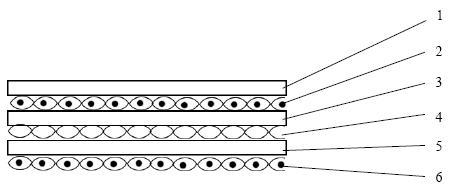

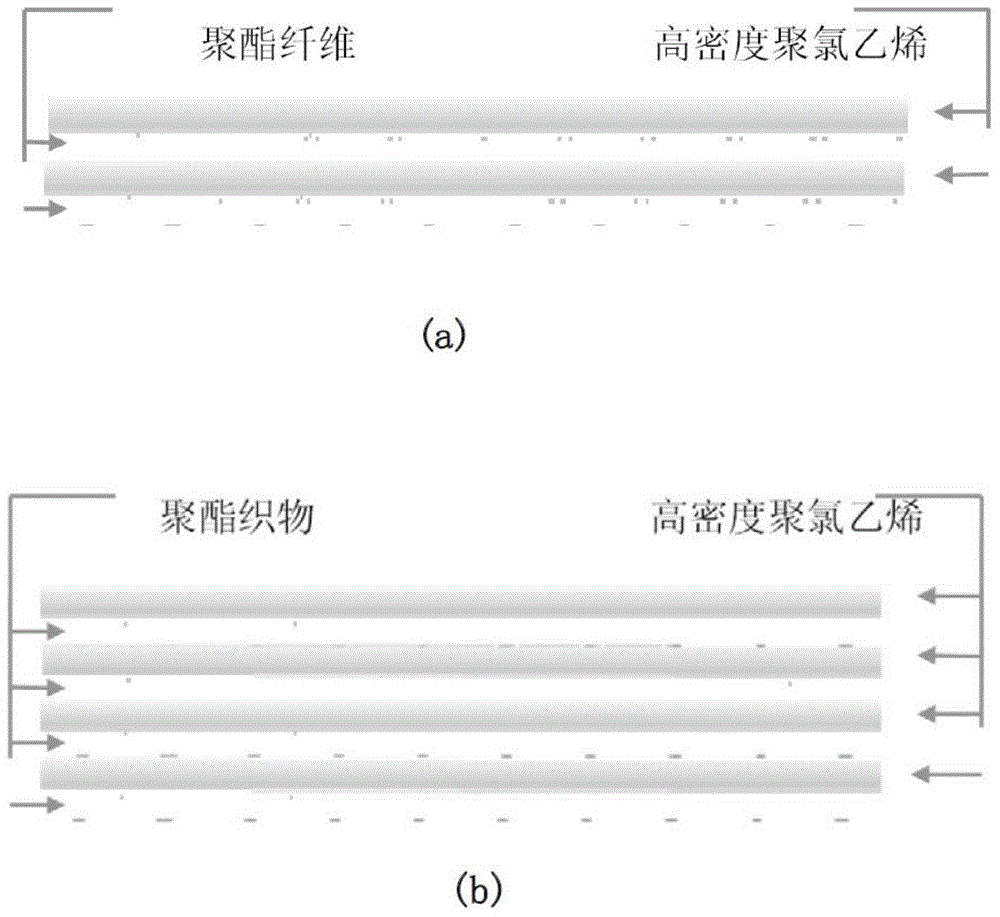

The invention provides a high-density polyvinyl chloride light conveying belt. The high-density polyvinyl chloride light conveying belt comprises a polyester fabric and a high-density polyvinyl chloride covering layer. The polyester fabric serves as a framework material. High-density polyvinyl chloride serves as a surface material and a filling material, and the high-density polyvinyl chloride light conveying belt with the corresponding thickness is obtained. The invention further provides a manufacturing method for the polyvinyl chloride light conveying belt. The high-density polyvinyl chloride light conveying belt obtained through the method has the beneficial effects that the interior is dense, the surface is flat, energy is saved, the tensile strength is high, and the surface is not prone to deformation and also has the beneficial effects that binding between the high-density polyvinyl chloride light conveying belt and the polyester framework material is firm, and the peeling strength is high. The using performance of the conveying belt can be obviously improved, and the service life of the conveying belt can be obviously prolonged; and the work condition of a conveyor can be better improved, the replacing period is prolonged, and the using cost is reduced.

Owner:上海米莜凯自动化装备有限公司

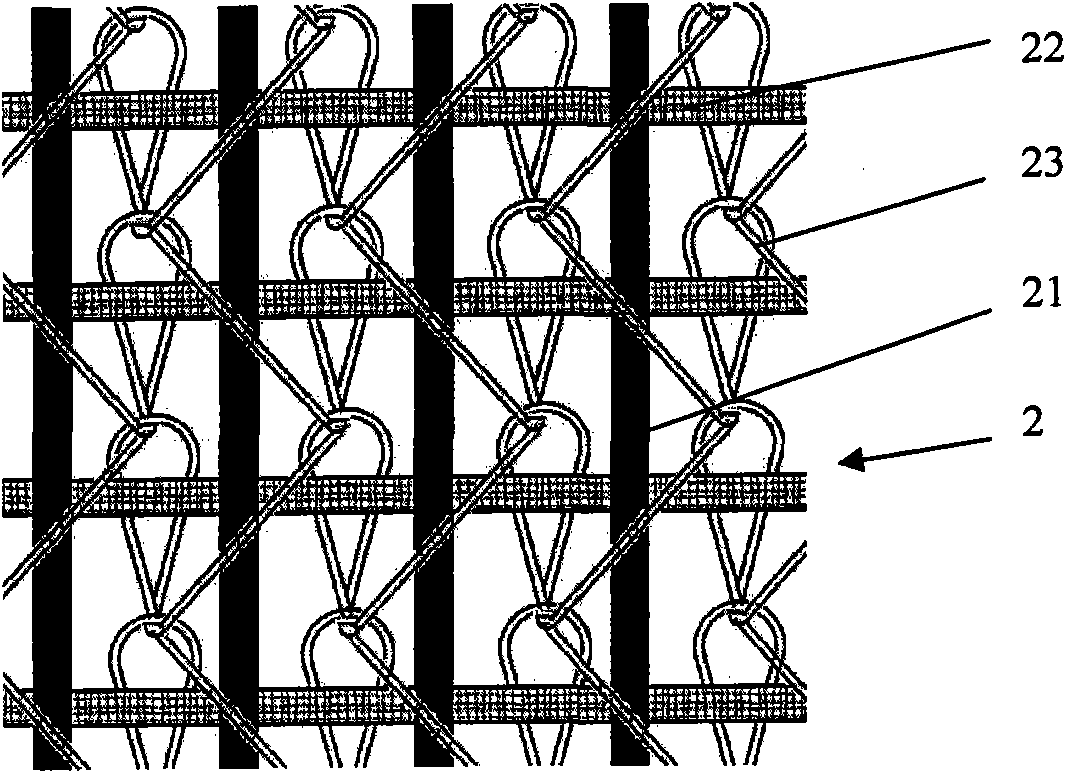

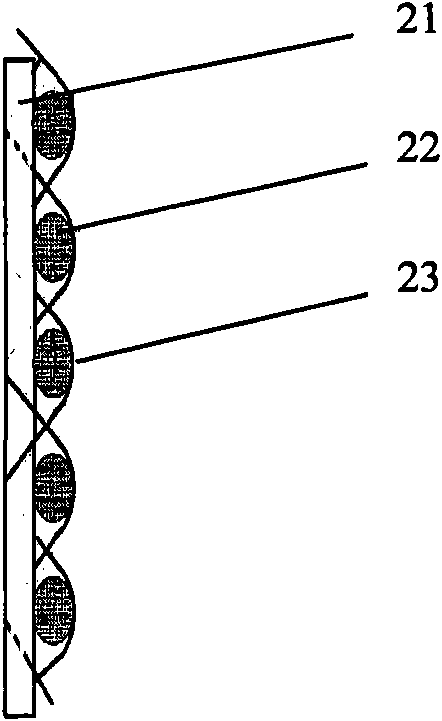

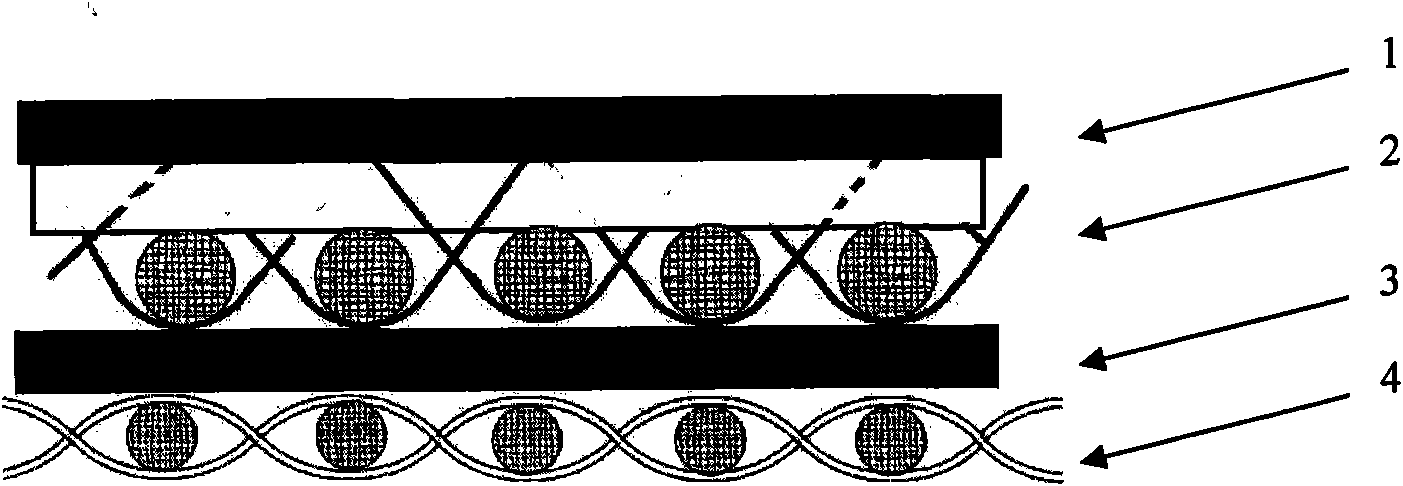

Conveyer belt taking warp-knitted bi-axial fabric as framework and manufacturing method thereof

InactiveCN101830335AHigh strength requirementsThere is no up and down staggered mutual pressure phenomenonConveyorsSynthetic resin layered productsSurface layerPolyvinyl chloride

The invention relates to a conveyer belt taking a warp-knitted bi-axial fabric as a framework and a manufacturing method thereof. The conveyer belt sequentially comprises a woven fabric, a polyvinyl chloride laminated layer, the warp-knitted bi-axial fabric and a polyvinyl chloride surface layer from bottom to top. The manufacturing method comprises the following steps of: finalizing the design of the woven fabric, carrying out primary coat, and coating polyvinyl chloride paste resin to form the laminated layer; finalizing the design of the warp-knitted bi-axial fabric, jointing with the woven fabric of the bottom layer; and carrying out surface layer coating on the warp-knitted bi-axial fabric to form the conveyer belt structure of a double-framework double- polyvinyl chloride layer. The utilization rate of the intensity of warp in the warp-knitted bi-axial fabric reaches the highest, and the warp is always in a straight state and does not have creep relaxation. Self-cementing between the PVC (polyvinyl chloride) surface layer and the PVC laminated layer can be formed, the primary coat process is left out, the racking strength is greatly enhanced, the requirements on roll diameter and tension length of a conveyer are reduced, the service life is improved, and the cost is 40% lower than the woven fabric.

Owner:SHANGHAI YONGLI BELTING +1

Method for preparing welding wire made of nickel base alloy

ActiveCN103949805AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

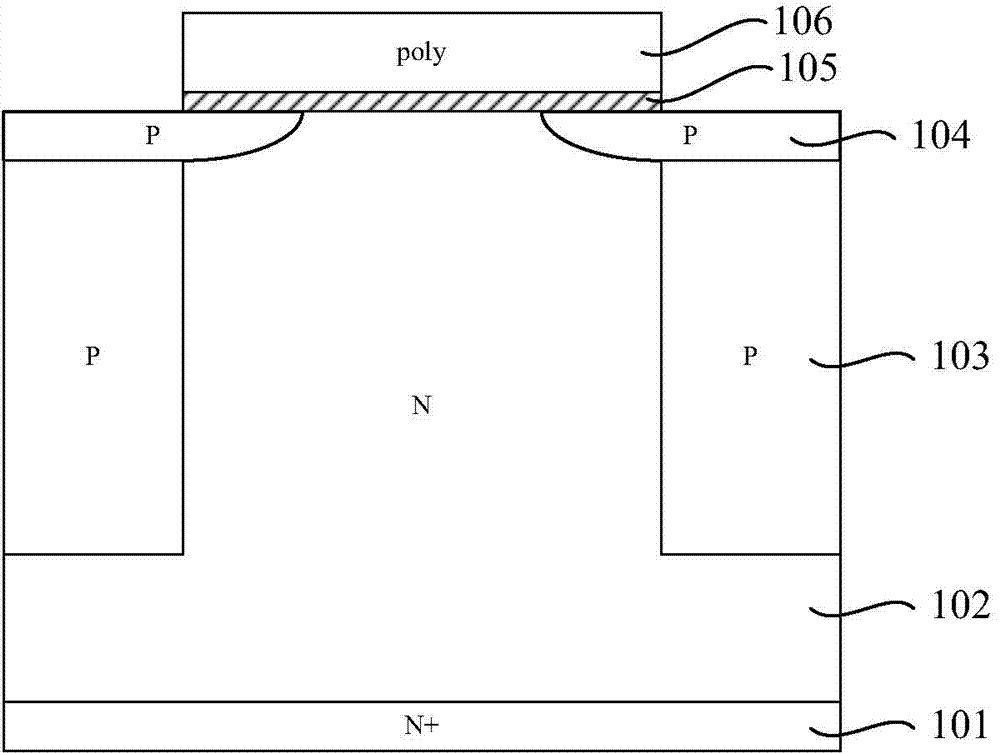

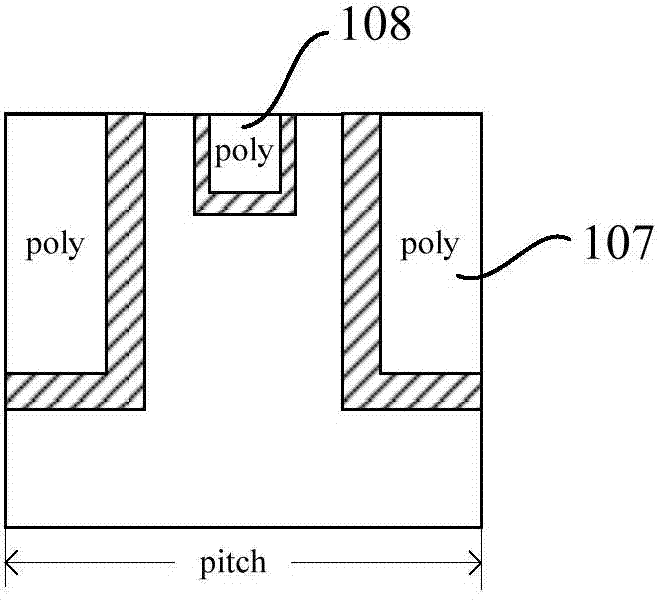

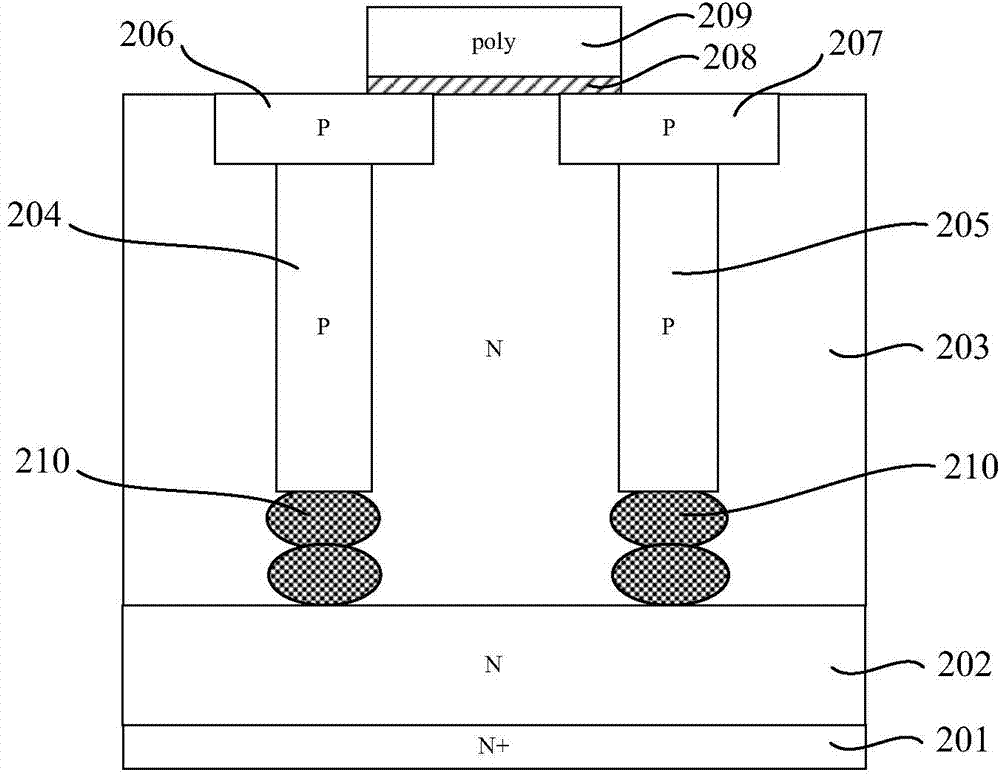

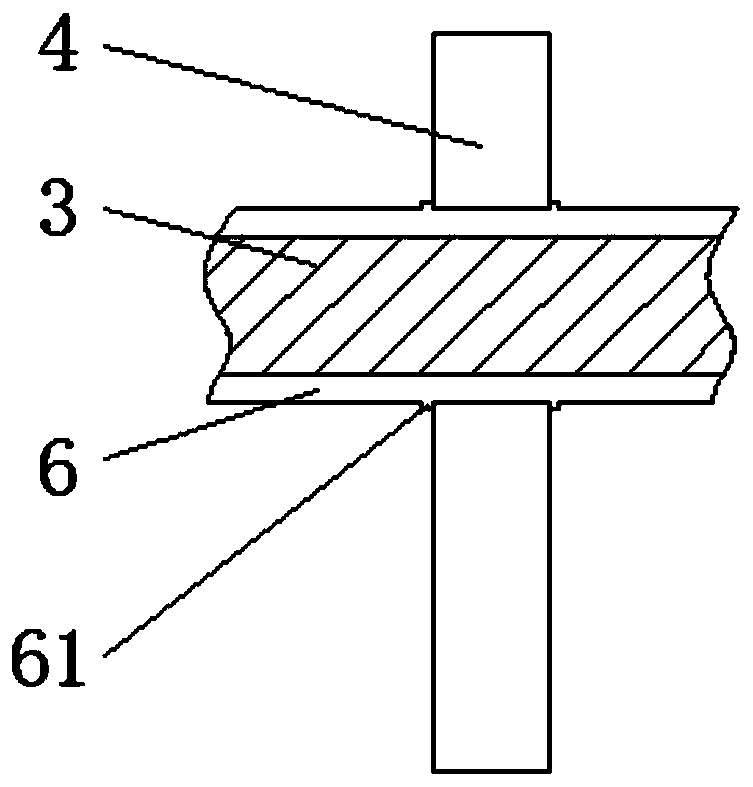

Semi-super-junction MOSFET structure and manufacturing method thereof

ActiveCN104779295AIncrease the withstand voltage rangeAdd depthSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETApplication areas

The invention provides a semi-super-junction MOSFET structure and a manufacturing method thereof. The structure comprises at least one transistor unit. Each transistor unit comprises an N-type heavily doped substrate, an N-type auxiliary layer and an N-type drift layer, wherein the N-type auxiliary layer and the N-type drift layer are sequentially formed on the N-type heavily doped substrate; a first P column and a second P column are formed in the N-type drift layer; the top ends of the first P column and the second P column are connected with a first P-type area and a second P-type area respectively; a grid structure is formed on the surface of the N-type drift layer and located between the first P column and the second P column; the two ends of the grid structure make contact with the first P-type area and the second P-type area respectively; the bottom ends of the first P column and the second P column are each connected with at least one P-island structure located in the N-type drift layer. Due to existence of the P-island structures, the groove depth can be effectively increased, the doping at the bottom of a groove is optimized, and by combining with a bottom auxiliary depletion layer, under the condition of the existing process capacity, the pressure resistance range of a super-junction MOSFET is further enlarged, and the application fields are extended.

Owner:WUXI TONGFANG MICROELECTRONICS

Nickel base alloy welding wire with diameter smaller than 3 mm

ActiveCN103962747AEasy to processHigh strengthWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a nickel base alloy welding wire. Alloy of the nickel base alloy welding wire comprises, by mass, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0.025% or less of P, 0.02% or less of S, 28%-30% of Cr, 49%-51% of Ni, 0.1% or less of Co, 0.1% or less of Mo, 0.1% or less of Ti, 0.1% or less of Al, 4.0%- 5% of W and the balance being Fe. A method for preparing the nickel base alloy welding wire includes the steps of alloy smelting, electroslag remelting, hot forging and blooming, hot rolling and annealing, acid pickling and coping, cold drawing and hydrogen withdrawing. A CaF2 slag system, an Al2O3 slag system and a CaO slag system are adopted in electroslag remelting. Through the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting requirements can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

Method for manufacturing Cr28Ni48W5 nickel base alloy into welding wire

ActiveCN103962756AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a nickel base alloy welding wire. The nickel base alloy comprises, by weight, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0%-0.025% of P, 0%-0.02% of S, 28%-30% of Cr, 49%-51% of Ni, 0%-0.1% of Co, 0%-0.1% of Mo, 0%-0.1% of Ti, 0%-0.1% of Al and 4.0%-5.0% of W, and the balance iron. The preparing method comprises the step of alloy smelting, electroslag remelting, hot forging cogging, hot rolling annealing, acid pickling, coping, cold drawing and hydrogen retreating, and a CaF2, Al2O3 and CaO slag system is adopted in the electroslag remelting. According to the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting the requirement can be obtained, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

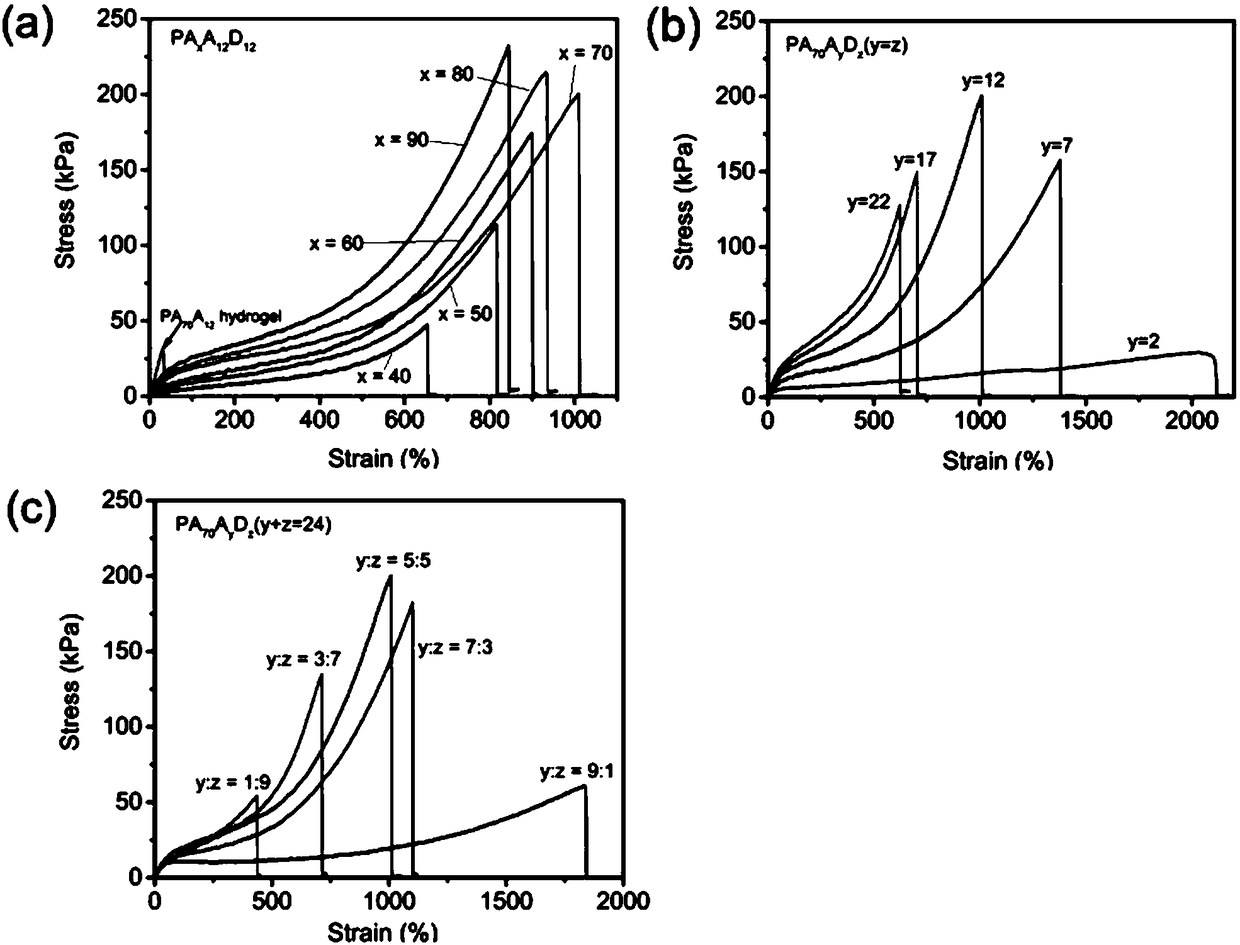

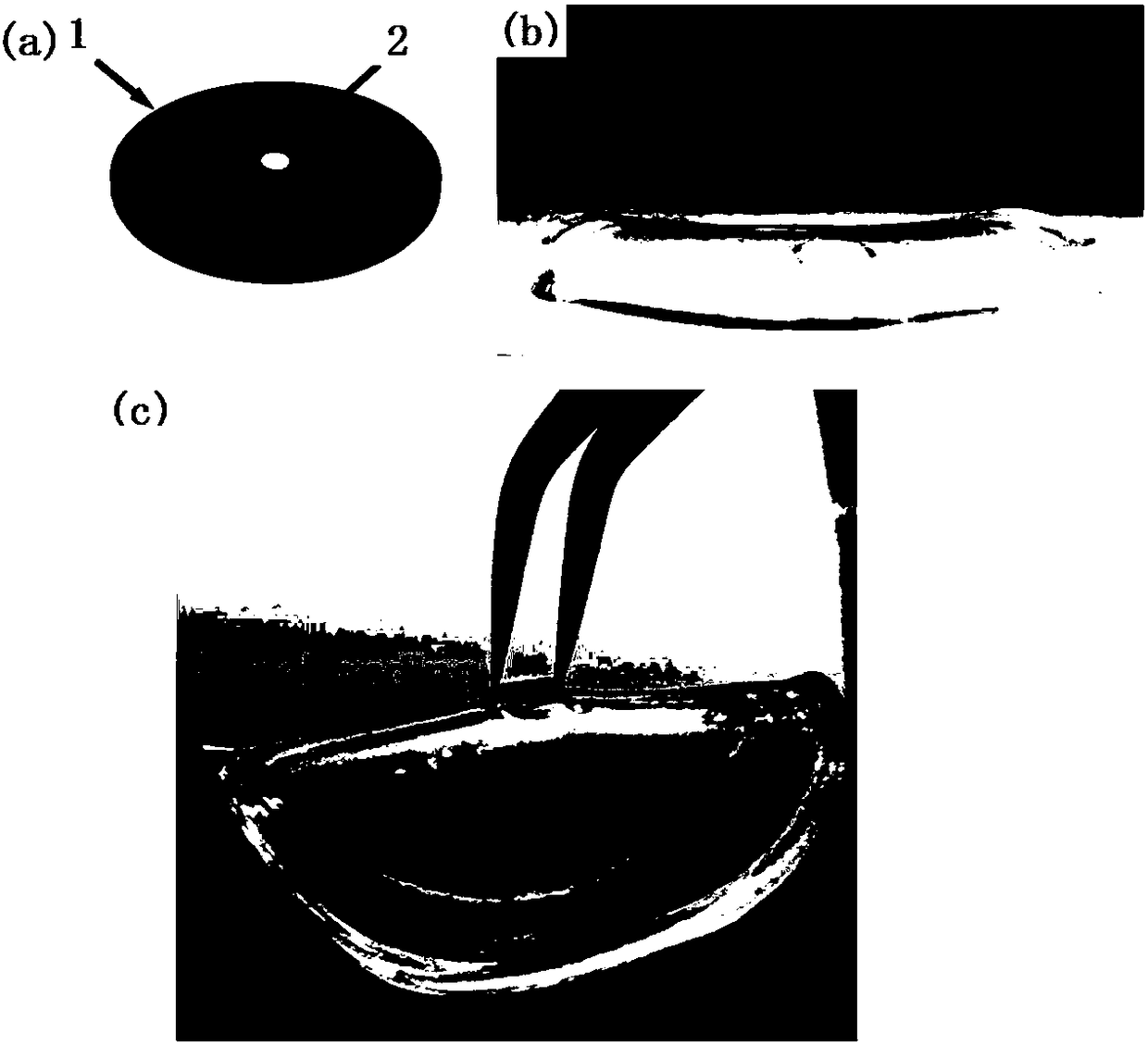

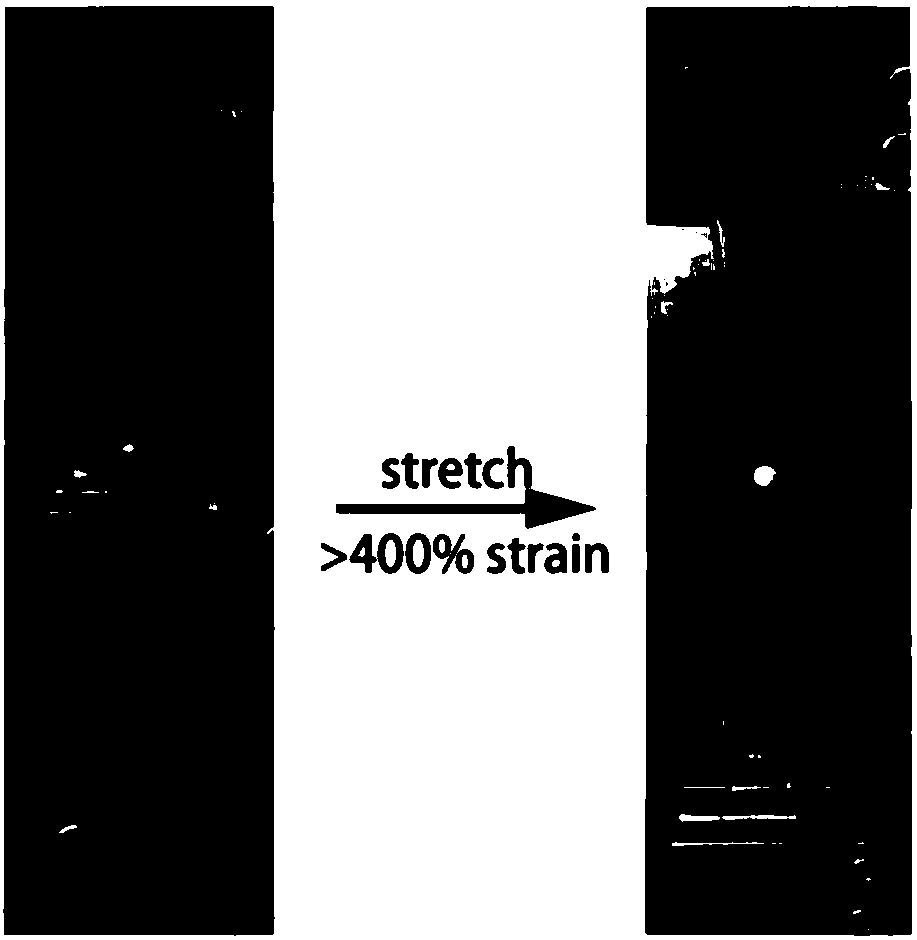

Hydrogel composite device for measuring ionizing radiation dose and preparation method thereof

ActiveCN108276527APreserve radiation dosimetry performanceImprove extensionRadiation measurementX-ray/gamma-ray/particle-irradiation therapyUltraviolet lightsOxygen

The invention relates to a preparation method of a hydrogel composite device for measuring the ionizing radiation dose. The preparation method of the hydrogel composite device for measuring the ionizing radiation dose comprises the following steps: mixing acrylamide, an anionic monomer and a polycationic matrix with a photoinitiator in water to remove oxygen from a mixed solution, then polymerizing by ultraviolet irradiation, and irradiating for 1 to 30 min to obtain a prepolymer; placing a thermoluminescent dosemeter (TLD) on the surface of the prepolymer, and irradiating continuously with ultraviolet light to completely polymerize the prepolymer, thus forming the hydrogel composite device for measuring the ionizing radiation dose. The invention further requires to protect the hydrogel composite device for measuring the ionizing radiation dose prepared by the preparation method. The method disclosed by the invention closely combines hydrogel with excellent mechanical properties and adhesion properties with the TLD, so that the device can be closely adhered to the surface of skin to accurately measure the ionizing radiation dose.

Owner:SUZHOU UNIV

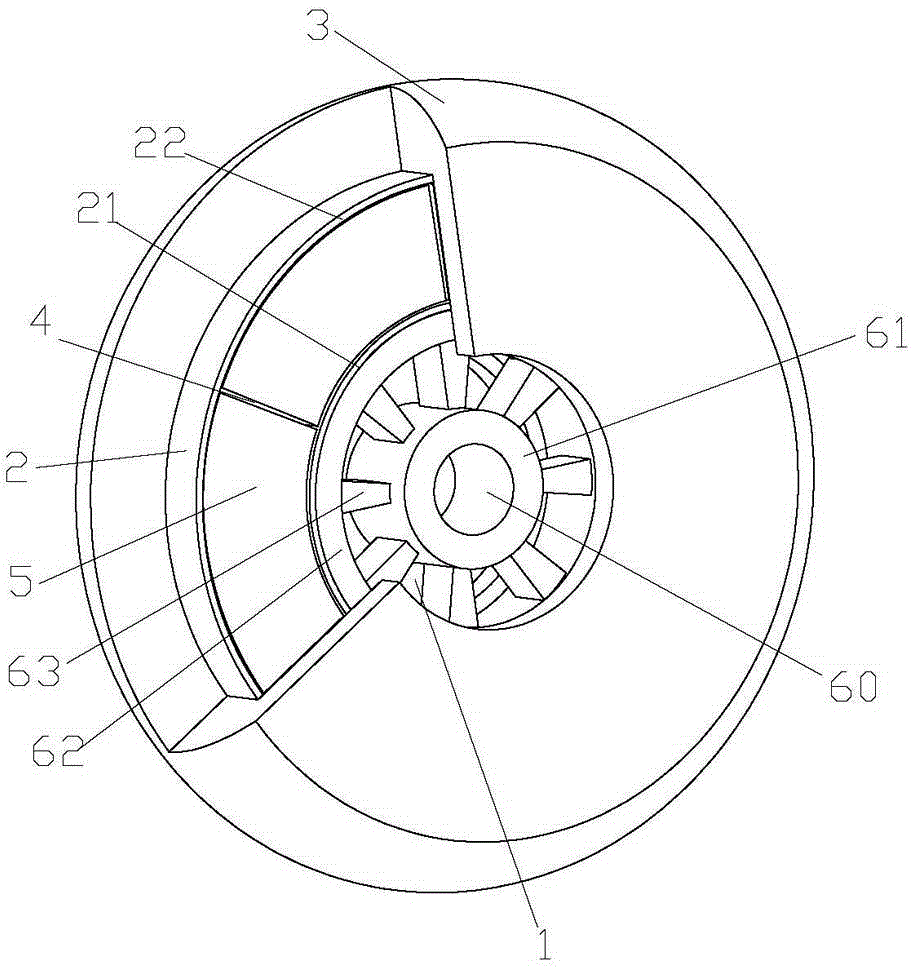

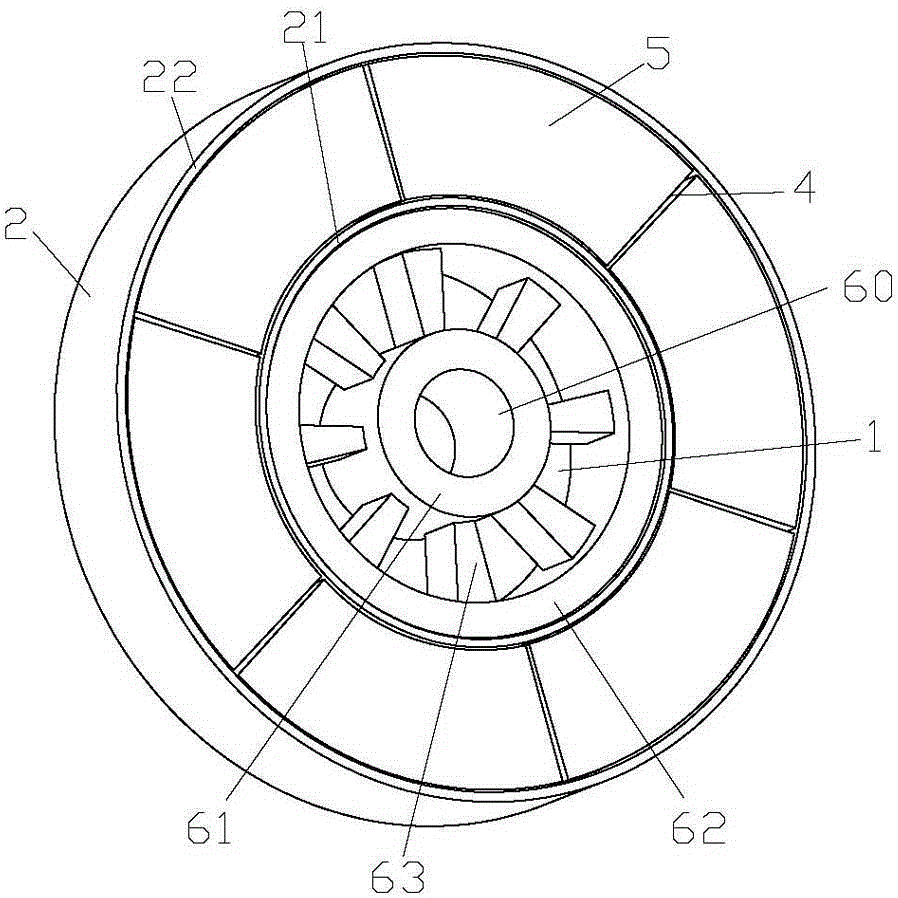

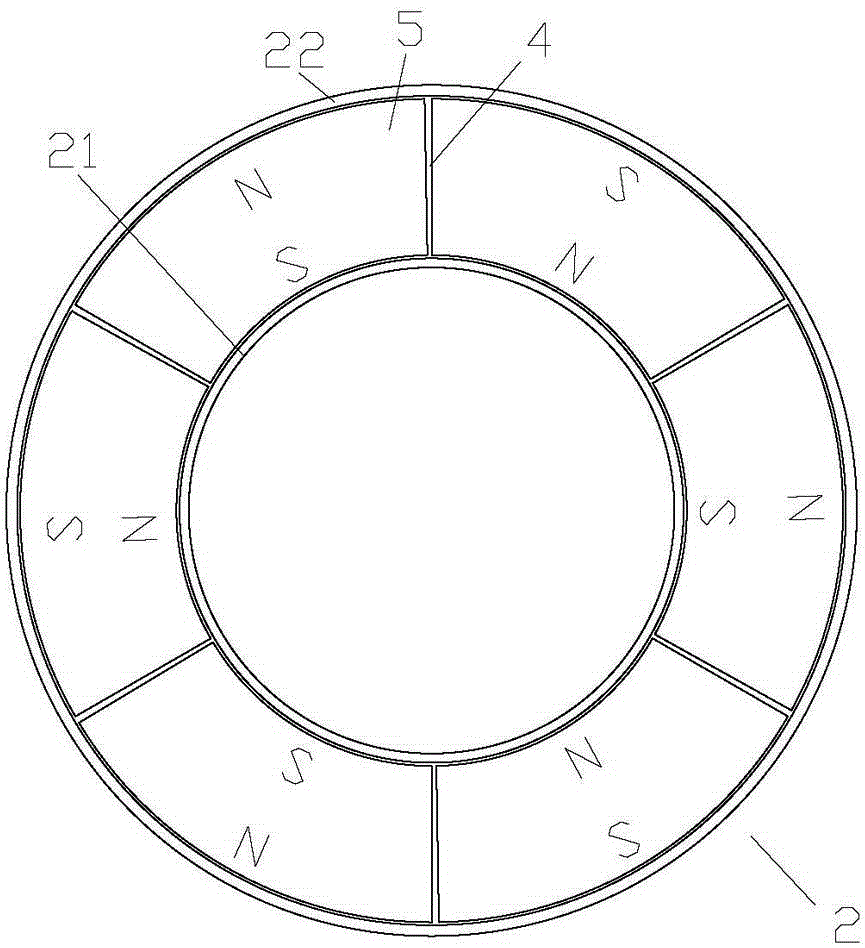

Magnetic massage wheel and massage mechanism

ActiveCN105167976AImprove effective utilizationStrong magnetic health effectRoller massageMagnetotherapy using variable magnetic fieldsPhysical medicine and rehabilitationMassage

The invention relates to the technical field of healthcare equipment, in particular to a magnetic massage wheel and a massage mechanism. The magnetic massage wheel comprises a left wheel body and a right wheel body, and the left wheel body and the right wheel body are structurally identical and in abreast connection. Each of the left wheel body and the right wheel body comprises an inner reinforcement supporting wheel, a magnetic ring peripherally sleeves each of the inner reinforcement supporting wheels, an outer massage direct action wheel peripherally covers an integral structure formed by each inner reinforcement supporting wheel and the corresponding magnetic ring, and a wheel side portion of the outer massage direct action wheel of the left wheel body is connected with a wheel side portion of the outer massage direct action wheel of the right wheel body. Highfield, high structural stability and effectiveness in massage and magnetic healthcare are achieved.

Owner:HEYE HEALTH TECH CO LTD

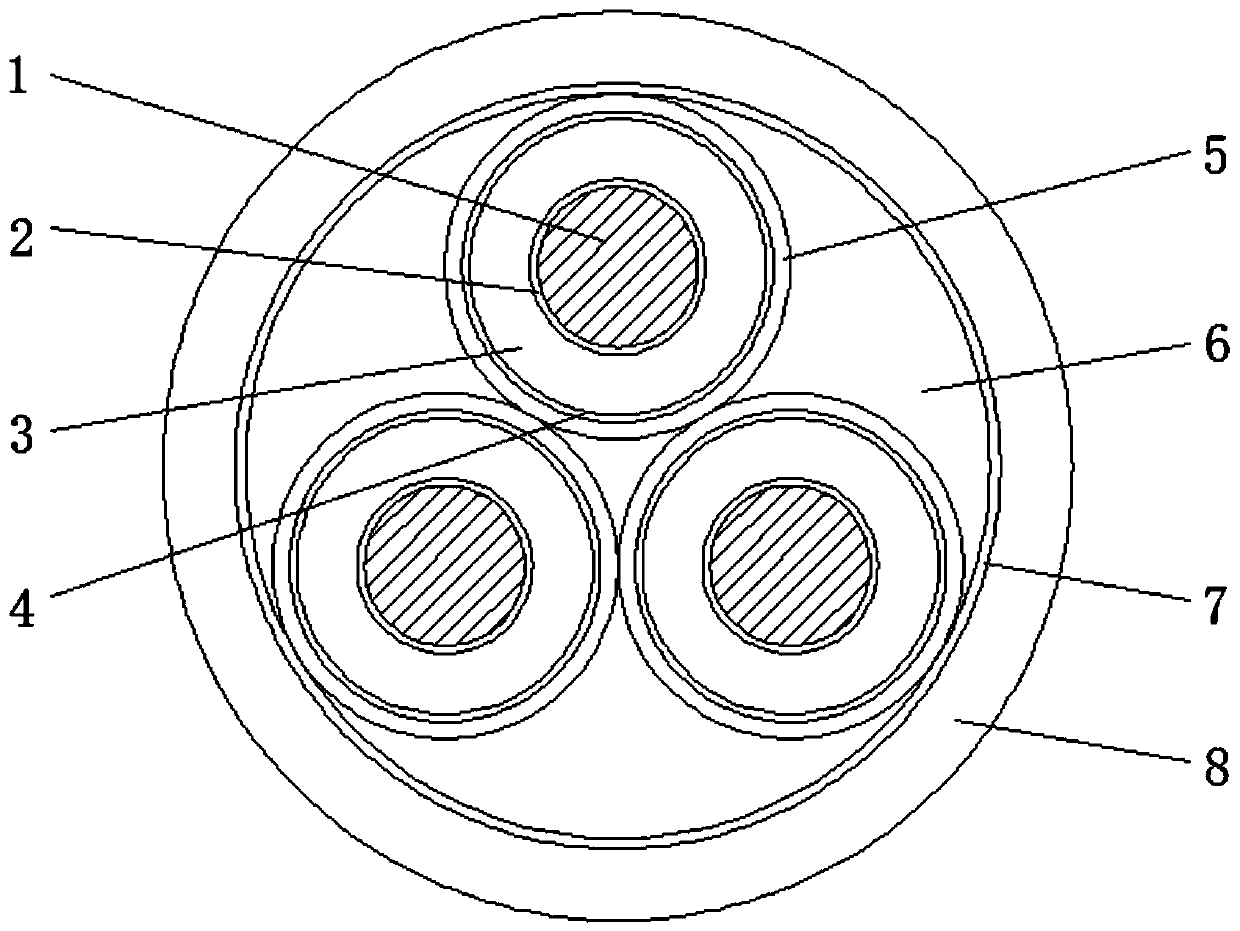

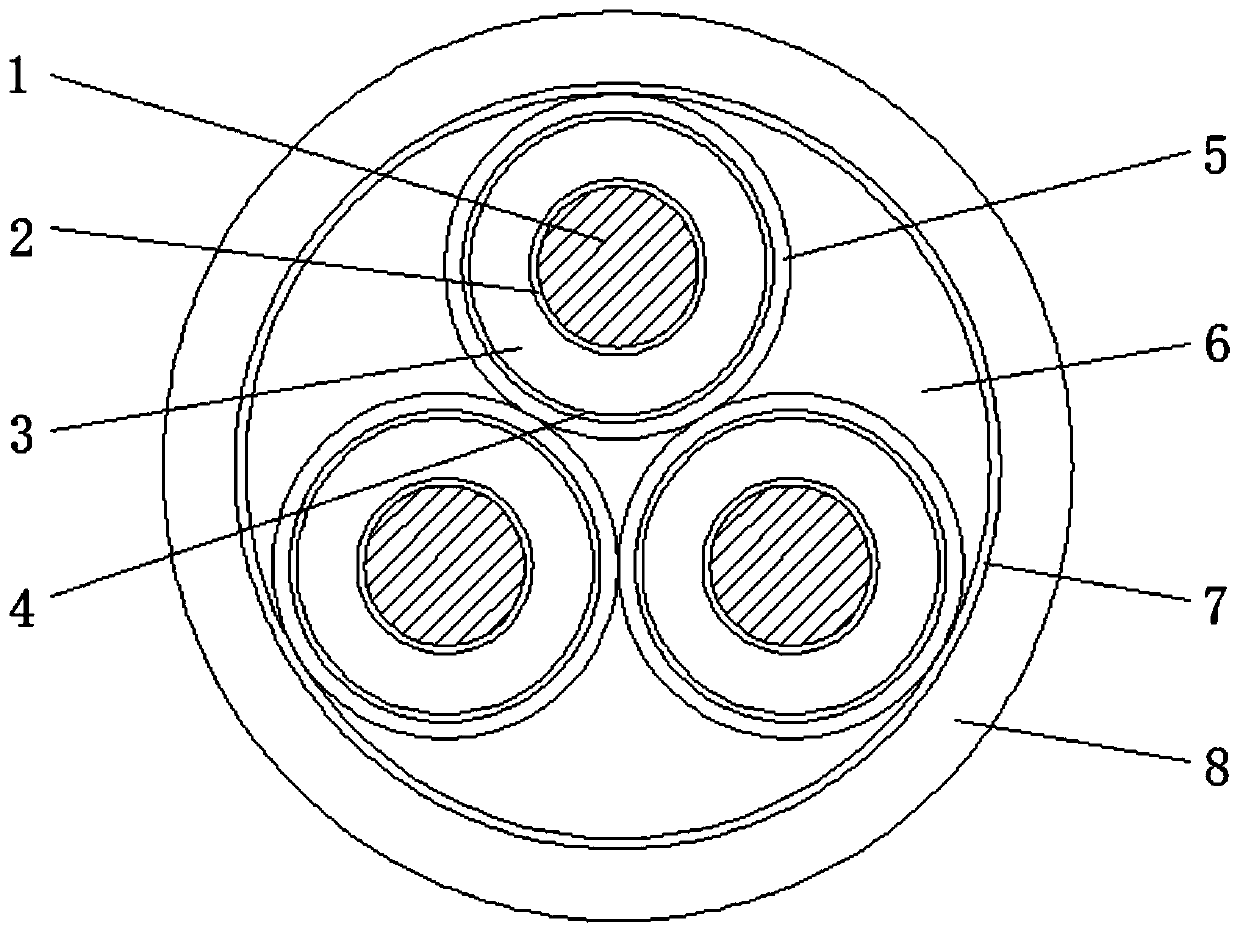

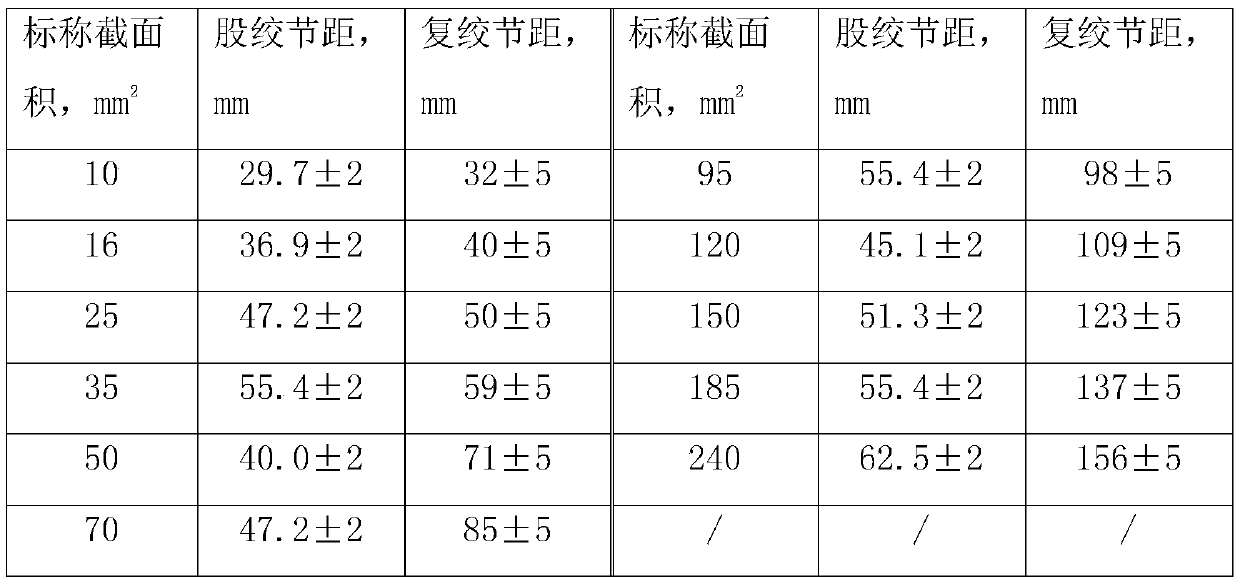

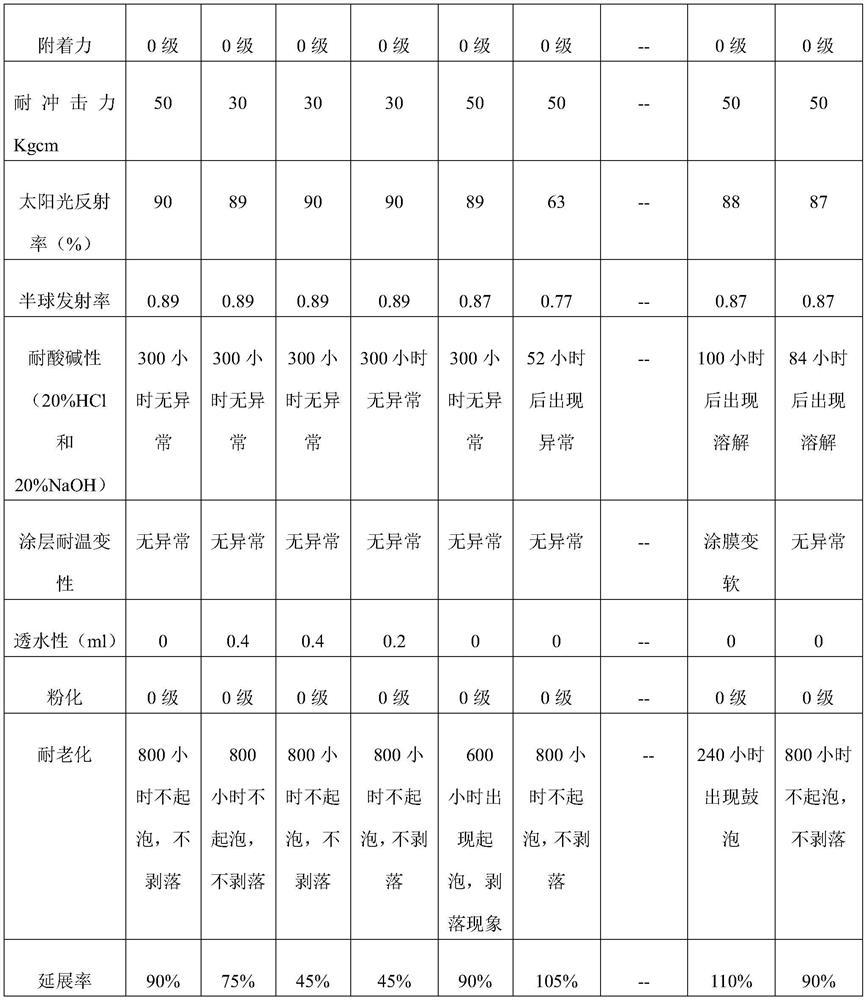

Medium-voltage rubber jacketed flexible cable for offshore wind power generation

InactiveCN110033887ALow costImprove structural strengthApparatus for heat treatmentPower cables with screens/conductive layersElectrical conductorEngineering

The invention discloses a medium-voltage rubber jacketed flexible cable for offshore wind power generation, and belongs to the field of electric wires and cables. The medium-voltage rubber jacketed flexible cable comprises a cable core, a water-blocking wrapping tape and an outer sheath; the water-blocking wrapping tape wraps the outer side of the cable core; the outer sheath wraps the outer sideof the water-blocking wrapping tape in an extrusion mode; the cable core is formed by twisting three power wire cores and a water-blocking filling strip; the center in each power wire core is filled with a conductor; the outer side of each conductor is wrapped with a conductor shielding layer; an insulating sleeve wraps the outer side wall of each conductor shielding layer in an extrusion mode; aninsulating shielding layer wraps the outer side of each insulating sleeve; and a metal shielding layer wraps the outer side of each insulating shielding layer. The scandium-aluminum alloy conductorsare adopted, so that the defect that pure copper is used as electric wire and cable conductors is effectively overcome, the cost of the cable is reduced, the structural strength, the elongation, the tear resistance and the like of the cable core are effectively improved, and the defect that a traditional cable is poor in bending performance is overcome; and the cable is effectively suitable for medium-voltage cables and is convenient to popularize for a long time.

Owner:ANHUI LINGYU CABLE TECH

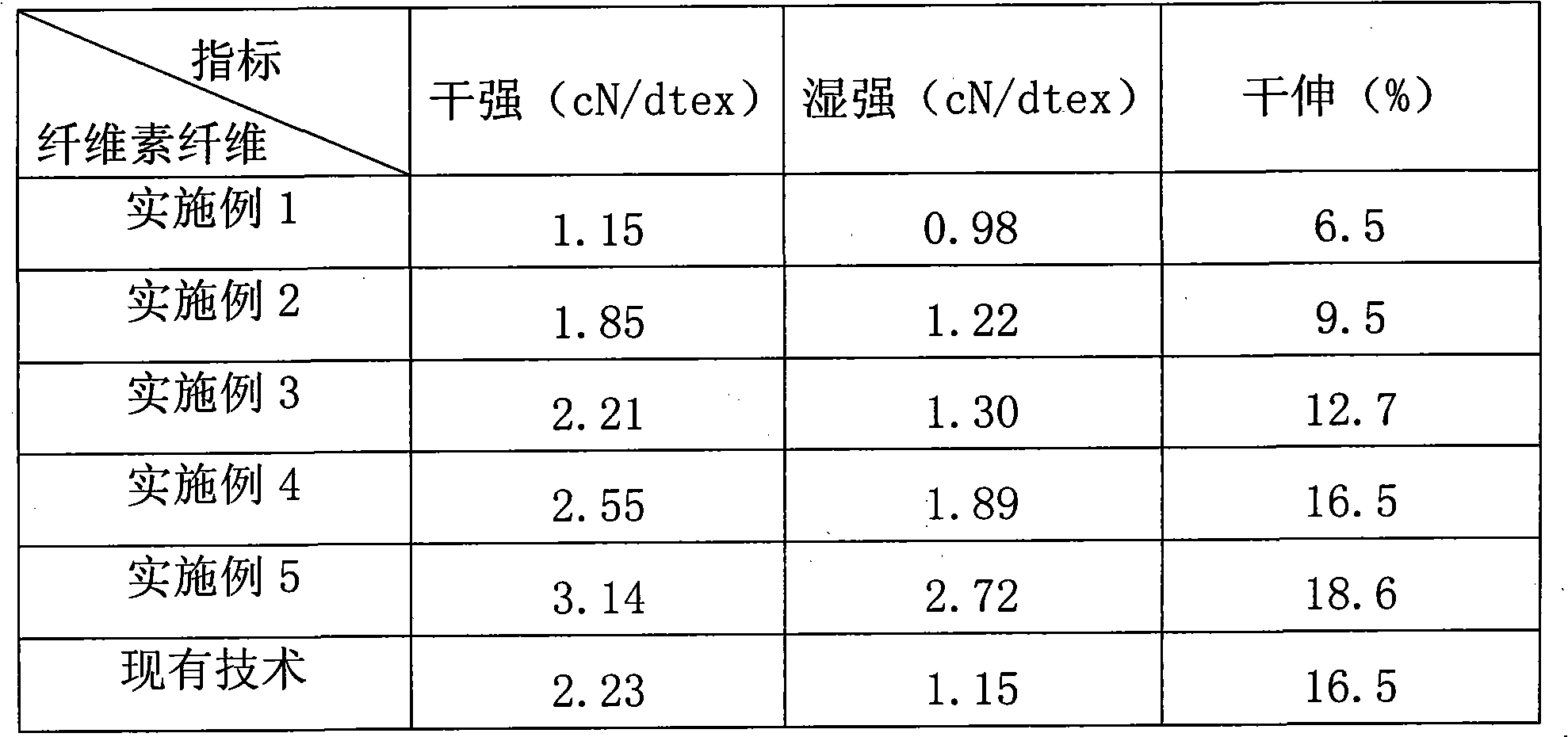

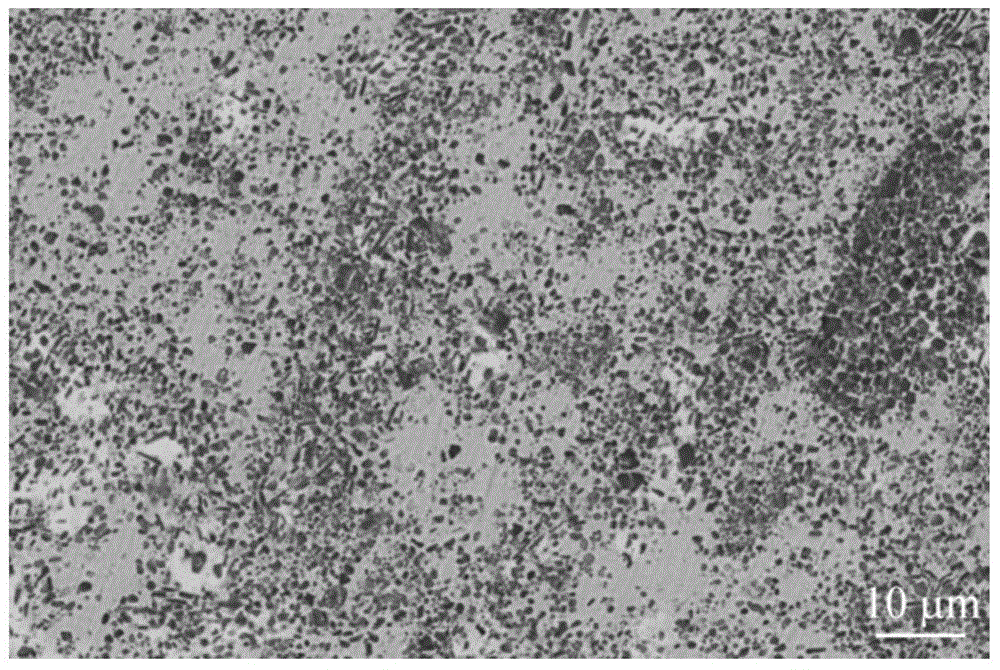

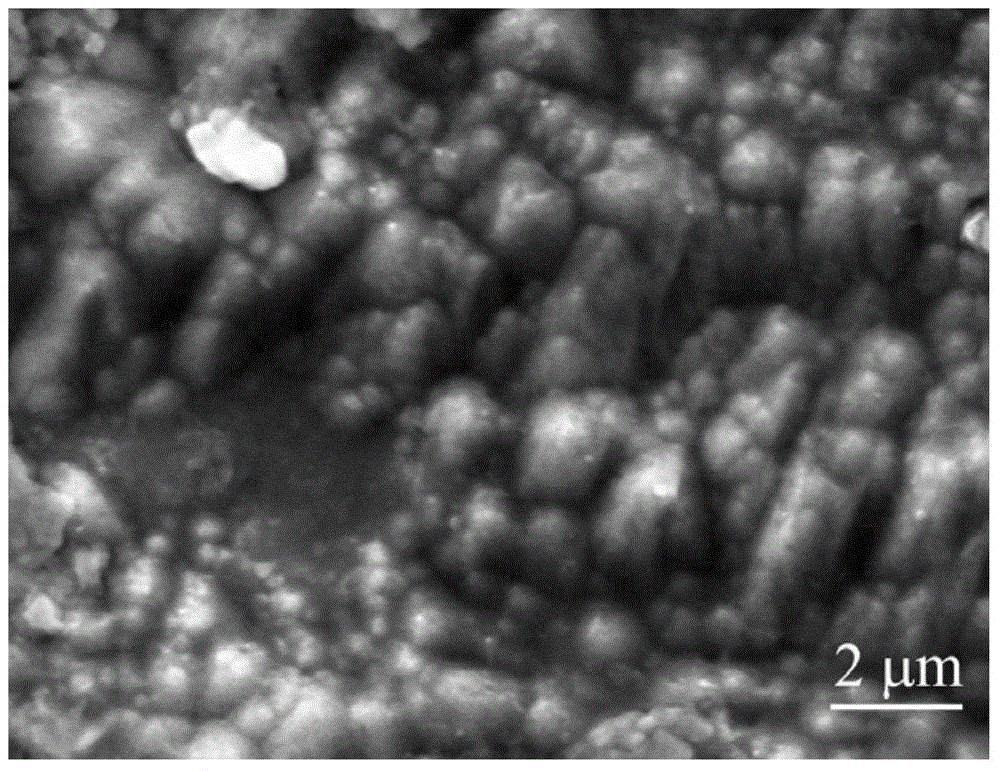

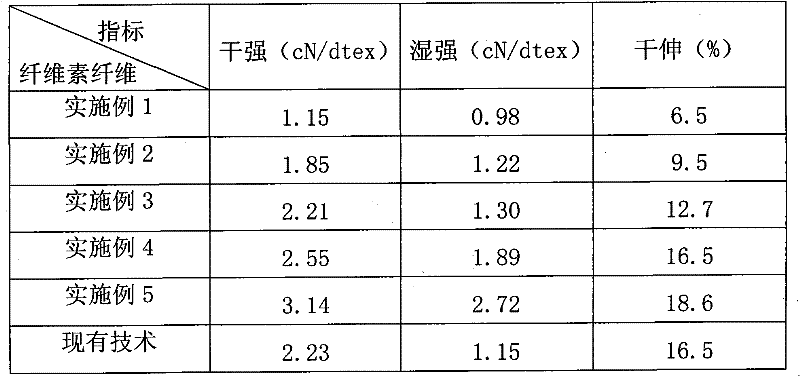

Calamine cellulose fiber and preparation method thereof

ActiveCN101985781AImprove solubilityAvoid it happening againArtificial filaments from cellulose solutionsWet spinning methodsYarnFunctional indices

The invention relates to a calamine cellulose fiber, which is characterized in that the formed calamine cellulose fiber is obtained through the following processes: preparing calamine slurry, preparing a spinning solution, preparing a denatured spinning solution and spinning; the weight percentage of the calamine in the finished product calamine cellulose fiber is 5% to 25%; the yarn is dissolved by adopting ionic liquid so as to increase the dissolubility of the yarn and enhance the production efficiency; a large amount of hydrogen sulfide and carbon disulfide can be avoided from generating in the yellowing process when the traditional viscose process is adopted; the environment pollution is reduced; the damage on the health of operation personnel is lightened; the ionic liquid is adopted to serve as a coagulating bath solution so as to guarantee that the effective components in the calamine are not damaged; the functional index of the finished product fiber is enhanced; the wet-dry strength and the dry extension are obviously enhanced; and the bleaching process in the course of preparing the conventional spinning solution fiber in the postprocessing process is omitted so as to avoid the damage of bleaching substances on the calamine and antibiosis active substances in the calamine.

Owner:潍坊欣龙生物材料有限公司

Welding wire made of Cr28 Ni48 W5 nickel base alloy

ActiveCN103949800AImprove antioxidant capacityImprove liquidityWelding/cutting media/materialsSoldering mediaSlagForging

The invention relates to a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. A method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

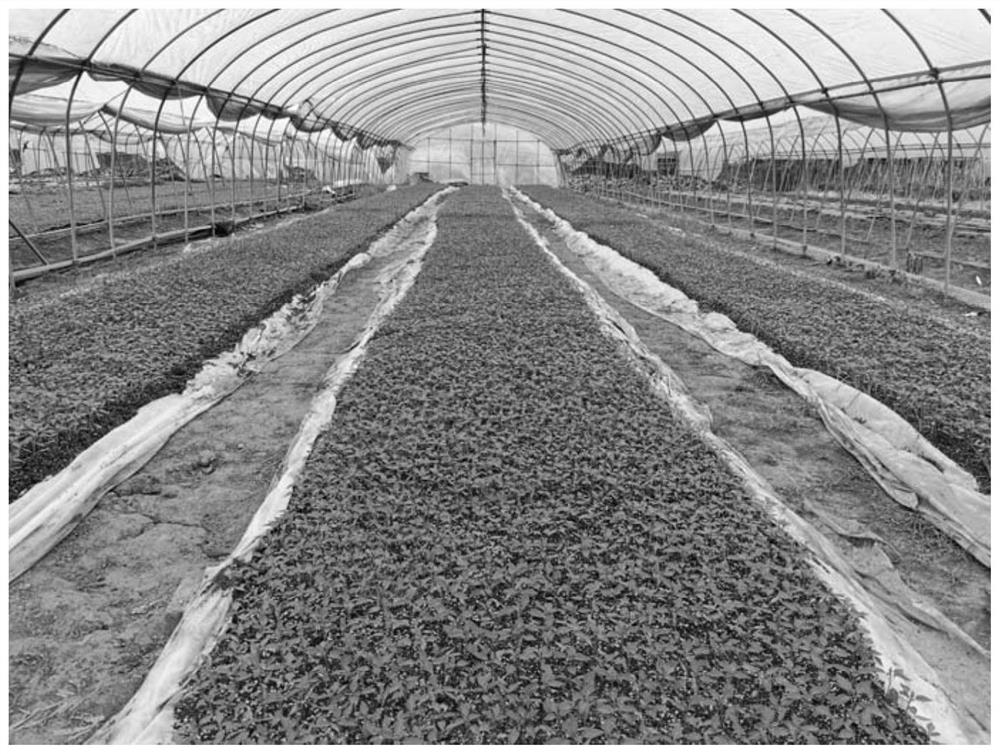

Efficient pepper matrix seedling raising method

PendingCN112690180APrevention and treatment of seedling diseasesImprove germination ratePlanting bedsAlkali orthophosphate fertiliserFermentationBiological organism

The invention relates to the technical field of planting, and particularly discloses an efficient pepper matrix seedling raising method which comprises the following steps of (1) seedbed preparation; (2) seedling matrix treatment; (3) germination accelerating; (4) sowing; (5) seedling management; and (6) temporary planting and management. According to the method, a matrix is laid on a seedbed padded with a thin film for seedling raising, and compared with 60-hole tray seedling raising, the seedling yield can be increased by 35% under the same seedling shed area. In the seedling raising process, a 150-fold solution of biological nano-selenium microbial fertilizer 'Zhenxi', a 300-fold solution of an intense fermentation fertility increasing solution 'EM stock solution', a 3000-fold solution of a synergist 'Beibeijia', a 600-fold solution of amino acid-containing water-soluble fertilizer 'Yuhuanling No.2' and the like are comprehensively used, and compared with a traditional method, the germination rate of pepper seeds can be increased, pepper seedling growth is facilitated, and the pepper seedling quality is improved.

Owner:桂林市农业科学研究中心

Ultrafine ceramic particle Cu based composite material taking Ti2SnC as precursor and preparation method of composite material

The invention discloses an ultrafine ceramic particle Cu based composite material taking Ti2SnC as a precursor and a preparation method of the composite material. Micron-sized Ti2SnC with the volume content of 3-50% and micron-sized Cu serve as starting materials, ultrafine TiC0.5 particles are generated and uniformly dispersed in a Cu (Sn) matrix after reaction, and Cu crystalline grains are refined into sub-micron grade. The preparation method of the composite material includes the steps: uniformly mixing Ti2SnC powder and Cu powder on a ball mill and then forming the powder under the pressure of 120-250MPa; placing the powder into a high-temperature furnace; performing argon protection; increasing the temperature of the furnace to reach 1100-1250 DEG C; keeping the temperature for 30-60min; cooling the powder to obtain the ultrafine ceramic particle Cu based composite material. The preparation method has the remarkable advantages of simple process, convenience in operation and the like. The ultrafine ceramic particle Cu based composite material has the advantages of high strength and ductility, abrasion resistance and erosion resistance, and can be widely applied to the field of military equipment, high-speed railways, aerospace and the like such as high-strength box shell materials.

Owner:BEIJING JIAOTONG UNIV

High-ductility electrolytic copper foil surface reddening method

The invention discloses a high-ductility electrolytic copper foil surface reddening method which has the following technical points: cellulose ether is added into a coarsening electrolyte for coarsened layer treatment, and the pH values of a graying electrolyte for graying treatment and a passivating electrolyte for passivating treatment are respectively 10-15. The copper foil coarsened surface produced by the invention has fine and uniform crystal grains, thereby reducing the skin effect of the copper foil when the circuit board is made into a circuit, preventing rear side corrosion caused by excessive dissimilar metal coatings in the preparation process of the copper clad plate, maintaining the characteristic of high ductility of the high-ductility electrolytic copper foil, and being beneficial to enhancing the chemical affinity between the copper foil and substrate and improving the peel strength and oxidation resistance. The invention belongs to the technical field of electrolytic copper foils.

Owner:梅州市梅县区金象铜箔有限公司

Preparation method of calamine cellulose fiber

ActiveCN101985781BImprove solubilityAvoid it happening againArtificial filaments from cellulose solutionsWet spinning methodsFunctional indicesYarn

Owner:潍坊欣龙生物材料有限公司

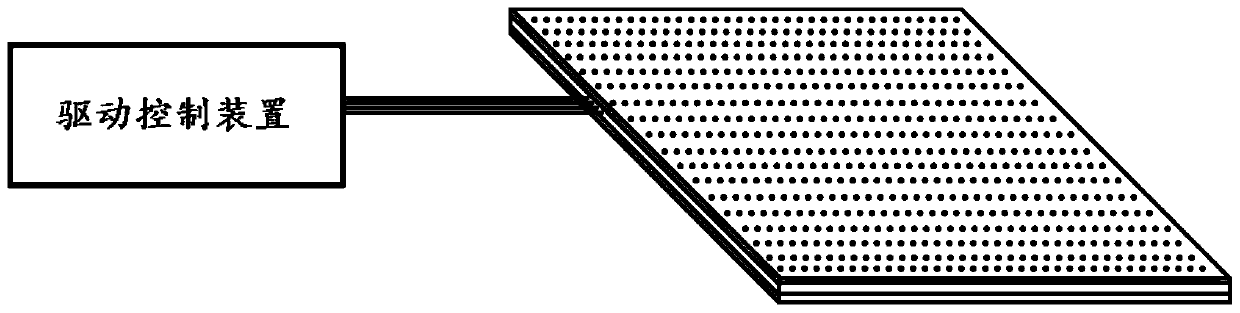

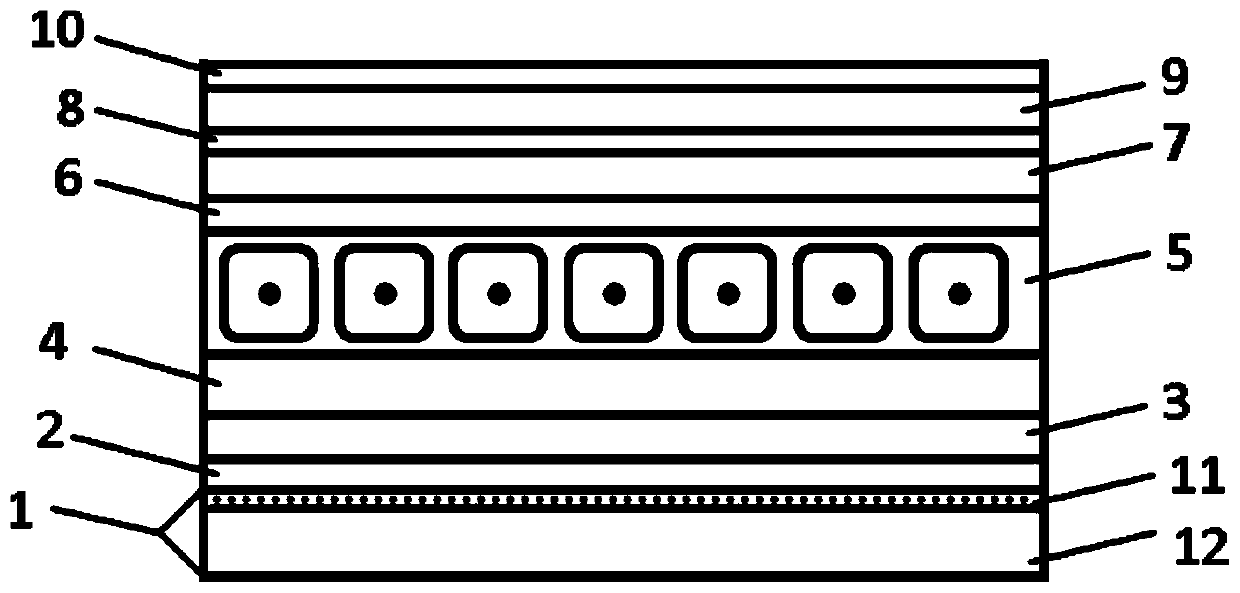

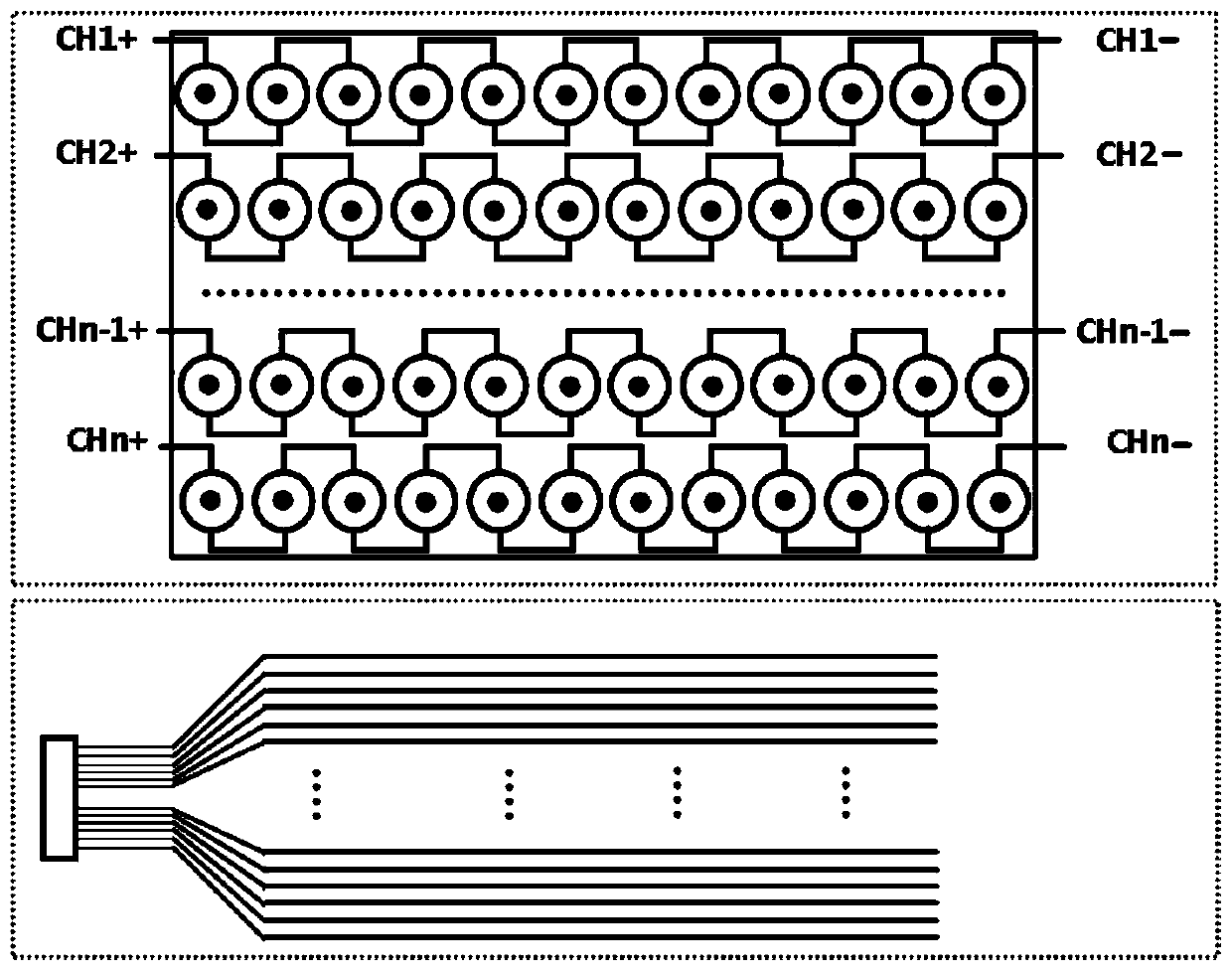

LED flexible display screen

InactiveCN111583806AColorfulLarge viewing angleStatic indicating devicesIdentification meansLed arrayEngineering

The invention provides an ultrathin LED flexible display screen which comprises a display module and a drive control device, and the display module is connected with the drive control device through adata line. The display module sequentially comprises a supporting layer, a first energy absorption layer, a driving connection layer, a second energy absorption layer, an LED array layer, a thin filmpackaging layer, a third energy absorption layer, a light polarization layer, a fourth energy absorption layer and a panel protection layer from bottom to top. According to the flexible display screen, the energy absorption layers are arranged, so that the high-elasticity and high-extension energy absorption layers are arranged among all the layers, when the shape of the flexible display screen is changed according to requirements of a user, stress gathered on all the functional layers of the flexible display screen can be effectively released by means of the energy absorption layers, and therefore normal work of the flexible display screen is guaranteed.

Owner:深圳市美亚迪光电有限公司

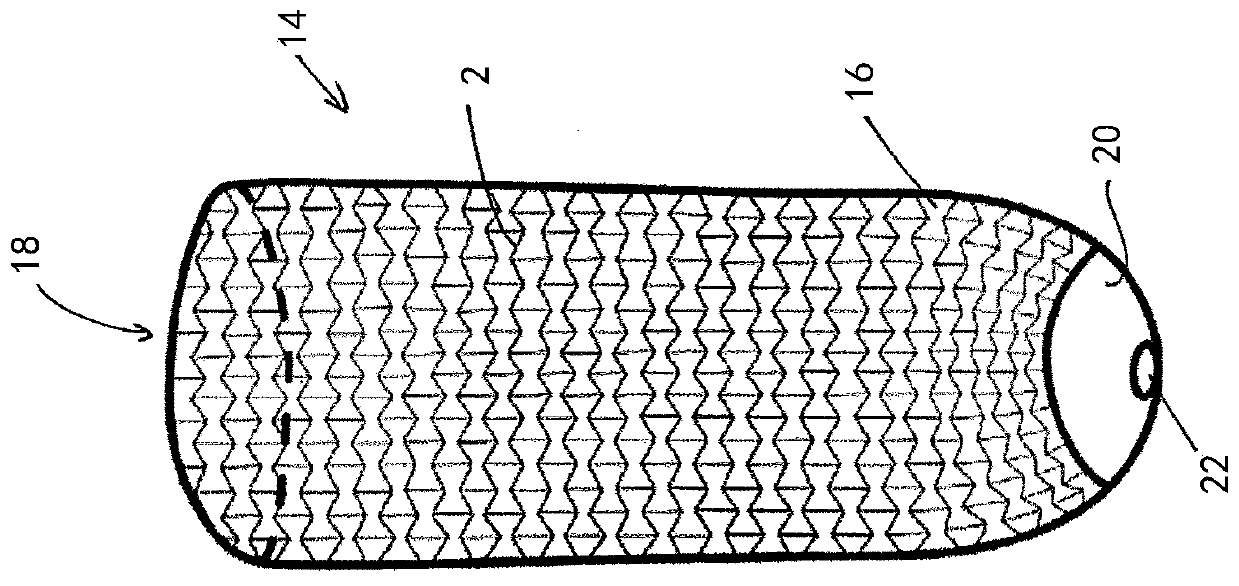

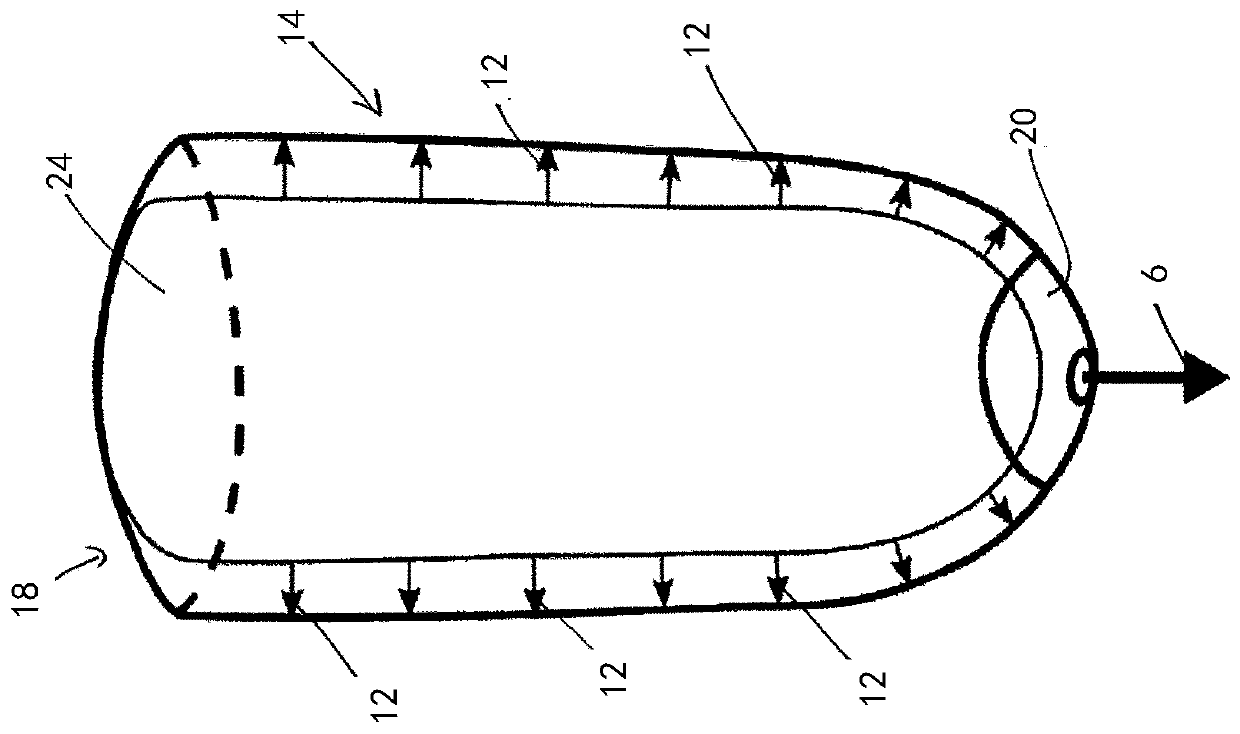

Liner for prosthesis

ActiveCN110461277AImprove extensionPromote blood circulationMonocomponent polypropylene artificial filamentProsthesisAuxeticsLimb amputation

The invention relates to a liner (14) for a prosthesis, said liner being made of a liner material (16) and comprising a proximal opening (18) for accommodating an amputation stump (24), a distal end (20), a longitudinal direction that extends from the proximal opening to the distal end, and an auxetic material.

Owner:OTTOBOCK SE & CO KGAA

Aluminium alloy heat exchange tube

The weight proportion of the raw material in the alloy is: Al 98.17~98.75, Si 0.2~0.38, Mg 0.6~0.9, Fe 0.2~0.25. Cu 0.25~0.3, in which, Cu in it strengthens the hardness and extension power of the Al alloy tubes, Mg increases the plasticity and acid-resistant performance cracks do not appear on the turning arc of the tube by this invention.

Owner:陈继忠

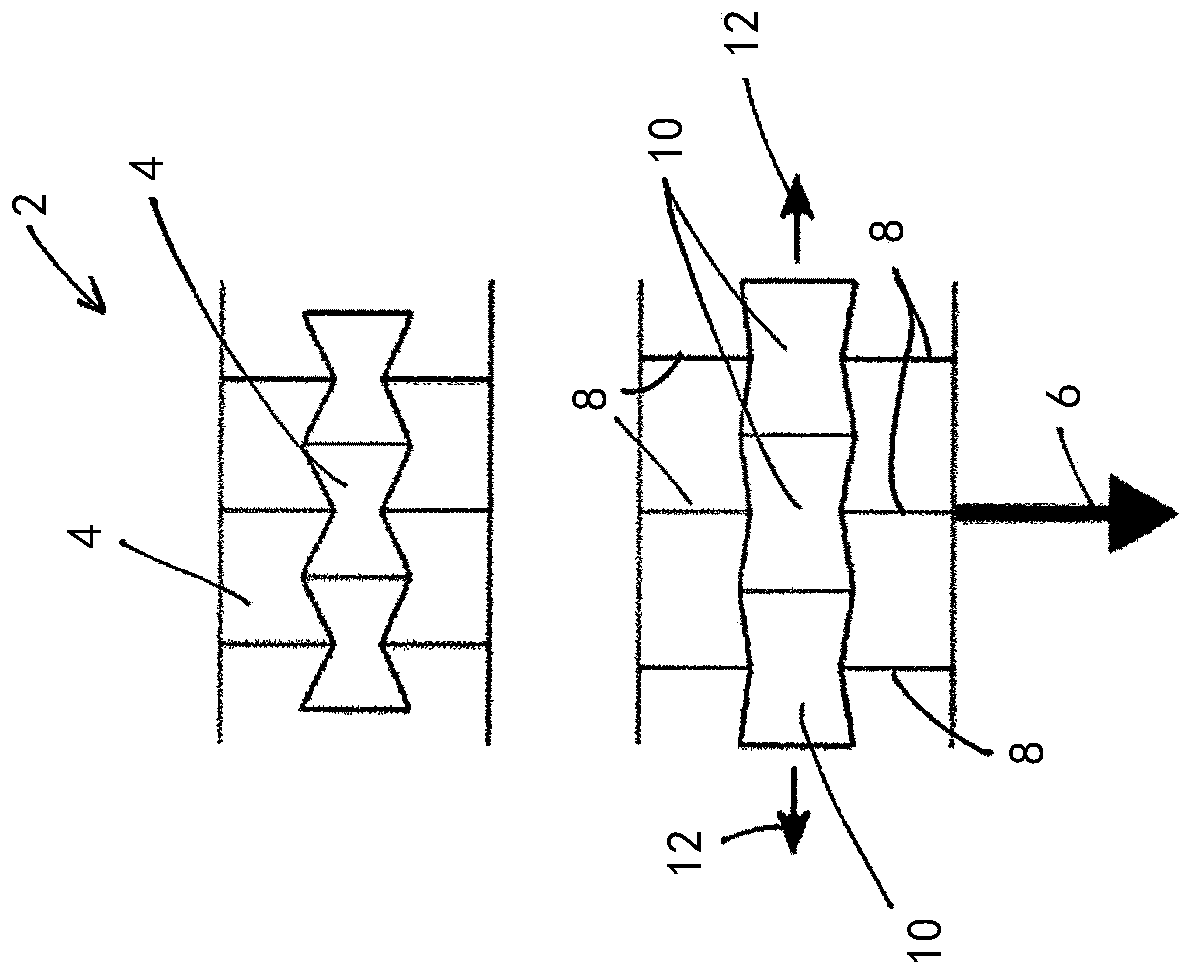

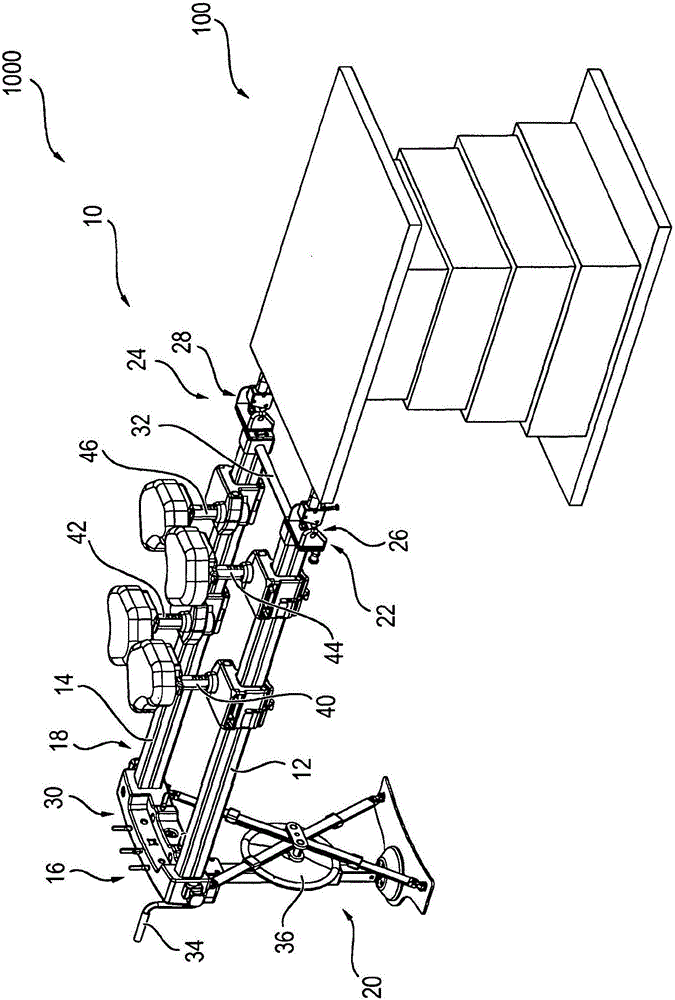

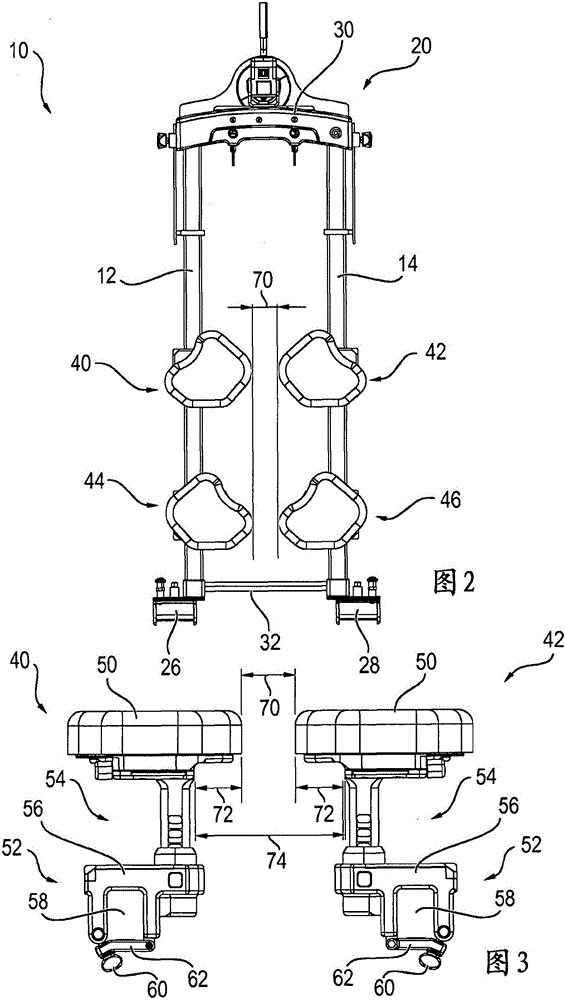

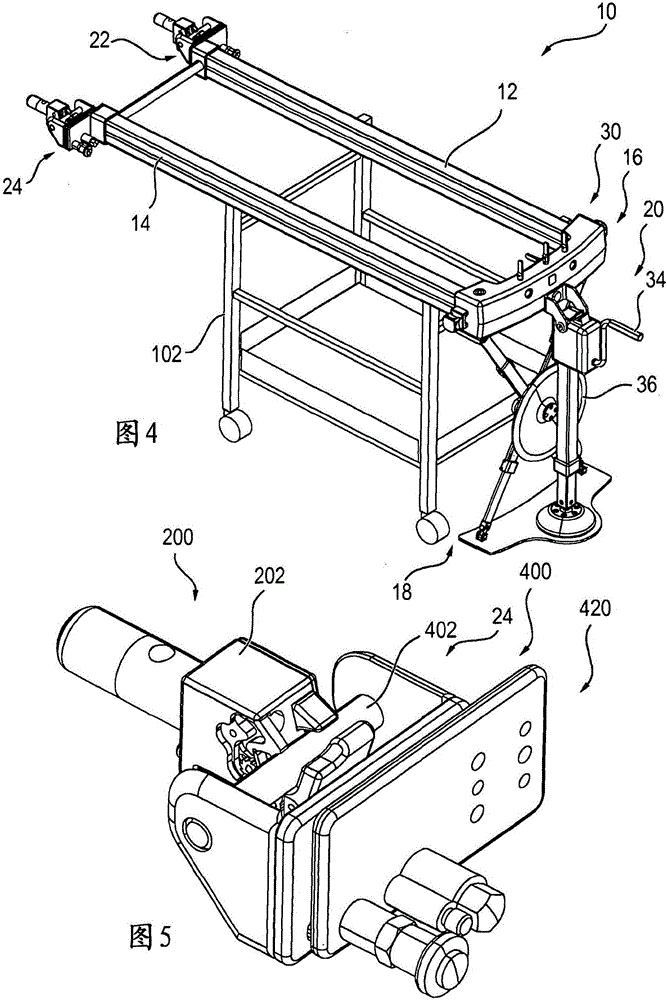

Fastening unit for fastening device for supporting patient to be X-rayed to operating table

InactiveCN105792788AImprove extensionImprove approachOperating tablesPatient positioning for diagnosticsCouplingLocking mechanism

The invention relates to an operating-table-side fastening unit (200) and to a device-side fastening unit (400) for fastening a device (10) for supporting a patient to be x-rayed to an operating table (100). The operating-table-side fastening unit (200) comprises a receptacle (204) for receiving a coupling element (402) of the device-side fastening unit (400). Furthermore, the operating-table-side fastening unit (200) comprises a bolt (206), which is preloaded in a locked position, in which the bolt prevents the coupling element (402) from being removed from the receptacle (204). By means of a locking mechanism (240), the bolt (206) is held in an unlocked position after actuation by means of an actuating element (214) until either the coupling element (402) has been removed from the receptacle (204) or the actuating element (214) has been actuated again. The device-side fastening unit (400) comprises a mounting unit (406) and an intermediate piece (404), which are rotatably fastened to each other such that a height adjustment is possible by orienting the intermediate piece (404) in relation to the mounting unit (406).

Owner:MAQUET GMBH

Method of preparing polypeptide-amino acid metal-ion chelated liquid fertilizer by taking enzymolysis residue oxidation product as chelating agent

The invention discloses a method of preparing polypeptide-amino acid metal-ion chelated liquid fertilizer by taking an enzymolysis residue oxidation product as a chelating agent. The method is characterized by comprising the following steps: adding distilled water into enzymolysis residues to prepare a suspension, adding a KMnO4 solution, carrying out an oxidation reaction by heating, and carryingout centrifugation on the mixture obtained after the reaction to obtain an oxidation product; adding sulfuric acid to keratin, carrying out a hydrolysis reaction in a reaction kettle, adding a strongbase, carrying out a neutralization reaction, carrying out stirring and sieving, adding a chelating agent, the liquid phase of the oxidation product and trace elements into the filtrate, and carryingout stirring to prepare a polypeptide-amino acid stock solution; and filtering the obtained polypeptide-amino acid stock solution, adding the solid phase of the obtained oxidation product, carrying out mixing, and carrying out a cheating reaction with inorganic elements which are four metal ions comprising iron ions, copper ions, zinc ions and manganese ions to prepare the polypeptide-amino acidmetal-ion chelated liquid fertilizer.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

Power lithium battery flexible packaging film

ActiveCN112652844AHigh barrierAvoid punctureLi-accumulatorsCell component detailsPhysical chemistryPolypropylene

The invention discloses a power lithium battery flexible packaging film, which comprises the following raw materials in parts by weight: 20-26 parts of a micro-cross-linked polypropylene inner layer, 15-18 parts of a modified aluminum foil middle layer, 10-15 parts of a modified PET outer layer, 3-6 parts of an adhesive and 3-6 parts of a primer, and is prepared from the cross-linked polypropylene inner layer, the modified aluminum foil middle layer and the modified PET outer layer through a hot-pressing laminating process. According to the invention, modification is carried out based on the multi-layer aluminum-plastic composite film, macroscopically, effective compounding of the modified PET outer layer, the modified aluminum foil middle layer and the micro-crosslinked polypropylene inner layer is realized, and in microstructure, doping compounding of organic and inorganic elements is realized, so that the performance requirements of corrosion resistance and high ductility of the power lithium battery flexible package film are met, and the barrier capacity of the power lithium battery flexible package film to oxygen and moisture is also improved.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

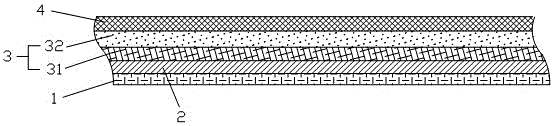

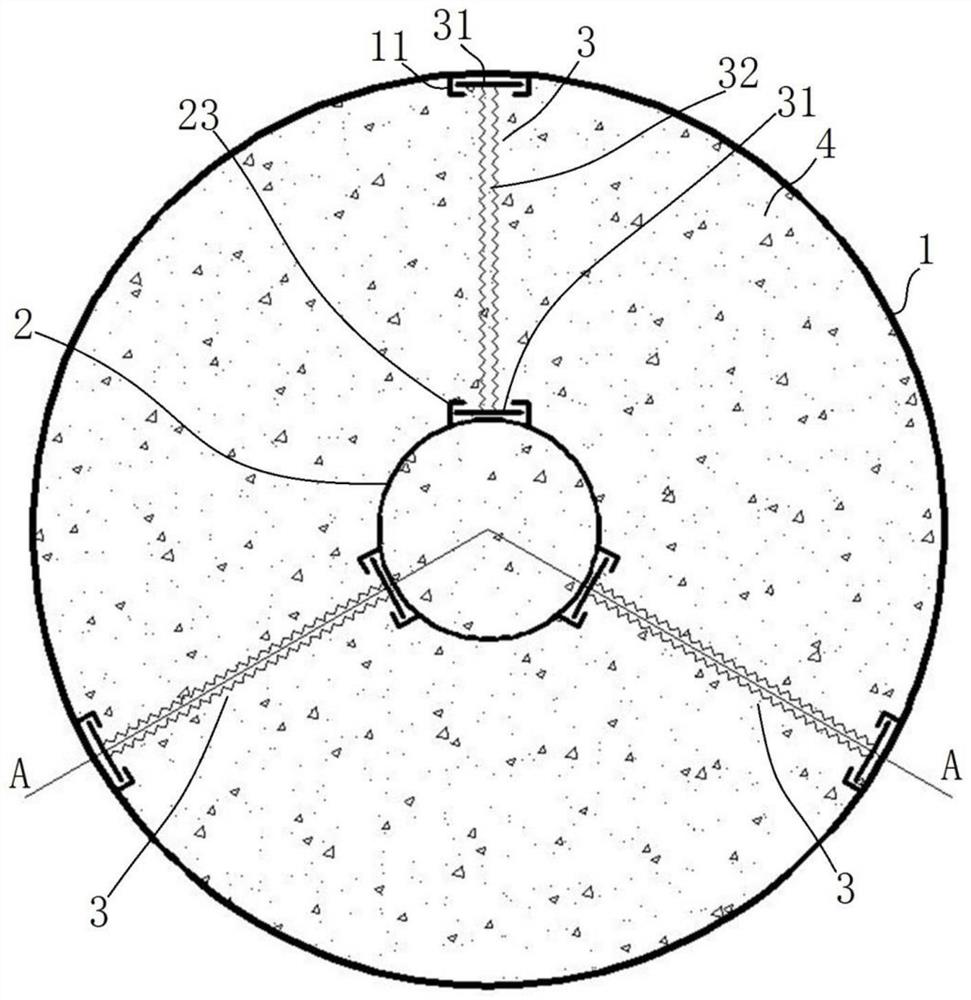

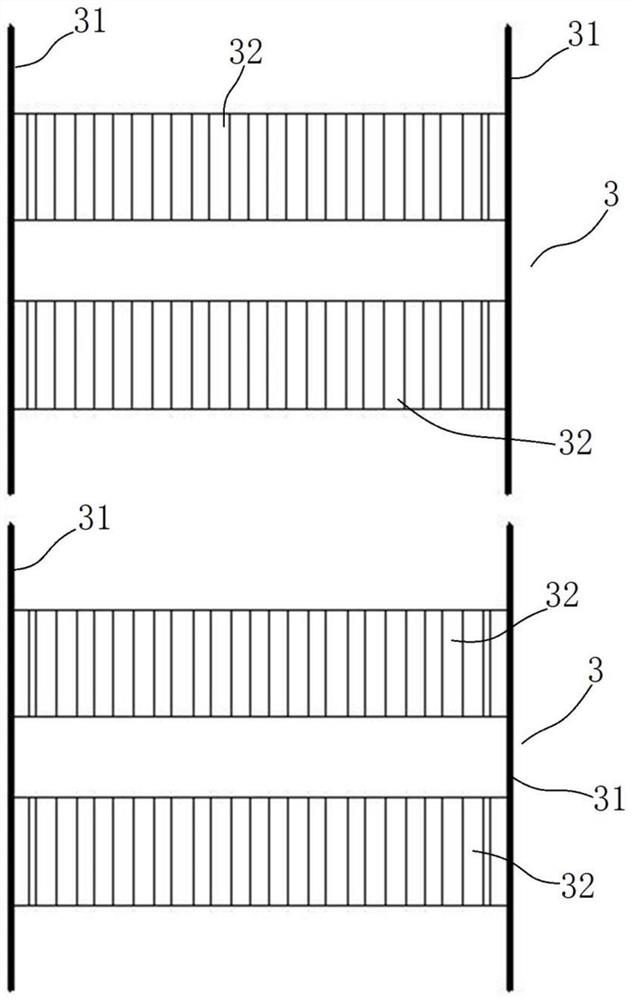

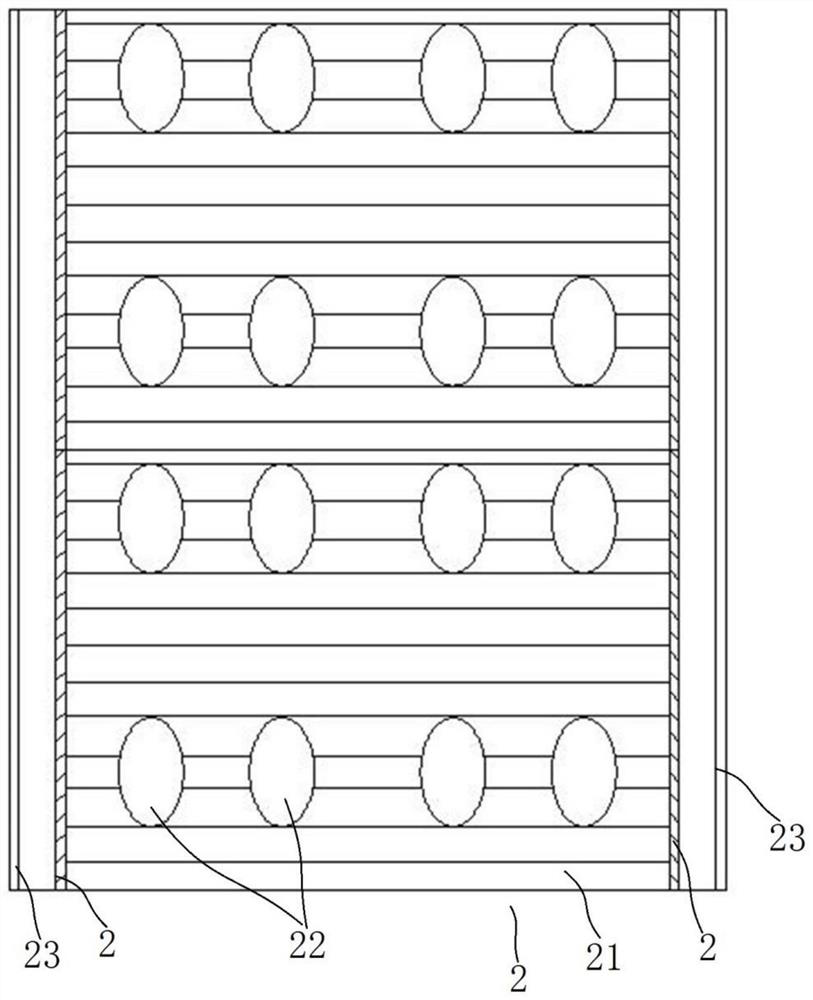

Reinforced waterproof roll

InactiveCN106515135AImprove tensile propertiesImprove extensionRoof covering using flexible materialsSynthetic resin layered productsGlass fiberEthylene-propylene-diene-monomer

The invention discloses a reinforced waterproof roll, and belongs to the field of building waterproofing. The reinforced waterproof roll comprises an isolation layer, a copper and aluminum-based waterproof layer, a reinforcement layer and an EPDM (Ethylene-Propylene-Diene Monomer) rubber layer which are sequentially overlaid. According to the reinforced waterproof roll disclosed by the invention, through raised latticed convex lines, the tensile resistance, the stretching force and the tear resistance of the reinforced waterproof roll are reinforced; through the arrangement of a fiberglass layer, the strength of the reinforced waterproof roll is further increased, and the service life of the reinforced waterproof roll is prolonged; the reinforced waterproof roll has the advantages of compact structure, high strength, stronger tensile resistance and long service life.

Owner:十堰凯林汽车运输有限公司

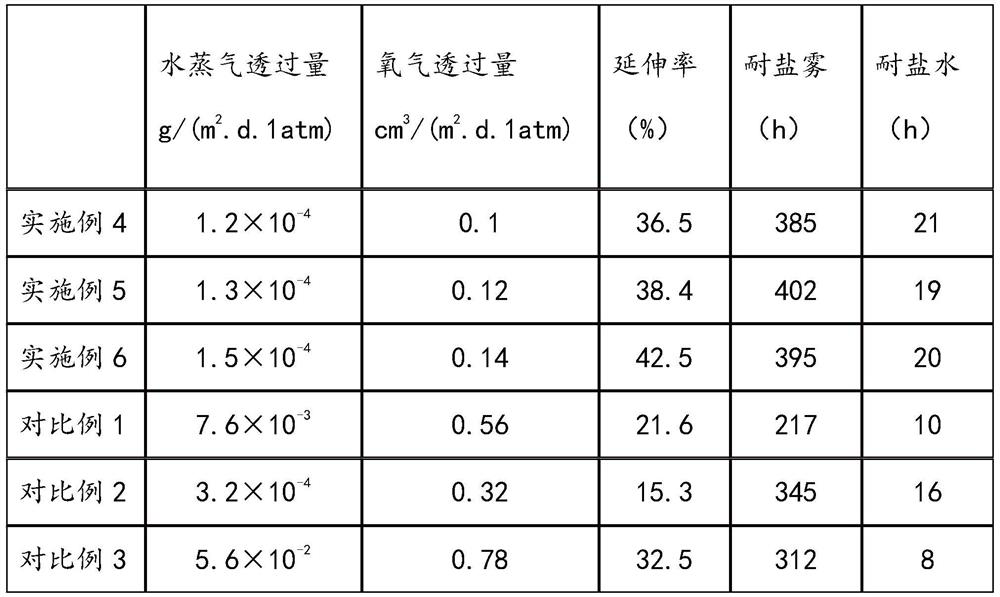

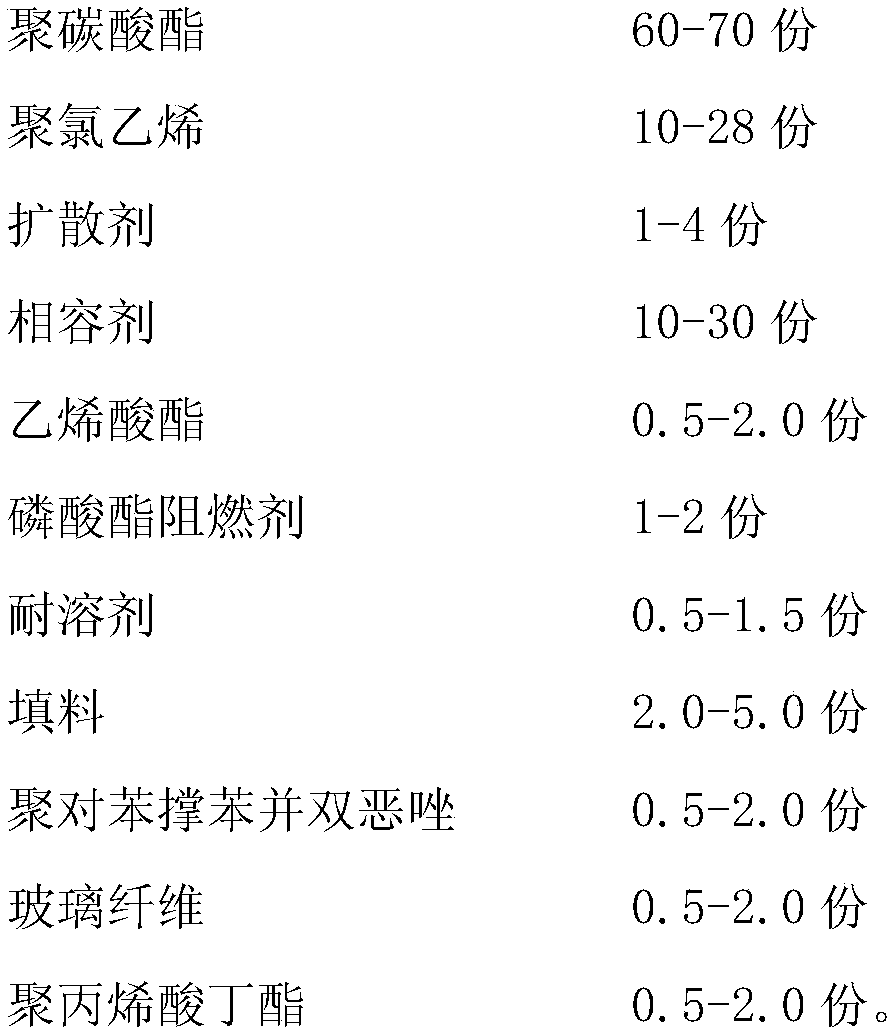

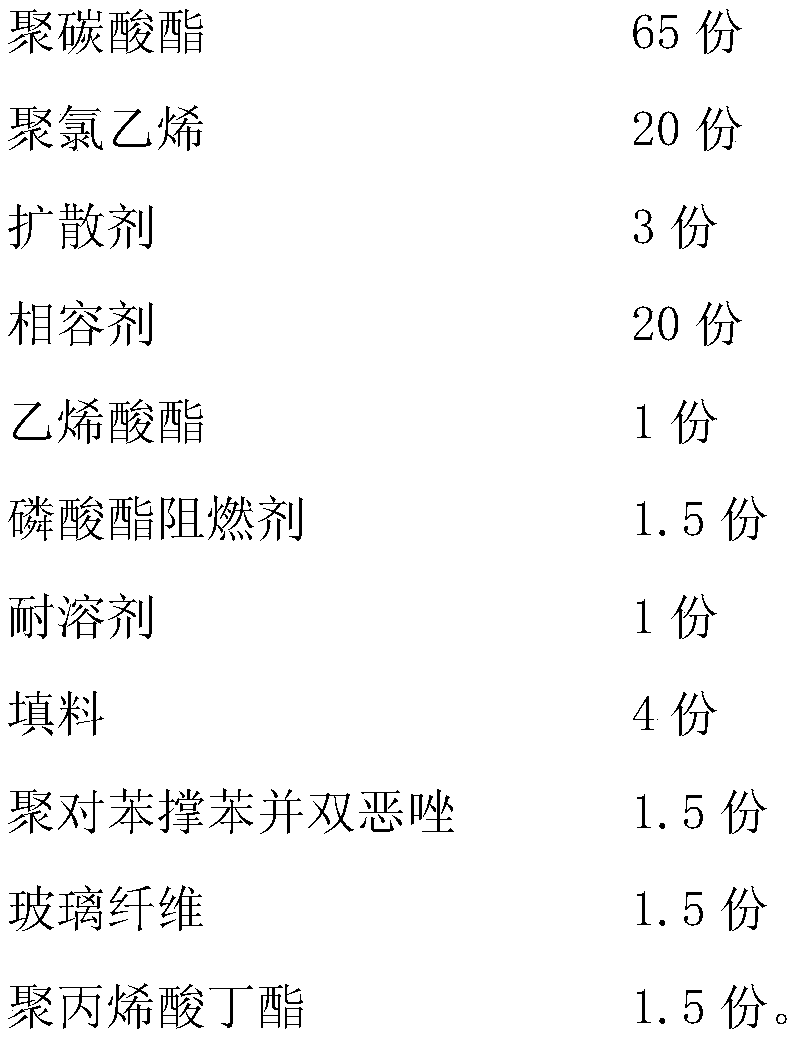

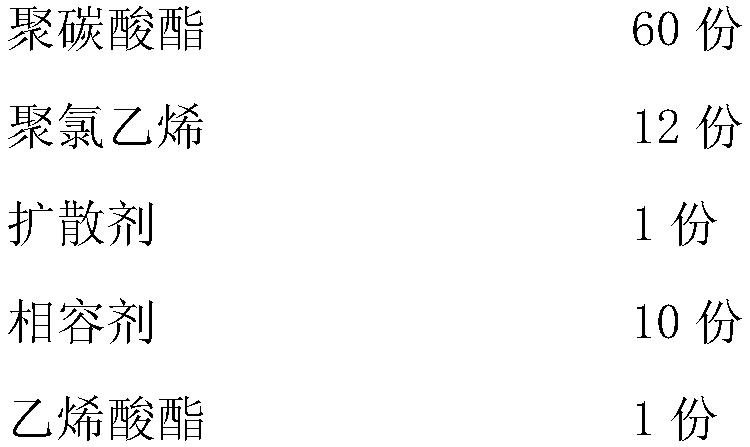

Polycarbonate composite material

The invention relates to a polycarbonate composite material, which belongs to the field of an organic chemical polymer. The polycarbonate composite material comprises the following main raw materials(by in parts by mass): 60-70 parts of polycarbonate, 10-28 parts of polyvinyl chloride, 1-4 parts of a diffusing agent, 0-30 parts of a compatibilizer, 0.5-2.0 of vinyl acid ester, 1-2 parts of a phosphate flame retardant, 1-2 parts of the phosphate flame retardant, 2.0-5.0 parts of a filler, 0.5-2.0 parts of poly(p-phenylene benzobisoxazole), 0.5-2.0 parts of glass fiber, and 0.5-2.0 parts of poly(butyl acrylate). The composite material produced by the invention has advantage of more uniform mixing, and greatly improves the extension and impact resistance of the material.

Owner:东莞市骄阳塑胶科技有限公司

Steel pipe high-ductility combination column and construction method thereof

PendingCN114517558ACompensation for the disadvantage of insufficient axial ductilityImprove ductilityStrutsClimate change adaptationEngineeringFiber-reinforced composite

The invention relates to a steel pipe high-ductility combination column and a construction method thereof. Comprising an outer steel pipe, an inner corrugated pipe and a plurality of connecting plates, a plurality of first hanging strips are evenly fixed to the inner circumferential face of the outer steel pipe, the cross section of each first hanging strip is in a C shape, and the inner corrugated pipe and the connecting plates are made of fiber reinforced composite materials; a corrugated groove in the inner corrugated pipe is spiral, second hanging strips corresponding to the first hanging strips one to one are integrally fixed to the peripheral face of the corrugated groove, a plurality of through holes penetrating through the inside and the outside are evenly distributed in the corrugated pipe, and the connecting plate comprises two layers of corrugated plates and two inserting plates symmetrically connected to the two ends of the two layers of corrugated plates. The connecting plates are inserted between the first hanging strips and the second hanging strips which correspond to each other through the inserting plates, the fiber concrete is poured into the outer steel pipes, cavities in the outer steel pipes are filled with the fiber concrete through the positions between any upper and lower adjacent corrugated plates and through the through holes, multi-direction high ductility is achieved, vibration energy can be effectively absorbed, structural damage is avoided, and the service life of the connecting plates is prolonged. And all parts are tightly connected and are not easy to separate.

Owner:HENAN UNIV OF URBAN CONSTR

A kind of method for preparing nickel-based alloy welding wire

ActiveCN103949805BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

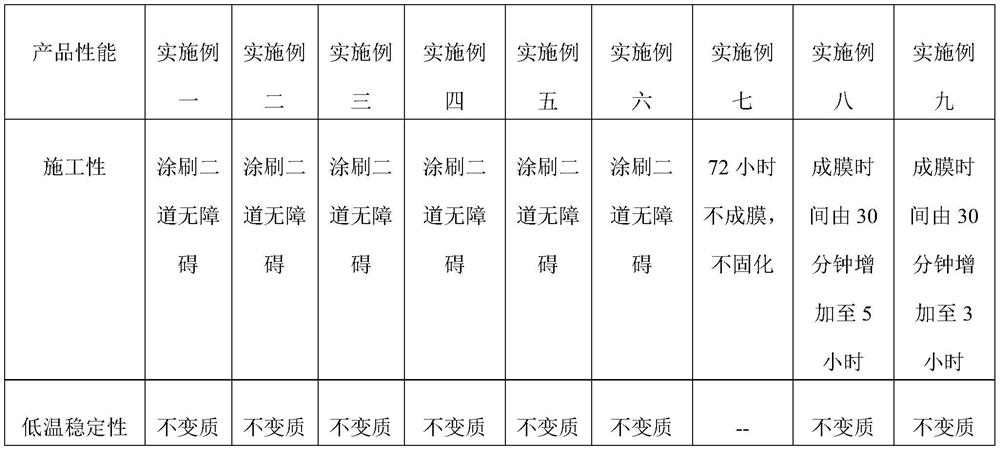

Compression-resistant waterproof environment-friendly coating

ActiveCN114854264AAchieve waterproof effectImprove extensionAnti-corrosive paintsPolyurea/polyurethane coatingsChemical storageToluene diisocyanate

The invention relates to a compression-resistant waterproof environment-friendly coating which is prepared from 20 to 40 parts of film-forming resin, 3 to 5 parts of 2, 4-toluene diisocyanate, 1 to 2 parts of ethylenediamine, 15 to 35 parts of pigment and filler, 2 to 4 parts of auxiliaries, 0.05 to 0.1 part of flexibilizer, 2 parts of graphene nanosheets, 8 to 12 parts of nano ceramic, 5 to 10 parts of hollow glass beads and 10 to 20 parts of deionized water, and discloses a preparation method of the compression-resistant waterproof environment-friendly coating. The invention has the following beneficial effects: the coating can realize heat insulation in a manner of reflecting sunlight, the reflectivity to sunlight is up to 90%, the hemispherical emissivity is 0.9, the ductility reaches 105%, and the coating has excellent waterproof performance, outstanding corrosion resistance, strong weatherability and chemical corrosion resistance. The coating can be used for heat insulation of chemical storage tanks, heat insulation of buildings, water resistance, explosion prevention of pipelines in winter and the like, and has the characteristics of strong adhesive force, good flexibility, long service life and the like.

Owner:海威(海南)环境科技有限公司

A kind of preparation method of nickel base alloy welding wire with diameter less than 3mm

ActiveCN103962755BEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a nickel base alloy welding wire. Alloy of the nickel base alloy welding wire comprises, by mass, 0.4%-0.45% of C, 1.0%-1.5% of Mn, 0.15%-1.2% of Si, 0.025% or less of P, 0.02% or less of S, 28%-30% of Cr, 49%-51% of Ni, 0.1% or less of Co, 0.1% or less of Mo, 0.1% or less of Ti, 0.1% or less of Al, 4.0%- 5% of W and the balance being Fe. The method for preparing the nickel base alloy welding wire includes the steps of alloy smelting, electroslag remelting, hot forging and blooming, hot rolling and annealing, acid pickling and coping, cold drawing and hydrogen withdrawing. A CaF2 slag system, an Al2O3 slag system and a CaO slag system are adopted in electroslag remelting. Through the method for preparing the nickel base alloy welding wire, the thin welding wire with the performance meeting requirements can be prepared, and the yield is high.

Owner:JIANGSU TOLAND ALLOY

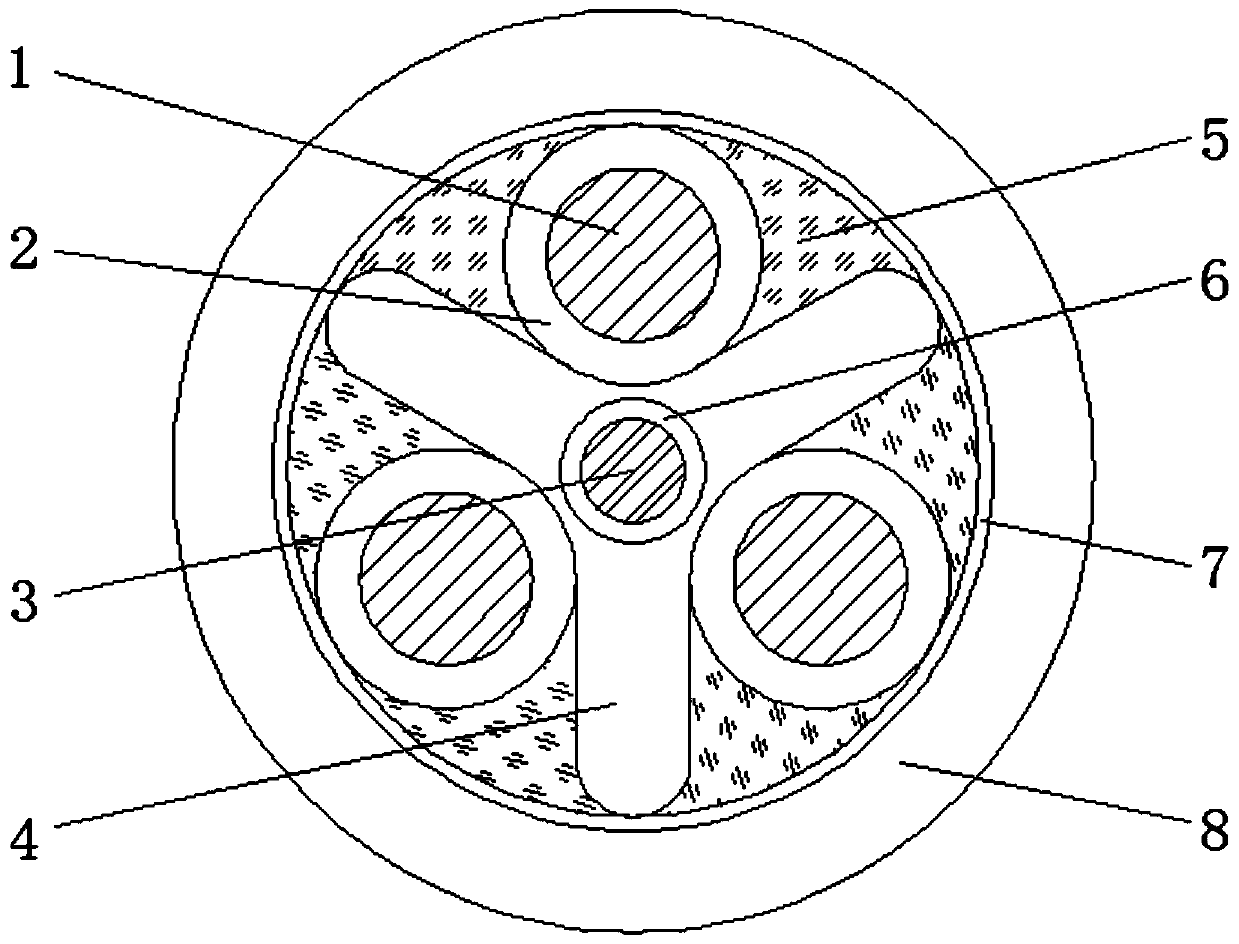

Scandium aluminum alloy conductor low-voltage rubber jacketed flexible cable for offshore wind power generation

ActiveCN110164621ALow costAvoid squeezing each otherRubber insulatorsClimate change adaptationElectrical conductorLow voltage

The invention discloses a scandium aluminum alloy conductor low-voltage rubber jacketed flexible cable for offshore wind power generation, which belongs to the field of wires and cables. The scandiumaluminum alloy conductor low-voltage rubber jacketed flexible cable comprises a cable core, a water-blocking wrapping tape and an outer sheath. The water-blocking wrapping tape is wrapped on the outerside of the cable core. The outer sheath is extruded on the outer side of the water-blocking wrapping tape. The cable core comprises three power wire cores, a plurality of supporting frames and a ground wire cores. The ground wire cores are arranged in the center of the interior of the cable core. The centers of the interiors of the ground wire cores are filled with a ground wire core conductor.The outer side of the ground wire core conductor is extruded with a ground wire core insulating sleeve. The outer sides of the ground wire cores are sleeved with supporting frames. The three power wire cores are arranged between the supporting frames respectively. Cable cores are effectively fixed and supported by adopting the spirally arranged supporting frames, so that the mutual extrusion deformation among the cable cores is avoided. The structural strength, the ductility, the tear resistance and the like of the cable core of the scandium aluminum alloy conductor low-voltage rubber jacketedflexible cable are effectively improved. The defect that a traditional cable is poor in bending performance is overcome. The scandium aluminum alloy conductor low-voltage rubber jacketed flexible cable is effectively suitable for a low-voltage cable and is convenient to popularize for a long period of time.

Owner:ANHUI LINGYU CABLE TECH

Bacteriostatic aluminum alloy for automobile pipeline and processing method of bacteriostatic aluminum alloy

InactiveCN109628806ACorrosion resistanceImprove extensionAntifouling/underwater paintsPaints with biocidesChemical compositionImpurity

The invention discloses a bacteriostatic aluminum alloy for an automobile pipeline. The bacteriostatic aluminum alloy is prepared from chemical components including, by weight, 0.4%-0.5% of Si, 0.1%-0.25% of Fe, 0.15%-0.25% of Mn, 2.5%-4.5% of Mg, 0.1%-0.25% of Zn, 0.05%-0.1% of Sc, 0.45%-0.8% of Li, 0.01%-0.1% of Cu, 0.01%-0.1% of Cr and the balance Al and inevitable impurities. Multiple elementssuch as Sc, Li and the like are added on the basis of a traditional aluminum alloy, so that the aluminum alloy has the characteristics of corrosion resistance, high ductility and the like, surface treatment is performed on the aluminum alloy by the aid of a heat-insulating bacteriostatic powder coating, the coating is prepared from main components including silica powder and calcined shell powder, and thus the alloy has the very good heat-insulating effect; and meanwhile, nano titanium dioxide is added, so that the alloy has the good bacteriostatic effect, and the long-term bacteriostatic effect can be 60% or above.

Owner:安徽宏宇铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com