Ultrafine ceramic particle Cu based composite material taking Ti2SnC as precursor and preparation method of composite material

A technology of ceramic particles and composite materials, which is applied in the field of ultrafine ceramic particle ultrafine Cu-based composite materials and its preparation, and achieves the effects of simple process, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

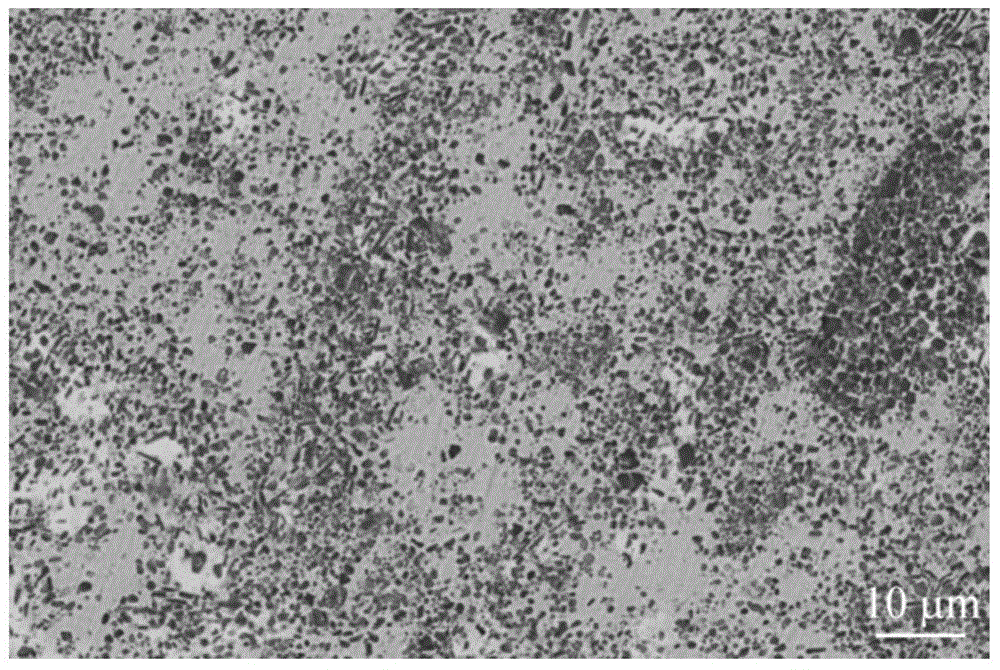

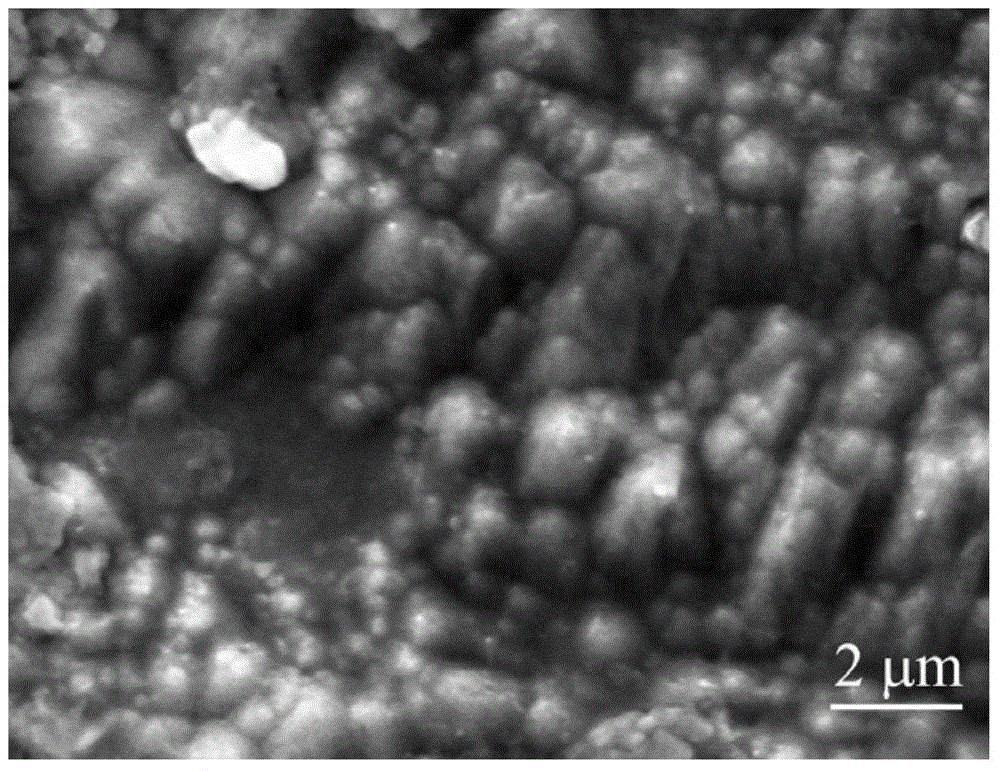

[0020] Weigh Ti with a purity of 98.5% and a particle size of 5 μm 2 2.2 grams of SnC powder, 97.8 grams of Cu powder with a purity of 99.8% and a particle size of 50 μm, after mixing, add 200 grams of agate balls, ball mill the mixture for 2 hours, put the mixed powder into a Φ50 steel mold, and apply a pressure of 120 MPa , compact the powder in the mold, put the above block into a high-temperature furnace, and under the protection of argon, raise the temperature of the furnace to 1100°C at a heating rate of 10°C / min, keep it warm for 30min, and then heat it for 10 The temperature is lowered at a rate of ℃ / min, and after cooling, an ultrafine Cu-based composite material with ultrafine ceramic particles is obtained.

[0021] The measured TiC of the above composite materials 0.5 The particles are about 200-300nm, the Cu crystal grains are about 0.8-1μm, the yield strength of the composite material is 100MPa, the compressive strength is 295MPa, and the elongation is 53%.

Embodiment approach 2

[0023] Weigh Ti with a purity of 98.5% and a particle size of 10 μm 2 7.33 grams of SnC powder, 92.67 grams of Cu powder with a purity of 99.8% and a particle size of 70 μm, after mixing, add 400 grams of agate balls, ball mill the mixture for 2 hours, put the mixed powder into a Φ76 steel mold, and apply a pressure of 250 MPa , compact the powder in the mold, put the block into a high-temperature furnace, and under the protection of argon, raise the temperature of the furnace to 1150°C at a heating rate of 20°C / min, keep it warm for 45min, and then heat it for 30 The temperature is lowered at a rate of ℃ / min, and after cooling, an ultrafine Cu-based composite material with ultrafine ceramic particles is obtained.

[0024] The measured TiC of the above composite materials 0.5 The particles are about 150-200nm, the Cu crystal grains are about 0.3-0.5μm, the yield strength of the composite material is 225MPa, the compressive strength is 562MPa, and the elongation is 46%.

Embodiment approach 3

[0026] Weigh Ti with a purity of 98.5% and a particle size of 7 μm 2 15.12 grams of SnC powder, 84.88 grams of Cu powder with a purity of 99.8% and a particle size of 60 μm, after mixing, add 300 grams of agate balls, ball mill the mixture for 4 hours, put the mixed powder into a Φ50 steel mold, and apply a pressure of 200 MPa , compact the powder in the mold, put the block into a high-temperature furnace, and under the protection of argon, raise the temperature of the furnace to 1170°C at a heating rate of 30°C / min, keep it warm for 60 minutes, and then heat it for 20 The temperature is lowered at a rate of ℃ / min, and after cooling, an ultrafine Cu-based composite material with ultrafine ceramic particles is obtained.

[0027] The measured TiC of the above composite materials 0.5 The particles are about 60-80nm, the Cu crystal grains are about 0.1-0.2μm, the yield strength of the composite material is 335MPa, the compressive strength is 870MPa, and the elongation is 38%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com