High-density polyvinyl chloride light conveying belt and manufacturing method thereof

A light conveyor belt, polyvinyl chloride technology, applied in the direction of conveyors, chemical instruments and methods, transportation and packaging, etc., can solve the problems that cannot meet the needs of the building materials industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0088] Preparation method of high density polyvinyl chloride light conveyor belt

[0089] The second aspect of the present invention provides a kind of preparation method of high-density polyvinyl chloride light conveyor belt as described in the present invention, wherein, comprise the steps:

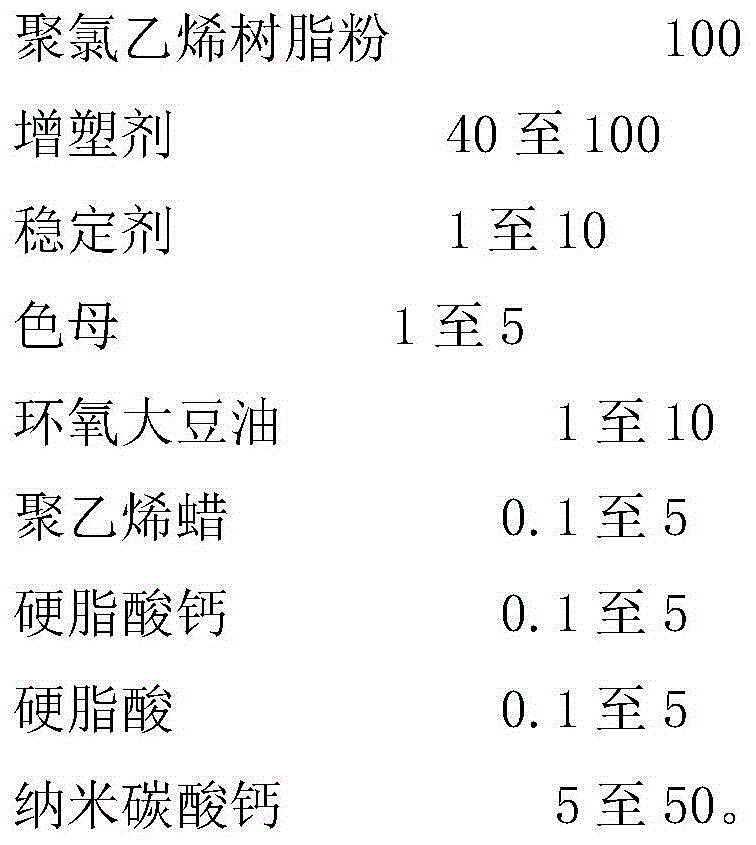

[0090] (1) Provide a high-density polyvinyl chloride resin composition;

[0091] (2) The high-density polyvinyl chloride resin composition is kneaded to obtain a kneaded material;

[0092] (3) After the kneaded material is plasticized, a plasticized material is obtained;

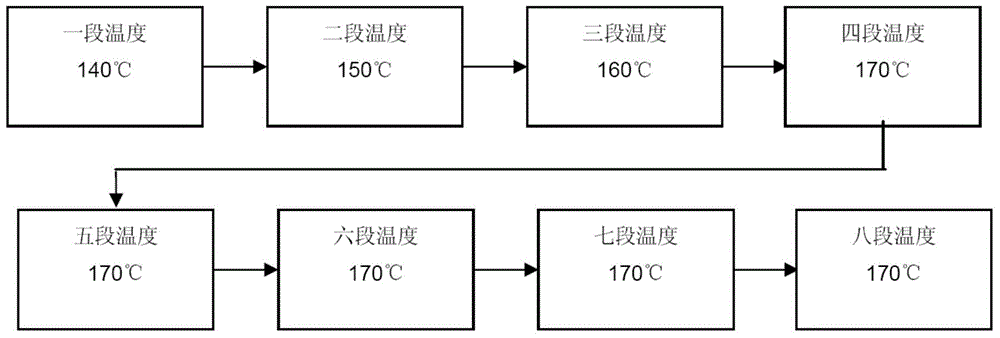

[0093] Wherein, the plasticizing process includes at least three heating stages between 140°C and 160°C and at least five stages of heat preservation between 160°C and 170°C;

[0094] (4) The plasticized material is calendered to obtain a calendered material;

[0095] Wherein, in the calendering process, at least five-stage roller calendering is adopted, including the first roller with a temperature of 160°C to 180...

Embodiment approach

[0125] The prior art uses paste-like polyvinyl chloride material, made by coating and scraping method, and is plasticized under normal pressure. This method forms products, which cannot reach high-density levels.

[0126] In the most preferred embodiment of the present invention, use extruder, calender, and reasonable formula, speed, temperature, and the light-duty conveyer belt that process makes to obtain high-density polyvinyl chloride light-duty conveyer belt.

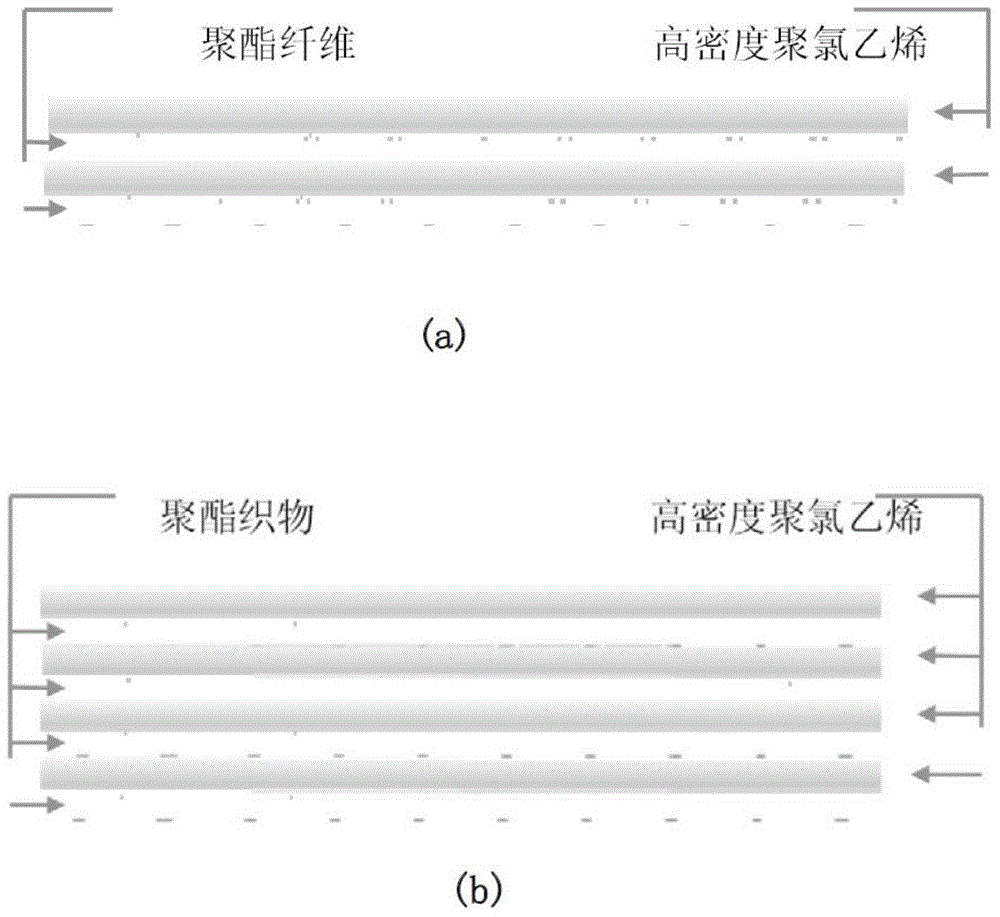

[0127] The thickness of the high-density polyvinyl chloride light conveyor belt of the present invention is 1.6 to 9 mm, and the structure includes one cloth and one glue, two cloths and two glues, three cloths and three glues, and four cloths and four glues. The thickness and structure are set according to the requirements of different industries.

[0128] Beneficial effects of the present invention:

[0129] Existing light-duty conveyor belts are manufactured using traditional techniques, that is, using pasty po...

Embodiment 1

[0140] The present invention is applicable to the fields such as the building material industry, etc. that require high compression deformation resistance for light-duty conveyor belts, such as tile polishing systems. Arrange 43 polyester multifilaments with a specification of 1000D in the horizontal direction, and arrange 23 polyester monofilaments with a diameter of 0.3 mm in the weft direction. The warp and weft density of the base fabric is 43*23A28 / inch, that is, 43 radially arranged per square inch. It is 1000D polyester multifilament, 23 polyester monofilaments with a diameter of 0.3 mm are arranged in the weft direction, and 1 out of every 8 radial fibers with a diameter of 20D is evenly arranged in the 43 polyester fibers in the warp direction. carbon fiber.

[0141] A high-density light conveyor belt, the thickness of which is required to be 2 mm, a high-density light conveyor belt with two cloth and two rubber structures, including polyester ordinary fabrics, polyes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com