Polycarbonate composite material

A technology of polycarbonate and composite materials, which is applied in the field of organic chemistry, can solve the problems of reduced ductility, small increase, and influence on product thermal deformation temperature and flow properties, etc., to achieve improved ductility and impact resistance, and uniform mixing Effect

Inactive Publication Date: 2019-01-11

东莞市骄阳塑胶科技有限公司

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

PC resin has excellent mechanical properties, impact resistance and electrical insulation properties, making it one of the ideal materials for plastic parts such as automobiles and home appliances; in addition, PC is a resin with high light transmittance. Widely used in lighting lampshades, automotive tachometers, lamps, billboards, advertising boxes, resin glass, liquid crystal displays and other fields. Adding fillers to polycarbonate can obtain better rigidity, but the ductility will be greatly reduced

In order to improve the impact strength of the material, there is currently a technology to improve the impact strength of the composition by adding an impact modifier, but it will affect the heat distortion temperature and flow properties of the product, and there are also technologies through the selection of filler size or surface treatment To improve the impact strength, but the increase is not large, the effect is not obvious

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

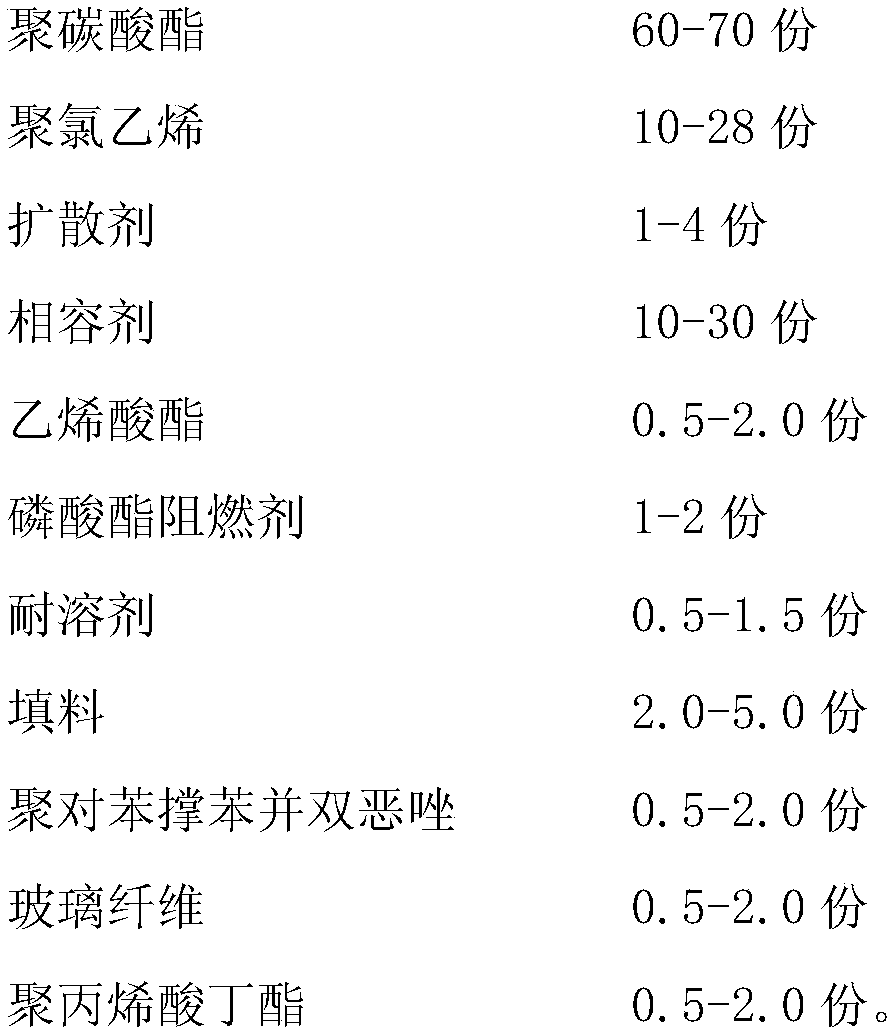

[0013] A kind of polycarbonate composite material, the consumption (mass parts) of each raw material is:

[0014]

Embodiment 2

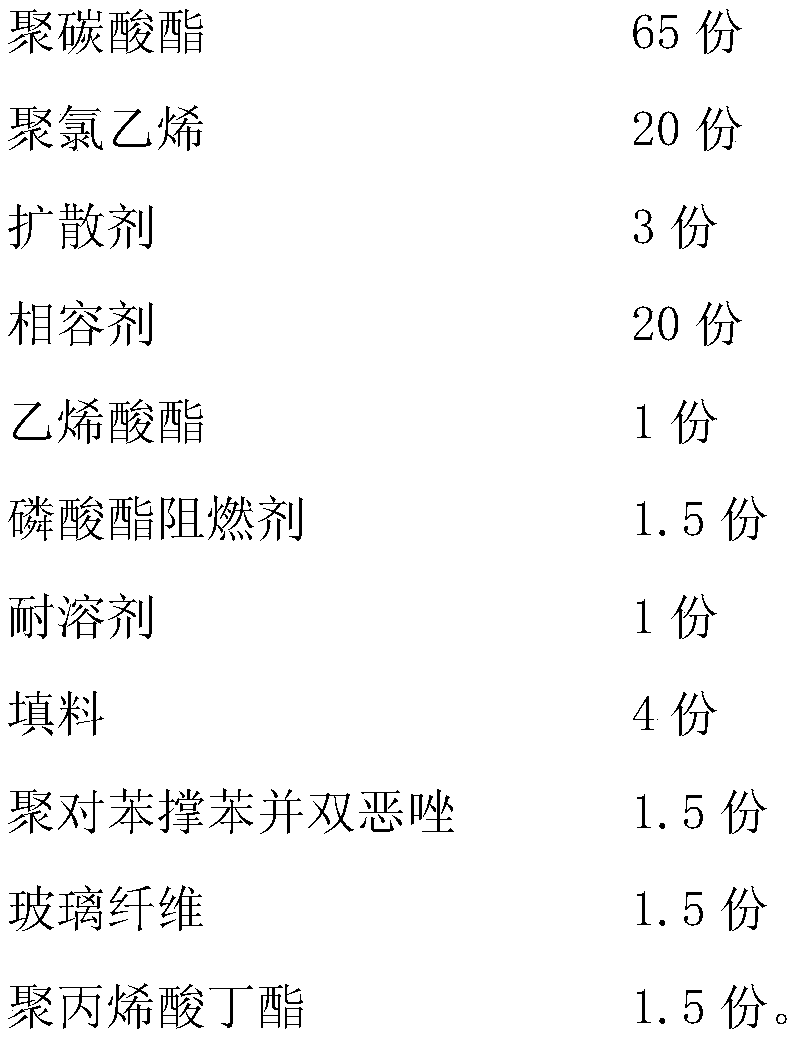

[0016] A kind of polycarbonate composite material, the consumption (mass parts) of each raw material is:

[0017]

[0018]

Embodiment 3

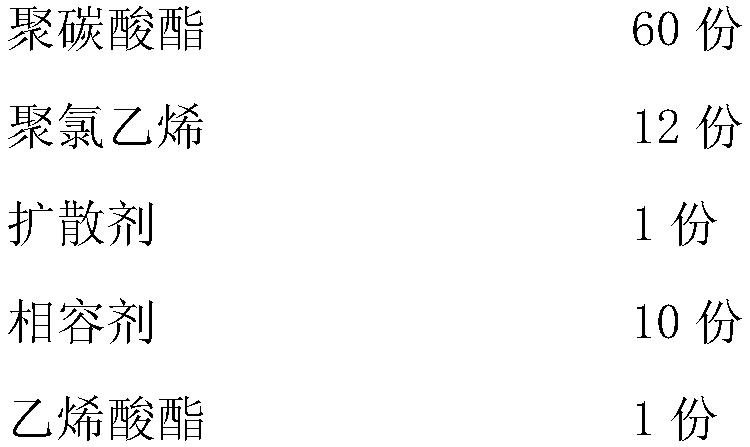

[0020] A kind of polycarbonate composite material, the consumption (mass parts) of each raw material is:

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a polycarbonate composite material, which belongs to the field of an organic chemical polymer. The polycarbonate composite material comprises the following main raw materials(by in parts by mass): 60-70 parts of polycarbonate, 10-28 parts of polyvinyl chloride, 1-4 parts of a diffusing agent, 0-30 parts of a compatibilizer, 0.5-2.0 of vinyl acid ester, 1-2 parts of a phosphate flame retardant, 1-2 parts of the phosphate flame retardant, 2.0-5.0 parts of a filler, 0.5-2.0 parts of poly(p-phenylene benzobisoxazole), 0.5-2.0 parts of glass fiber, and 0.5-2.0 parts of poly(butyl acrylate). The composite material produced by the invention has advantage of more uniform mixing, and greatly improves the extension and impact resistance of the material.

Description

technical field [0001] The invention belongs to the field of organic chemistry, and in particular relates to a polycarbonate composite material. Background technique [0002] Polycarbonate resin, referred to as PC, is a widely used engineering plastic. PC resin has excellent mechanical properties, impact resistance and electrical insulation properties, making it one of the ideal materials for plastic parts such as automobiles and home appliances; in addition, PC is a resin with high light transmittance. Widely used in lighting lampshades, automotive tachometers, car lights, billboards, advertising boxes, resin glass, liquid crystal displays and other fields. Adding fillers to polycarbonate can obtain better rigidity, but the ductility will be greatly reduced. In order to improve the impact strength of the material, there is currently a technology to improve the impact strength of the composition by adding an impact modifier, but it will affect the heat distortion temperatur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L69/00C08L27/06C08L33/08C08L63/00C08K7/14C08K5/521

CPCC08L69/00C08L2205/035C08L27/06C08L33/08C08L63/00C08K7/14C08K5/521

Inventor 李飒王春闯

Owner 东莞市骄阳塑胶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com