TPU light conveyor belt for printing and dyeing industry and manufacturing method thereof

A light conveyor belt, industry-leading technology, applied in the field of conveyor belt manufacturing, can solve problems such as fiber length elongation, running length, belt surface damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

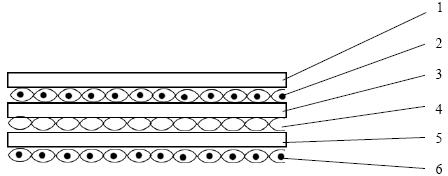

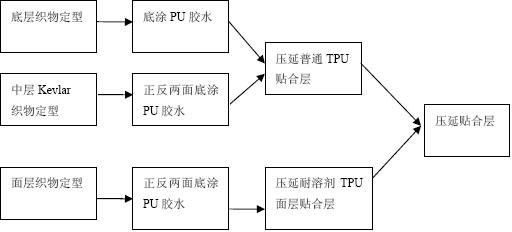

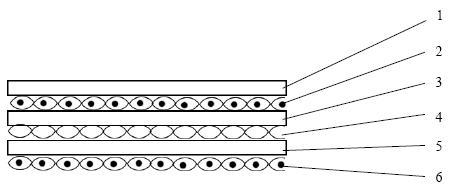

[0030] figure 1 As shown in the structural diagram of the TPU conveyor belt for the printing and dyeing industry, the TPU light conveyor belt for the printing and dyeing industry includes three layers of reinforced skeleton, one layer of covering surface layer and two layers of covering and bonding layer, wherein the first and third layers of reinforced skeleton adopt Polyester woven fabric, the warp direction yarn adopts ultra-low shrinkage polyester filament with a linear density of 1000D, the density is 52-58 threads / inch, and the weft direction adopts 0.25mm ultra-low shrinkage polyester monofilament, the density is 20-25 root / inch; the second layer of reinforced skeleton adopts Kevlar fiber woven fabric, the warp direction yarn adopts Kevlar filament with a linear density of 1000D, and the density is 20-25 strands / inch, and the weft direction adopts a linear density of 3 strands of 21S polyester short The density is 10-15 strands / inch; the covering layer is made of black ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com